Description

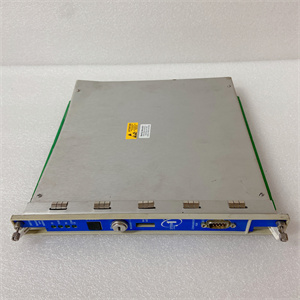

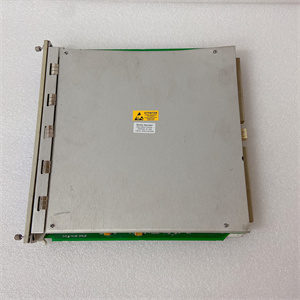

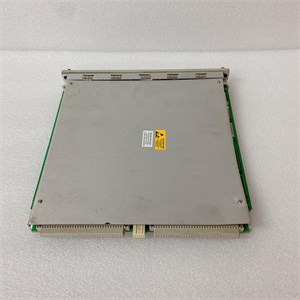

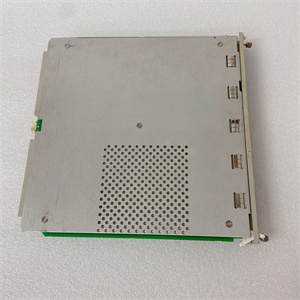

BENTLEY NEVADA 3500/22M 138607-01 Transient Data Interface Module

The BENTLEY NEVADA 3500/22M 138607-01 is a critical component of the 3500 Machinery Protection System, designed to bridge the gap between industrial monitoring hardware and advanced software platforms like System 1 Condition Monitoring and 3500 System Configuration Software. This module integrates data collection, communication, and interface functions, enabling real-time analysis of machinery health in applications such as turbines, compressors, and pumps.

1. Product Description

The 3500/22M 138607-01 serves as a Transient Data Interface (TDI), combining the roles of a Rack Interface Module (RIM) and a communication processor. It resides in Slot 1 of the 3500 rack, adjacent to power supplies, and continuously captures steady-state and transient dynamic data from M Series Monitors (e.g., 3500/40M, 3500/42M). With Ethernet (10Base-T/100Base-TX) or fiber-optic connectivity, it transmits data to host systems for predictive maintenance and system optimization.

2. Key Technical Parameters

| Parameter | Specification |

|---|---|

| Function | Transient data interface and rack communication |

| Input Compatibility | M Series Monitors (3500/40M, 3500/42M, etc.) |

| Communication Protocols | Ethernet (10Base-T/100Base-TX) or 100Base-FX fiber optic |

| Power Supply | 18–30 V DC |

| Data Capture | Static data (standard); dynamic data (optional with channel enabling disk) |

| Physical Dimensions | 241.3 mm × 24.4 mm × 241.8 mm (9.50 × 0.96 × 9.52 inches) |

| Weight | 0.91 kg (2.0 lbs) |

3. Advantages and Features

- Dual Functionality: Combines RIM and communication processor roles for simplified system architecture.

- Flexible Connectivity: Supports both copper and fiber-optic Ethernet for secure data transmission.

- Reliable Performance: MTBF exceeding 100,000 hours and operation in harsh environments (-30°C to +65°C).

- Enhanced Diagnostics: LED indicators and rack reset button for quick troubleshooting.

- Scalability: Works with all 3500 Series racks and modules, ensuring backward compatibility.

4. Application Areas and Use Cases

- Industries: Power generation, oil & gas, manufacturing, and water treatment.

- Applications:

- Real-time vibration and temperature monitoring.

- Transient waveform analysis for machinery fault detection.

- Integration with digital twin systems for predictive maintenance.

- Case Example: A power plant reduced unplanned downtime by 25% by deploying 3500/22M 138607-01 to monitor turbine vibrations, detecting rotor imbalance issues before catastrophic failure.

5. Competitive Comparison

Compared to similar modules, the 3500/22M 138607-01 offers:

- Native System Integration: Optimized for Bentley Nevada’s 3500 Series ecosystem.

- High-Speed Data Transfer: Auto-sensing Ethernet for seamless network integration.

- Extended Warranty: 1-year standard coverage with optional extended plans.

6. Selection Recommendations

- System Compatibility: Ensure compatibility with existing 3500 Series racks and M Series Monitors.

- Communication Needs: Choose Ethernet (copper or fiber) based on cabling infrastructure.

- Data Requirements: Opt for the optional channel enabling disk if dynamic data capture is needed.

7. Precautions

- Installation: Always power down the system before installing/removing the module.

- Network Security: Secure Ethernet connections to prevent unauthorized access.

- Firmware Updates: Regularly update firmware to access new features and bug fixes.

山西鑫业达国际贸易有限公司 is your trusted partner for BENTLEY NEVADA 3500/22M 138607-01 and other automation spare parts. Visit www.xydcontrol.com or contact us for sales and technical support.