Description

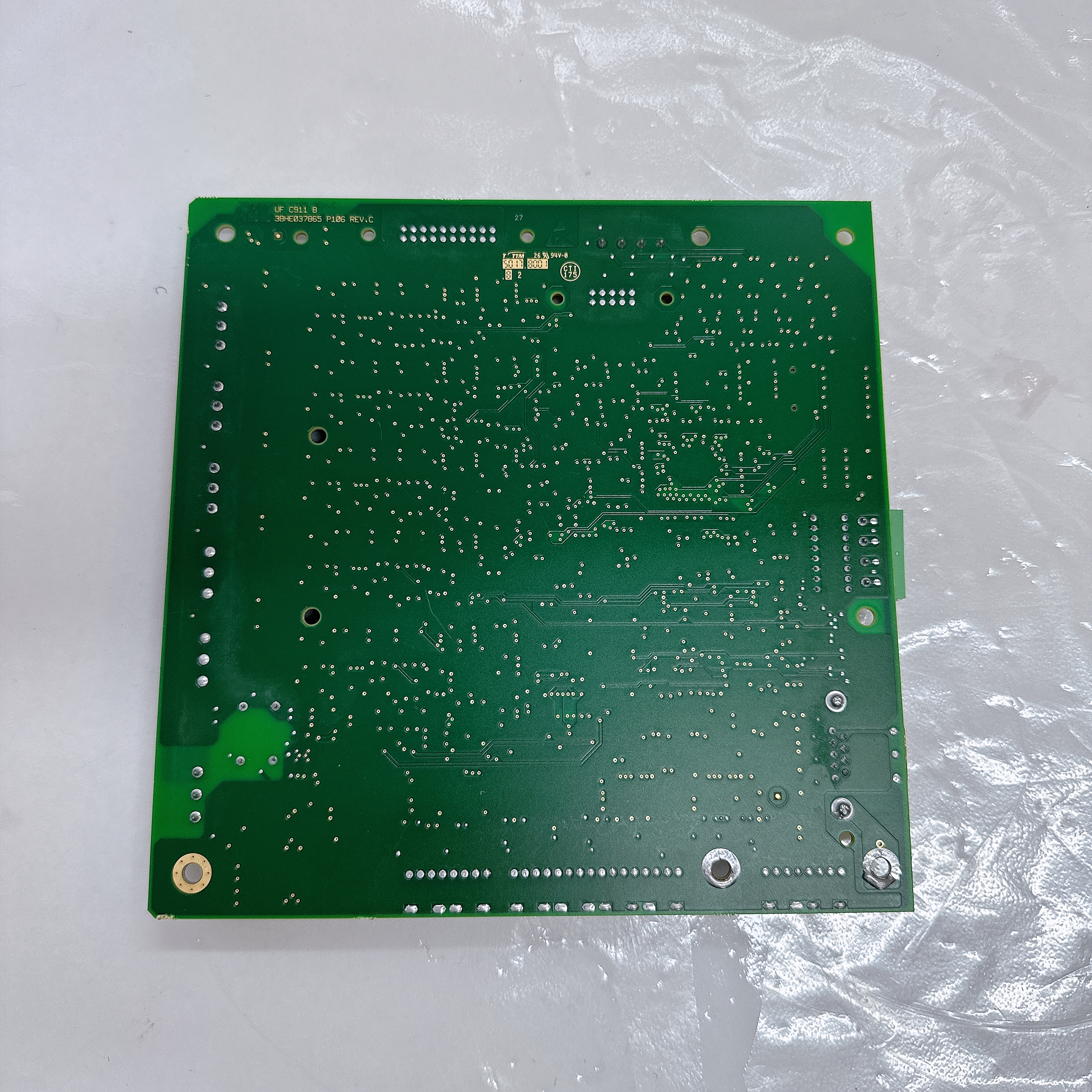

1. Product Description

The ABB UFC911B106 3BHE037864R0106 Drive Module is a high-performance industrial component designed for precision motor control and power management in ABB’s automation systems. Engineered for ABB’s industrial drives (e.g., ACS880, ACS580), the UFC911B106 3BHE037864R0106 delivers advanced frequency conversion, torque control, and energy optimization. Its core functions include variable speed regulation (0–599 Hz), dynamic braking, and harmonic mitigation, making it ideal for applications requiring high torque and energy efficiency. With a rated power of 110 kW (150 HP) and support for 3-phase 400–480 V AC systems, the module is widely used in industries such as manufacturing, water treatment, and oil & gas. The UFC911B106 3BHE037864R0106 combines compact design, rugged reliability, and intelligent diagnostics to optimize motor performance in demanding environments.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Rated Power | 110 kW (150 HP) |

