Description

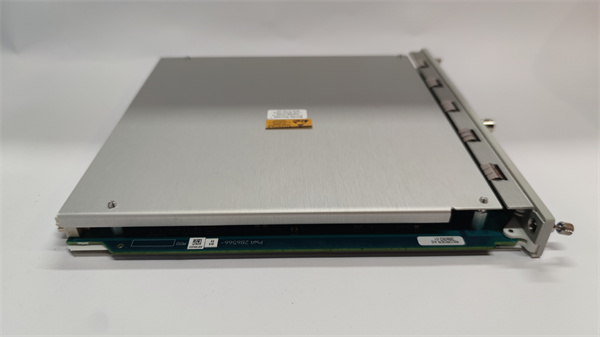

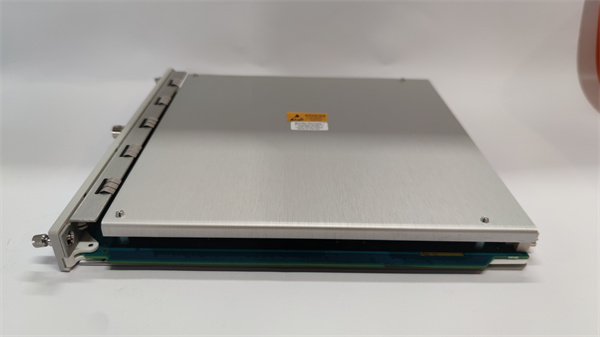

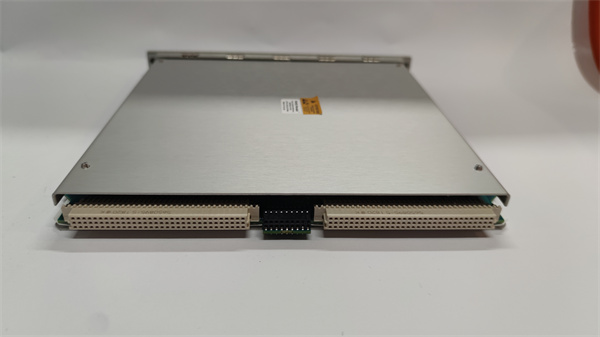

BENTLEY NEVADA 3500/54-03-00 Eddy Current Proximitor Module

1. Product Description

The BENTLEY NEVADA 3500/54-03-00 is an Eddy Current Proximitor Module designed for vibration and displacement monitoring in rotating machinery such as turbines, compressors, and pumps. As part of the 3500 Series Machinery Protection System, it converts raw sensor signals into actionable data for condition-based maintenance, ensuring optimal equipment performance and safety. With dual-channel input support, wide temperature tolerance, and compliance with API 670 standards, this module is ideal for harsh industrial environments in oil & gas, power generation, and manufacturing.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Model | 3500/54-03-00 |

| Channels | 2 channels |

| Input Type | Eddy current proximity sensors (e.g., 3300XL series) |

| Output Signal | 4–20 mA analog, digital relays (2-out-of-2 voting) |

| Power Supply | 24 Vdc ±10% |

| Measurement Range | 0–500 μm (adjustable) |

| Accuracy | ±0.1% of full scale |

| Frequency Response | 0–10 kHz |

| Temperature Range | -40°C to +70°C (operating) |

| Weight | 0.3 kg |

3. Advantages and Features

- Dual-Channel Redundancy: Ensures continuous monitoring even if one channel fails, reducing downtime risks.

- Wide Compatibility: Works with BENTLEY’s 3300XL sensors and third-party eddy current probes.

- High Precision: ±0.1% accuracy for reliable detection of rotor misalignment and bearing wear.

- Rugged Design: Operates in extreme temperatures and high-vibration environments.

- API Compliance: Meets API 670 standards for safety-critical machinery protection.

4. Application Areas and Case Studies

- Oil & Gas: Monitoring axial displacement in offshore platform compressors.

- Power Generation: Tracking turbine rotor vibration in thermal power plants.

- Manufacturing: Ensuring alignment of conveyor rollers in steel mills.

Case Study: A U.S. petrochemical plant reduced unplanned shutdowns by 20% using the 3500/54-03-00 to detect bearing damage in centrifugal pumps, enabling proactive repairs.

5. Competitor Comparison

The 3500/54-03-00 outperforms comparable modules by:

- Offering dual-channel redundancy (vs. single-channel alternatives).

- Supporting a wider temperature range (-40°C to +70°C vs. industry-standard -20°C to +60°C).

- Including built-in EMI/RFI shielding without additional components.

6. Selection Recommendations

- System Complexity: Choose for multi-axis systems requiring fail-safe redundancy.

- Environment: Opt for this module in high-temperature or high-humidity settings.

- Integration: Pair with BENTLEY’s 3500 Series rack for centralized data aggregation.

7. Precautions

- Sensor Calibration: Verify probe alignment (0.5–1.5 mm gap for eddy current sensors).

- Cable Management: Use shielded cables and avoid routing near high-voltage lines.

- Firmware Updates: Install the latest updates via BENTLEY’s 3500 组态软件 to enhance functionality.

山西鑫业达国际贸易有限公司 specializes in BENTLEY NEVADA 3500/54-03-00 and automation spare parts. Visit www.xydcontrol.com for sales and technical support.