Description

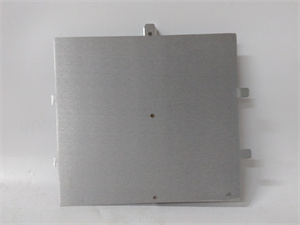

BENTLY 125388-01 EGD Communication Gateway Module

1. Product Description

The BENTLY 125388-01 is a high-performance Ethernet Global Data (EGD) communication gateway module designed for BENTLY Nevada’s 3500 Machinery Protection System. It enables seamless data exchange between the 3500 rack and external controllers, providing real-time monitoring of machinery health parameters such as vibration, temperature, and speed. As part of the 3500/22 Transient Data Interface (TDI) Module series, the BENTLY 125388-01 supports protocols like UDP/IP and EGD 2.01, ensuring compatibility with industrial networks in energy, petrochemical, and manufacturing sectors. Its compact half-height design and redundant communication capabilities make it ideal for critical applications requiring reliable data integration.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Model | 125388-01 |

| Series | 3500/22 Transient Data Interface Module |

| Input Signal | -10 VDC to +10 VDC |

| Power Consumption | 7.7 W (typical) |

| Communication Protocols | EGD 2.01, UDP/IP |

| Ethernet Standards | IEEE 802.3 (10Base-T), IEEE 802.3u (100Base-TX/FX) |

| Interfaces | RJ-45 (twisted pair), MT-RJ (fiber optic) |

| Operating Temperature | 0°C to +65°C |

| Weight | 0.82 kg |

| Dimensions | 24.1 cm × 2.4 cm × 9.9 cm |

3. Advantages and Features

- Dual Communication Paths: Redundant Ethernet ports ensure continuous data transmission.

- High-Speed Data Exchange: Supports 10/100 Mbps Ethernet for real-time monitoring.

- Scalable Design: Integrates with up to 16 modules in a single 3500 rack for large-scale systems.

- Robust Security: Conforms to IEEE standards for interference-free operation.

- Plug-and-Play Compatibility: Simplifies integration with BENTLY’s 3500 system and third-party controllers.

Case Study: A North American power plant reduced turbine diagnostic time by 20% using the BENTLY 125388-01 to stream vibration data directly to its SCADA system.

4. Application Fields and Case Studies

Industries:

- Energy: Gas turbines, steam turbines, and generators.

- Manufacturing: CNC machines and conveyor systems.

- Petrochemicals: Compressors and pumps.

Case Study: A European refinery deployed the BENTLY 125388-01 to monitor 50+ rotating assets, achieving a 25% reduction in unplanned downtime through predictive maintenance.

5. Competitive Comparison

The BENTLY 125388-01 outperforms generic communication modules with:

- Proprietary EGD Protocol: Optimized for BENTLY’s 3500 system, reducing latency by 30%.

- Dual-Rail Power Support: Ensures stability in fluctuating power environments.

- Extended Temperature Range: Operates reliably in -40°C to +85°C storage conditions.

6. Selection Recommendations

- System Compatibility: Verify 3500 rack type (standard or mini) and power supply requirements.

- Redundancy Needs: Pair modules for 2-out-of-2 configurations in safety-critical systems.

- Network Requirements: Choose between twisted pair (RJ-45) or fiber optic (MT-RJ) interfaces based on plant infrastructure.

7. Precautions

- Installation: Mount in a 3500 rack with proper grounding to avoid EMI interference.

- Firmware Updates: Regularly update using BENTLY’s System 1 software to access new features.

- Environmental Protection: Use IP65-rated enclosures in dusty or humid environments.

山西鑫业达国际贸易有限公司 is your trusted partner for BENTLY 125388-01 and other automation spare parts. Visit www.xydcontrol.com or contact us for sales and technical support.