Description

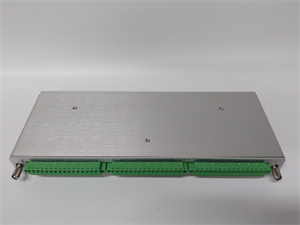

BENTLY 133819-01 Vibration Monitoring Module

1. Product Description

The BENTLY 133819-01 is a high-performance vibration monitoring module designed for the 3500 Machinery Protection System, delivering real-time analysis of machinery vibration levels to enable predictive maintenance and prevent unexpected downtime. Compatible with BENTLY’s proximity sensors and accelerometers, it supports dual-channel monitoring of critical parameters like velocity, displacement, and acceleration. Built with robust materials and explosion-proof certifications (e.g., ATEX, FM), the 133819-01 operates reliably in harsh industrial environments, ensuring continuous data accuracy for process optimization and safety.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Product Type | 3500/60 Vibration Monitor Module (Dual-channel) |

| Input Signal | Proximity probes, accelerometers, velocity sensors |

| Power Requirements | 220 VAC ±10% |

| Output Frequency | 30 kHz (analog) / 50 kHz (digital) |

| Temperature Range | -40°C to +70°C (-40°F to 158°F) |

| Dimensions | 24.1 cm × 2.4 cm × 9.9 cm (9.5 in × 0.94 in × 3.9 in) |

| Weight | 0.82 kg (1.8 lb) |

| Certifications | CE, RoHS, API 670, ATEX, FM, DNV |

3. Advantages and Features

- Dual-Channel Precision: Simultaneously monitors two vibration parameters with ±0.1% accuracy.

- Hazardous Environment Compliance: ATEX and FM certifications ensure safe operation in explosive zones.

- Hot-Swap Technology: Enables module replacement without system shutdown, minimizing downtime.

- Case Study: A petrochemical plant reduced maintenance costs by 20% using the 133819-01 to detect early-stage bearing failures in compressors.

4. Application Areas and Use Cases

- Industries: Power generation, oil & gas, petrochemical, manufacturing.

- Key Applications:

- Vibration analysis of turbines, pumps, and motors.

- Condition-based maintenance in rotating machinery.

- Early fault detection in critical infrastructure.

5. Competitor Comparison

The 133819-01 outperforms alternatives with:

- Wider Sensor Compatibility: Supports proximity probes, accelerometers, and velocity sensors.

- Enhanced Safety: Multiple explosion-proof certifications for Zone 0/1/2.

- Higher Frequency Output: 50 kHz digital output for detailed vibration pattern analysis.

6. Selection Recommendations

- System Integration: Ensure compatibility with existing 3500 Series racks and BENTLY sensors.

- Environment: Verify temperature and hazardous area ratings match site conditions.

- Scalability: Choose dual-channel modules for multi-parameter monitoring in large-scale systems.

7. Precautions

- Sensor Calibration: Use BENTLY-approved sensors and recalibrate every 12 months.

- Installation: Follow API 670 guidelines for wiring and grounding to avoid signal interference.

- Firmware Updates: Regularly update firmware to access the latest diagnostic features.

Shanxi XinyeDa International Trade Co., Ltd. supplies BENTLY 133819-01 and automation spare parts. Visit www.xydcontrol.com or contact us for sales and technical support.