Description

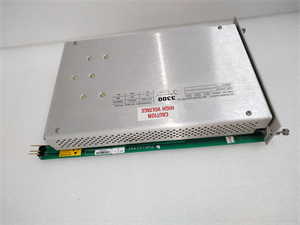

BENTLEY NEVADA 85515-02 Vibration Monitoring Module

The BENTLEY NEVADA 85515-02 is a high-performance vibration monitoring module designed for industrial machinery health management systems. Part of the Bentley Nevada 3500 Series, this module provides real-time vibration analysis and fault detection for rotating equipment such as turbines, compressors, and pumps. It interfaces with accelerometers or proximity probes to convert raw signals into actionable data, enabling predictive maintenance and reducing unplanned downtime.

1. Product Description

The 85515-02 is a single-channel, rack-mountable module that supports both velocity and acceleration measurements. It features advanced signal conditioning and filtering capabilities to eliminate noise and ensure accurate readings in harsh environments. With programmable alarm thresholds and 4-20 mA analog outputs, it integrates seamlessly with control systems for automated response to 异常 conditions. The module is backward compatible with legacy 3500 Series racks, making it an ideal upgrade for existing installations.

2. Key Technical Parameters

| Parameter | Specification |

|---|---|

| Channels | 1 (expandable via paired configurations) |

| Input Signal Types | Velocity (IEPE accelerometers), acceleration |

| Frequency Range | 0.1 Hz to 10 kHz |

| Voltage Supply | 18-30 V DC |

| Output Signals | 4-20 mA, digital status relays |

| Compatibility | Bentley Nevada 3500 Machinery Protection System |

| Mounting | 3500 Series 19-inch rack |

3. Advantages and Features

- Precision Monitoring: High-resolution ADC (16-bit) for detailed vibration analysis.

- Robust Design: EMI/EMC shielding and industrial-grade components for reliable operation in extreme temperatures (-40°C to +70°C).

- Flexible Configuration: User-configurable filters (low-pass, high-pass, band-pass) to adapt to specific machinery requirements.

- Cost-Effective Upgrade: Replaces older modules like the 85515-01 without system rework.

- Case Study: A power plant reduced maintenance costs by 25% by deploying 85515-02 to monitor steam turbine vibrations, detecting bearing wear before failure.

4. Application Areas and Use Cases

- Industries: Power generation, oil & gas, manufacturing, and aerospace.

- Applications:

- Rotor dynamics analysis.

- Bearing and gearbox health assessment.

- Condition-based maintenance systems.

- Case Example: A chemical plant used 85515-02 modules to monitor reciprocating compressors, identifying misalignment issues and avoiding a potential $500,000 production loss.

5. Competitive Comparison

Compared to similar vibration modules, the 85515-02 offers:

- Native Integration: Optimized for Bentley Nevada’s 3500 Series, ensuring plug-and-play compatibility.

- Advanced Diagnostics: Built-in waveform capture and FFT analysis for root-cause failure analysis.

- Longevity: Field-proven design with a mean time between failures (MTBF) exceeding 100,000 hours.

6. Selection Recommendations

- System Compatibility: Verify rack slot availability and sensor type compatibility.

- Environmental Factors: Consider temperature ranges and EMI exposure in the installation location.

- Scalability: Pair with additional modules (e.g., 85515-03) for multi-channel monitoring.

7. Precautions

- Installation: Follow proper grounding procedures to prevent signal interference.

- Calibration: Perform annual calibration using Bentley Nevada-approved tools.

- Software Updates: Regularly update firmware to access new features and bug fixes.

山西鑫业达国际贸易有限公司 is your trusted partner for BENTLEY NEVADA 85515-02 and other automation spare parts. Visit www.xydcontrol.com or contact us for sales and technical support.