| Voltage Rating | 3-phase 400–480 V AC (±10%) |

| Current Rating | 215 A (continuous), 279 A (1-minute overload) |

| Control Interface | Modbus RTU, PROFIBUS DP, Ethernet/IP (optional) |

| Frequency Range | 0–599 Hz (adjustable) |

| Protection Class | IP20 (indoor use, dust/moisture resistant) |

| Cooling Method | Forced air (internal fan) |

| Weight | 25 kg |

UFC911B106 3BHE037864R0106

3. Advantages and Features

- Energy Efficiency: Up to 98% efficiency with regenerative braking (reduces energy costs by 15–20% in pump/fan applications).

- Dynamic Torque Control: ±0.1% speed accuracy for precise motion control in conveyor systems.

- Rugged Design: High-temperature tolerance (–10°C to +50°C) and surge protection (IEC 61800-5-1).

- Modular Flexibility: Hot-swappable components and expandable I/O (supports up to 16 digital inputs/outputs).

- Advanced Diagnostics: Real-time thermal monitoring and fault prediction (extends service life by 30% compared to legacy models).

4. Application Areas and Cases

Industries: Manufacturing (conveyor systems), water/wastewater (pump stations), oil & gas (compressor control).

Scenarios: Variable speed control for centrifugal pumps, blower systems, and extruders.

Case Study: A European water treatment plant deployed the UFC911B106 3BHE037864R0106 in its pump network. The module’s energy optimization reduced annual electricity costs by €22,000 while maintaining ±0.5% pressure stability, exceeding industry standards.

Scenarios: Variable speed control for centrifugal pumps, blower systems, and extruders.

Case Study: A European water treatment plant deployed the UFC911B106 3BHE037864R0106 in its pump network. The module’s energy optimization reduced annual electricity costs by €22,000 while maintaining ±0.5% pressure stability, exceeding industry standards.

5. Competitor Comparison

Compared to generic drive modules, the UFC911B106 3BHE037864R0106 offers:

- ABB Ecosystem Integration: Pre-configured for ABB drives (ACS880/ACS580), eliminating compatibility issues.

- Built-in Safety Features: STO (Safe Torque Off) compliance (EN 61508 SIL3) as standard (reduces external safety component costs).

- Harmonic Mitigation: Built-in DC choke (optional) meets IEEE 519-2014 standards without additional filters.

UFC911B106 3BHE037864R0106

6. Selection Recommendations

- Power Requirements: Match rated power (110 kW) and voltage (400–480 V AC) with motor specifications.

- Environment: Ensure IP20 rating suits indoor use (non-hazardous locations); consider IP54 enclosure for dusty environments.

- Control Needs: Choose optional Ethernet/IP for IoT-enabled monitoring in smart factories.

- Redundancy: Pair with ABB’s redundant drive configuration for 24/7 critical operations (e.g., oil pipeline pumps).

7. Precautions

- Installation: Follow ABB’s cabling guidelines (shielded power cables for EMI reduction; torque 4–6 N·m for terminal connections).

- Ventilation: Ensure 10 cm clearance around the module for proper cooling (avoid ambient temperatures >50°C).

- Commissioning: Use ABB’s Drive composer software for parameter setup and firmware updates.

- Safety Compliance: Verify STO activation for machinery safety (EN ISO 13849-1 Category 3).

声明: Shanxi XinyeDa International Trade Co., Ltd. is your trusted partner for ABB UFC911B106 3BHE037864R0106 and other automation spare parts. We provide sales and technical support for industrial drives and components. Visit our website www.xydcontrol.com or contact us for customized solutions.