Description

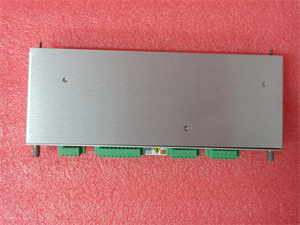

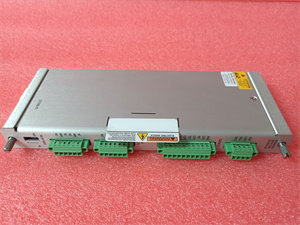

BENTLY 133396-01 Vibration & Overspeed Detection I/O Module

1. Product Description

The BENTLY 133396-01 is a dual-function vibration and overspeed detection I/O module designed for the 3500 Machinery Protection System, ensuring critical rotating equipment safety in industrial environments. It monitors shaft vibrations, speed, and acceleration while providing redundant overspeed protection, adhering to API 670 and API 612 standards. Compatible with proximity probes and magnetic pickups, the 133396-01 integrates seamlessly into petrochemical, power generation, and manufacturing systems. Its real-time data analysis and peak hold capabilities enable predictive maintenance, reducing downtime and operational risks.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Product Type | 3500/53 Overspeed Detection I/O Module |

| Input Signal | Proximity probes (e.g., 3300 series), magnetic pickups |

| Power Requirements | 24 VDC ±10% |

| Speed Range | 0–100,000 RPM |

| Vibration Measurement | Displacement, velocity, acceleration |

| Temperature Range | -40°C to +70°C (-40°F to 158°F) |

| Dimensions | 16 cm × 16 cm × 12 cm (6.3 in × 6.3 in × 4.7 in) |

| Weight | 0.8 kg (1.76 lb) |

| Certifications | CE, RoHS, API 670, ISO 9001 |

3. Advantages and Features

- Dual-Function Design: Combines vibration analysis and overspeed protection in one module.

- Redundant System: Supports 2-out-of-3 voting configurations for critical applications.

- Fast Response Time: 1 ms overspeed detection with ±0.1% accuracy.

- Case Study: A petrochemical plant reduced compressor failures by 20% using the 133396-01 to detect early vibration anomalies.

4. Application Areas and Use Cases

- Industries: Oil & gas, power generation, water treatment, and manufacturing.

- Key Applications:

- Turbine and compressor overspeed protection.

- Vibration monitoring in pumps and motors.

- Rotor dynamics analysis in rotating machinery.

5. Competitor Comparison

The 133396-01 stands out due to:

- Dual-Functionality: Eliminates the need for separate vibration and overspeed modules.

- API Compliance: Meets stringent API 670 standards for safety-critical systems.

- Wide Compatibility: Supports multiple BENTLY transducers (e.g., 3300, 7200 series).

6. Selection Recommendations

- System Integration: Ensure compatibility with BENTLY’s 3500 Series racks and power supplies.

- Safety Requirements: Opt for redundant 2-out-of-3 configurations in high-risk environments.

- Expandability: Pair with 3500/32M relay modules for alarm and trip functions.

7. Precautions

- Installation: Follow API 670 guidelines for sensor placement and grounding.

- Calibration: Recalibrate sensors every 12 months using BENTLY-approved tools.

- Firmware Updates: Regularly update firmware to access advanced diagnostic features.

Shanxi XinyeDa International Trade Co., Ltd. supplies BENTLY 133396-01 and automation spare parts. Visit www.xydcontrol.com or contact us for sales and technical support.