Description

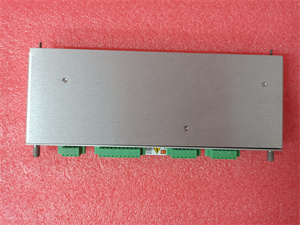

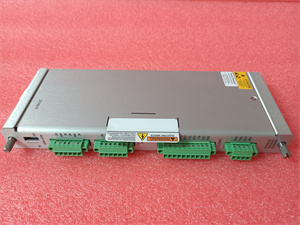

BENTLY 133396-01 Overspeed Detection I/O Module

1. Product Description

The BENTLY 133396-01 is a high-precision overspeed detection module designed for the BENTLY 3500 Machinery Protection System, ensuring reliable and rapid protection for rotating equipment in critical industrial environments. It monitors shaft speed in real time, triggers alarms, and initiates shutdowns to prevent overspeed-related failures. Rated for API 670 and API 612 compliance, the BENTLY 133396-01 supports redundant configurations (2-out-of-2 or 2-out-of-3 voting systems) and integrates seamlessly with BENTLY’s 3500 Rack system. Its compact design and wide compatibility with proximity probes and magnetic pickups make it ideal for power plants, refineries, and manufacturing facilities.

2. Key Technical Parameters

| Parameter | Specification |

|---|---|

| Input Types | Proximity probes, magnetic pickups |

| Channels | 1 channel (overspeed detection) |

| Input Signal Range | +10 V to -24 V DC (auto/manual threshold) |

| Power Consumption | 8.0 W (typical) |

| Temperature Range | -30°C to +65°C |

| Transducer Compatibility | BENTLY 3300/7200 series proximity probes |

| Certifications | API 670, API 612 |

| Dimensions | 16 cm × 16 cm × 12 cm |

| Weight | 0.45 kg |

3. Advantages and Features

- Redundant Protection: Supports 2-out-of-3 voting systems for enhanced safety.

- Fast Response Time: Detects overspeed within milliseconds to prevent catastrophic failures.

- Wide Sensor Compatibility: Works with multiple BENTLY probe types, reducing integration complexity.

- LED Status Indicators: Real-time health monitoring via front-panel LEDs (OK, TX/XR, Alarm).

- Epoxy Sealing: Ensures resistance to dust, moisture, and vibrations in harsh environments.

4. Application Areas and Case Studies

Industries:

- Petrochemicals

- Power generation

- Aerospace

- Heavy machinery manufacturing

Case Study:

A Middle Eastern refinery implemented the BENTLY 133396-01 to protect centrifugal compressors. The module detected a 12% speed surge during startup, triggering an immediate shutdown and avoiding a $1.5 million loss in production downtime.

A Middle Eastern refinery implemented the BENTLY 133396-01 to protect centrifugal compressors. The module detected a 12% speed surge during startup, triggering an immediate shutdown and avoiding a $1.5 million loss in production downtime.

5. Competitive Comparison

The BENTLY 133396-01 outperforms generic overspeed modules with its API-rated redundancy and direct integration with BENTLY’s 3500 Rack system. Unlike standalone solutions, it leverages BENTLY’s proven vibration and speed monitoring algorithms, reducing calibration efforts and improving accuracy. Its wide temperature range and epoxy-sealed design also offer better durability than competing models.

6. Selection Recommendations

- System Redundancy: Opt for a 2-out-of-3 configuration for critical machinery.

- Sensor Type: Ensure compatibility with your existing proximity probes or magnetic pickups.

- Power Requirements: Verify 3500 Rack power supply capacity for multiple modules.

7. Installation and Usage Notes

- Static Protection: Handle the module with anti-static gear to avoid component damage.

- Calibration: Use BENTLY’s TK3 Probe Checker for sensor alignment.

- Bypass Mode: Avoid prolonged use to maintain safety integrity.

山西鑫业达国际贸易有限公司 is your trusted partner for BENTLY 133396-01 and other automation spare parts. Visit our website www.xydcontrol.com or contact us for sales and technical support.