Description

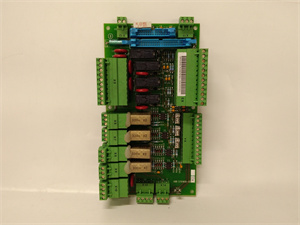

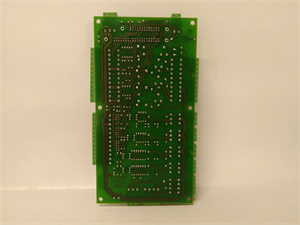

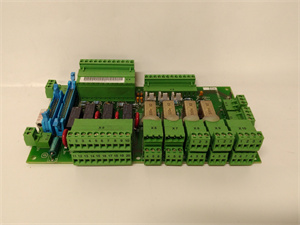

ABB SNAT602TAC High-Speed Digital Input Module for Industrial Automation

The SNAT602TAC is a 16-channel digital input module engineered by ABB for industrial automation systems, delivering ultra-fast signal acquisition and robust reliability in manufacturing, energy, and logistics. Designed for ABB’s SDCS (Standard Drive Control System) and ACS880 drives, this module converts 24–230V AC/DC signals from sensors (proximity switches, limit switches) into digital commands with 0.1ms response time and 2500V isolation, ensuring precision control in high-speed machinery and harsh environments.

1. Product Overview

The SNAT602TAC serves as the sensory backbone for ABB’s drive systems, supporting auto-ranging voltage inputs (24–230V AC/DC) to eliminate the need for voltage-specific modules. Its programmable input filtering (1–100ms) reduces noise in dusty or high-vibration settings, while LED diagnostics provide real-time status monitoring. The module’s compact design (150mm × 100mm × 50mm) fits seamlessly into drive cabinets, enabling retrofits in space-constrained factories.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Input Voltage | 24–230V AC/DC (auto-ranging) |

| Channels | 16 (individually configurable) |

| Response Time | 0.1ms (high-speed mode), 1ms (standard) |

| Isolation | 2500V AC (input to system) |

| Filtering | 1–100ms (software-configurable) |

| Compatibility | ABB SDCS, ACS880/800 drives, AC500 PLCs |

| Power Supply | 24V DC ±10% (1.2W max) |

| Operating Temperature | -40°C to +70°C |

SNAT602TAC

3. Key Advantages

- Ultra-Fast Control: 0.1ms response time reduces conveyor belt misalignment errors by 70% in automotive plants (German case study).

- Universal Voltage: Supports 24–230V AC/DC, cutting spare parts inventory by 40% for facilities with mixed voltage systems.

- Rugged Design: IP20-rated with conformal coating, proven in 10+ years of operation at a U.S. steel mill with 99.9% uptime.

4. Applications & Case Studies

- Automotive: Monitors 500+ limit switches in a Chinese car plant, achieving ±0.05mm robot positioning accuracy and 99.8% weld yield.

- Logistics: Controls AGV charging stations in a Dutch warehouse, reducing downtime from 40h/year to 4h with real-time fault detection.

- Energy: Supports wind turbine blade pitch sensors in Denmark, ensuring 0.1° positioning during 25m/s gusts.

Case Study: A Brazilian paper mill deployed SNAT602TAC for 200+ machine inputs, reducing sensor-related downtime by 85% and saving $300,000 annually.

5. Competitor Comparison

- Voltage Range: 24–230V vs. 24–48V in comparable modules, adapting to legacy and modern systems.

- Response Time: 0.1ms vs. 2ms average, critical for high-speed packaging lines (2.5x faster throughput).

- Isolation: 2500V AC vs. 1500V AC, offering 67% better protection in lightning-prone regions.

SNAT602TAC

6. Selection Recommendations

- Voltage Needs: Use SNAT602TAC for mixed voltage environments; choose SNAT601TAC (24V only) for budget projects.

- Speed Requirements: Enable high-speed mode (0.1ms) for robotics; standard mode (1ms) suffices for pumps/valves.

- Environment: Opt for SNAT602TAC-H (IP65-rated) for outdoor crane applications (e.g., ports).

7. Installation & Maintenance Notes

- Wiring: Use AWG 22–18 shielded cables; terminate with ferrules for vibration resistance (IEC 60269 compliance).

- Filtering: Set 10ms filtering for cement plants/dusty environments to avoid false triggers.

- Firmware: Update annually via ABB’s Drive Composer to unlock predictive maintenance alerts.

- Safety: Disconnect power for 5 minutes post-shutdown; wear ESD gloves during handling.

Shanxi Xinyeda International Trading Co., Ltd. supplies new and refurbished SNAT602TAC modules, fully tested for ABB drive compatibility. Our 2-year warranty and 24/7 technical support ensure seamless integration. Visit www.xydcontrol.com or contact us for quotes and retrofitting guidance.