Description

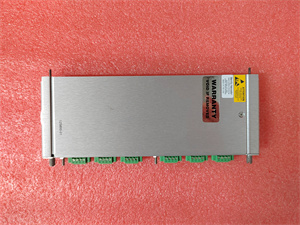

BENTLY NEVADA 125800-01 Keyphasor I/O Module

1. Product Description

The BENTLY NEVADA 125800-01 Keyphasor I/O Module is a compact, high-performance solution designed for the BENTLY Nevada 3500/25 Enhanced Keyphasor system. This two-channel module interfaces with proximity probes or magnetic pickups to detect shaft keyphasor marks, converting analog signals into digital triggers for precise rotational synchronization. It plays a critical role in machinery protection systems by enabling accurate vibration analysis, phase-locked monitoring, and overspeed detection. With internal terminations and a half-height form factor, the module ensures seamless integration into existing 3500 series racks, supporting applications such as turbine control, compressor health monitoring, and rotating equipment diagnostics.

The BENTLY NEVADA 125800-01 Keyphasor I/O Module is a compact, high-performance solution designed for the BENTLY Nevada 3500/25 Enhanced Keyphasor system. This two-channel module interfaces with proximity probes or magnetic pickups to detect shaft keyphasor marks, converting analog signals into digital triggers for precise rotational synchronization. It plays a critical role in machinery protection systems by enabling accurate vibration analysis, phase-locked monitoring, and overspeed detection. With internal terminations and a half-height form factor, the module ensures seamless integration into existing 3500 series racks, supporting applications such as turbine control, compressor health monitoring, and rotating equipment diagnostics.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| System Compatibility | BENTLY Nevada 3500/25 series systems |

| Input Channels | 2 channels (keyphasor signals) |

| Input Signal Type | Proximity probes or magnetic pickups |

| Output Signal | Digital keyphasor triggers |

| Power Supply | 100–240 VRMS (via 3500 rack) |

| Frequency Range | 1 Hz–100 kHz |

| Operating Temperature | 0°C to +65°C (ambient) |

| Storage Temperature | -40°C to +85°C |

| Dimensions | 24.2 cm x 11.2 cm x 2.5 cm (H x W x D) |

| Weight | 0.38 kg |

Bently 125800-01

3. Advantages and Features

- Dual-Channel Flexibility: Simultaneously processes two keyphasor signals for redundant or dual-shaft applications.

- API 670 Compliance: Meets American Petroleum Institute standards for machinery protection systems.

- Wide Temperature Range: Operates reliably in extreme conditions, with a storage temperature range of -40°C to +85°C.

- Remote Configuration: Allows adjustments to alarm setpoints and filters via connected software, reducing on-site visits.

- High Precision: Supports up to eight keyphasor signals in paired configurations for advanced rotational analysis.

4. Application Areas and Use Cases

The 125800-01 is widely used in:

The 125800-01 is widely used in:

- Power Generation: Turbine and generator rotational monitoring.

- Oil and Gas: Compressors and pumps in offshore platforms.

- Manufacturing: High-speed machinery synchronization.

Case Study: A European power plant reduced unplanned downtime by 15% by deploying this module to detect shaft misalignment in gas turbines, enabling proactive maintenance.

5. Competitor Comparison

Compared to similar modules, the 125800-01 offers:

Compared to similar modules, the 125800-01 offers:

- Higher Channel Density: Two channels vs. single-channel alternatives.

- Extended Temperature Range: Storage capacity up to +85°C, exceeding most competitors’ limits.

- API Compliance: Built-in support for industry-standard safety requirements without additional hardware.

-

Bently 125800-01

6. Selection Recommendations

- System Requirements: Ensure compatibility with BENTLY’s 3500/25 series hardware and software.

- Environmental Factors: Choose this module for applications with fluctuating temperatures or remote monitoring needs.

- Channel Needs: Opt for the 125800-01 for dual-channel setups; consider single-channel variants for simpler configurations.

7. Precautions

- Signal Calibration: Regularly verify sensor alignment and signal integrity to maintain accuracy.

- Power Stability: Use filtered power to avoid voltage spikes affecting module performance.

- Software Security: Leverage the 3500 system’s password protection to restrict unauthorized configuration changes.

山西鑫业达国际贸易有限公司 provides the BENTLY NEVADA 125800-01 Keyphasor I/O Module and automation solutions. Visit www.xydcontrol.com for technical support and product inquiries.