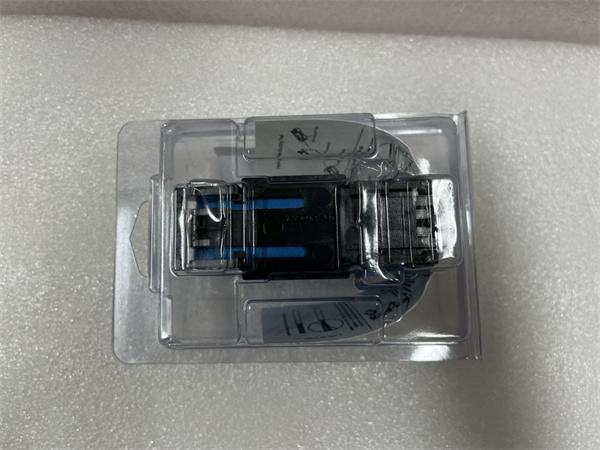

Description

BENTLY NEVADA 330180-51-00

1. Product Description

The BENTLY NEVADA 330180-51-00 is an 8 mm Proximitor® sensor designed for non-contact eddy current vibration and displacement monitoring of rotating machinery. As part of the 3300 XL Series, this sensor converts distance measurements into proportional analog signals, enabling real-time condition assessment of shafts, bearings, and machinery components. It supports dynamic vibration analysis, static position monitoring, and speed measurements, making it ideal for critical applications in oil & gas, power generation, and manufacturing.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Measurement Type | Vibration, displacement, shaft speed |

| Probe Diameter | 8 mm (0.315 inches) |

| Linear Range | 0.51–9.53 mm (0.020–0.375 inches) |

| Output Signal | 4–20 mA analog |

| Power Supply | 18–36 VDC (via Proximitor system) |

| Temperature Range | -40°C to +121°C (-40°F to +250°F) |

| RFI/EMI Immunity | High resistance without shielded conduit |

| Mounting Options | DIN rail or panel mount |

| Dimensions | 8.13 cm × 6.12 cm × 6.35 cm |

| Weight | 0.25 kg |

BENTLY 330180-51-00

3. Advantages and Features

- Non-Contact Design: Eliminates mechanical wear and ensures long-term reliability.

- API 670 Compliance: Meets American Petroleum Institute standards for accuracy and stability.

- Interchangeability: Probe, extension cable, and sensor components are fully interchangeable without recalibration.

- Harsh Environment Tolerance: Operates in extreme temperatures and high-vibration settings.

- Space-Saving DIN Mount: Simplifies installation in compact control panels.

4. Application Areas and Cases

- Oil & Gas: Monitoring compressor shaft alignment in offshore platforms.

- Power Generation: Detecting turbine bearing wear in thermal power plants.

- Manufacturing: Tracking conveyor belt pulley vibrations in steel mills.

- Case Study: A Middle Eastern petrochemical plant reduced maintenance costs by 30% using the 330180-51-00 to predict pump seal failures.

5. Competitor Comparison

- Higher Accuracy: ±0.1% linearity compared to industry-standard ±0.5%.

- Extended Compatibility: Works with BENTLY 3300/3500 systems and third-party controllers.

- Cost-Effective Installation: Reduces labor costs with plug-and-play DIN rail mounting.

BENTLY 330180-51-00

6. Selection Recommendations

- Probe Size: Choose 8 mm for standard applications; use 5 mm probes for confined spaces.

- Temperature Requirements: Opt for ETR (Extended Temperature Range) models for -55°C to +177°C environments.

- Safety Compliance: Verify ATEX/IECEx certifications for hazardous zones.

7. Precautions

- Cable Shielding: Use twisted-pair, shielded cables to prevent signal interference.

- Gap Setting: Maintain 1.5–2 mm probe-to-target gap for optimal performance.

- Calibration: Perform annual checks using BENTLY’s 3500 System Software.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for BENTLY NEVADA 330180-51-00 and automation spare parts. Visit www.xydcontrol.com or contact us for sales and technical support.