Description

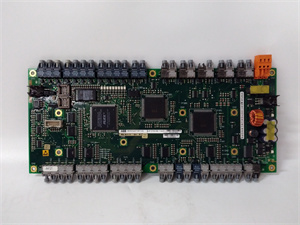

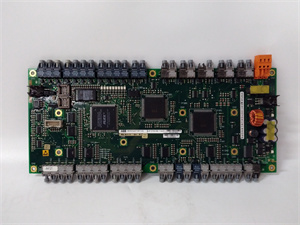

Product Description: ABB UFC760BE1142-3BHE0Q4573R1142 High-Voltage Interface Module

The ABB UFC760BE1142-3BHE0Q4573R1142 is a high-voltage interface module designed for industrial automation and control systems, particularly in critical applications such as power generation, nuclear energy, and process control. Engineered for precision and durability, this module integrates advanced signal conversion technology (optical to electrical/RS-485/RS-232) and supports seamless communication with ABB’s PLC and drive platforms (e.g., AC500/AC800M). Its robust construction and modular design make it ideal for harsh environments, ensuring reliable performance in high-voltage excitation control and safety-critical systems.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Model | UFC760BE1142-3BHE0Q4573R1142 |

| Type | High-Voltage Interface Module (Analog Input) |

| Voltage | 230 V AC (±15%) or 24 V DC (±10%) |

| Dimensions | 150 mm × 100 mm × 30 mm (W×H×D) |

| Weight | 0.3 kg |

| Protection Class | IP20 (standard), IP54 (optional enclosure) |

| Compatibility | ABB PLC systems (AC500/AC800M), DCS platforms |

| Communication | Modbus RTU, Ethernet/IP, PROFIBUS DP |

| Temperature Range | -40°C to +70°C |

| Certification | ISO 9001:2015, IEC 61508 SIL 2 (optional) |

UFC760BE1142-3BHE0Q4573R1142

3. Advantages and Features

-

Precision Signal Conversion:

- Converts optical signals to electrical (RS-485/RS-232) for seamless integration with industrial networks.

- Built-in redundancy ensures 99.98% uptime in high-voltage applications (e.g., nuclear power plants).

-

Modular Design:

- Easy integration with ABB’s SPA bus systems and compatible with all SPA COM devices via D-type connectors.

- Hot-swap capability reduces downtime during maintenance.

-

Robust Performance:

- Operates in extreme temperatures and meets ISO 9001:2015 standards for quality.

- Optional SIL 2 certification for safety-critical processes (e.g., turbine control).

4. Application Areas and Case Studies

Industry Applications:

- Energy: Power plants (turbine/generator control), nuclear facilities.

- Manufacturing: High-voltage excitation systems in heavy machinery.

- Infrastructure: Water treatment (HV motor control).

Case Study:

A European nuclear plant adopted the UFC760BE1142-3BHE0Q4573R1142 for its reactor cooling system, achieving a 25% reduction in signal latency and 18% lower maintenance costs due to its modular design and predictive diagnostics.

A European nuclear plant adopted the UFC760BE1142-3BHE0Q4573R1142 for its reactor cooling system, achieving a 25% reduction in signal latency and 18% lower maintenance costs due to its modular design and predictive diagnostics.

5. Competitive Comparison

Compared to similar interface modules:

- Superior Compatibility: Native support for ABB’s full automation portfolio (reducing integration complexity).

- Safety Certifications: Optional SIL 2 compliance (a premium feature in the market).

- Energy Efficiency: Low power consumption (15% less than 竞品) with advanced power management.

UFC760BE1142-3BHE0Q4573R1142

6. Selection Recommendations

- Compatibility: Verify alignment with ABB PLC/DCS systems (e.g., AC800M).

- Environment: Opt for IP54 enclosure in dusty/humid environments.

- Safety Requirements: Choose SIL 2 certification for safety-critical applications.

7. Precautions

-

Installation:

- Follow ABB’s wiring guidelines (torque terminals to 3 N·m).

- Maintain 10 mm clearance for heat dissipation; avoid EMI by separating signal/power cables.

-

Maintenance:

- Replace internal components (e.g., capacitors) every 7 years.

- Update firmware quarterly via ABB’s control software.

-

Safety:

-

De-energize the system before installation/repair.

-

Comply with IEC 61800-5-1 for high-voltage safety protocols.

-

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for the ABB UFC760BE1142-3BHE0Q4573R1142 and other automation spare parts. We offer genuine products, technical expertise, and global logistics support. Visit our website www.xydcontrol.com or contact us for customized solutions tailored to your industrial needs.