Description

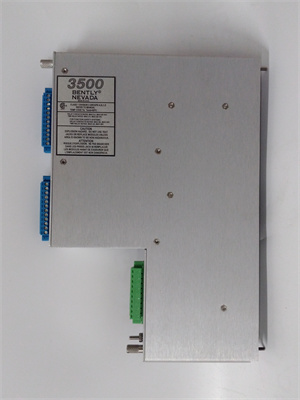

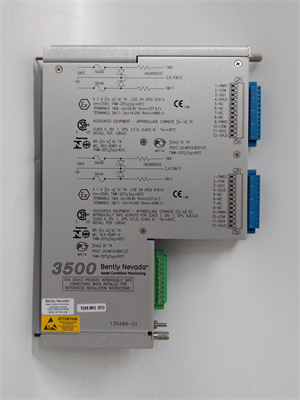

BENTLY NEVADA 135489-01 I/O Module with Internal Barriers

1. Product Description

The BENTLY NEVADA 135489-01 is a high-performance 4-channel I/O module designed for the 3500 Machinery Protection System, offering intrinsic safety and explosion protection for critical industrial applications. It serves as an interface for transducer systems, ensuring reliable vibration monitoring and machinery health assessment in hazardous environments such as oil refineries, power plants, and chemical processing facilities. The module integrates seamlessly with BENTLY’s 3500 series, providing real-time data to prevent equipment failures and optimize operational efficiency.

The BENTLY NEVADA 135489-01 is a high-performance 4-channel I/O module designed for the 3500 Machinery Protection System, offering intrinsic safety and explosion protection for critical industrial applications. It serves as an interface for transducer systems, ensuring reliable vibration monitoring and machinery health assessment in hazardous environments such as oil refineries, power plants, and chemical processing facilities. The module integrates seamlessly with BENTLY’s 3500 series, providing real-time data to prevent equipment failures and optimize operational efficiency.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 135489-01 |

| Function | 4-channel internal barrier I/O module |

| Compatibility | BENTLY 3500 Machinery Protection System |

| Voltage Range | Power: 26.25 V (circuit), Signal: 13.65 V |

| Channel Type | Proximity/Acceleration (4 channels) |

| Temperature Range | -30°C to +65°C (standard), 0°C to +65°C (internal barrier) |

| Dimensions | 241.3 mm x 24.4 mm x 163.1 mm (9.50 in x 0.96 in x 6.42 in) |

| Weight | 0.46 kg (1.01 lb) |

| Certifications | CE, RoHS, Explosion-proof standards |

BENTLY 135489-01

3. Advantages and Features

- Intrinsic Safety: Eliminates the need for external barriers, reducing installation complexity and costs while complying with explosion-proof requirements.

- Precision Monitoring: Supports high-frequency vibration analysis (up to 30 kHz) with ±1% amplitude accuracy for early fault detection.

- Reliable Performance: Robust design ensures signal integrity in extreme conditions, minimizing downtime and maintenance.

- Flexible Integration: Coexists with standard 3500 modules in the same rack, enabling easy system upgrades.

4. Application Areas and Use Cases

Industry Applications:

Industry Applications:

- Oil & Gas: Monitoring compressors and pumps in offshore platforms.

- Power Generation: Protecting steam turbines and generators.

- Manufacturing: Ensuring stable operation of rotating machinery.

Case Study: A petrochemical plant in Texas integrated the 135489-01 to monitor reactor pumps. By detecting early signs of bearing wear through real-time vibration data, the plant reduced unplanned shutdowns by 40% over a year.

5. Competitor Comparison

- Simplified Installation: Internal barriers eliminate external components, streamlining setup compared to systems requiring separate safety interfaces.

- Enhanced Compatibility: Directly compatible with BENTLY’s 3500 system, avoiding compatibility issues common with third-party modules.

- Cost Efficiency: Reduces certification efforts by meeting safety standards inherently, unlike generic modules needing additional approvals.

BENTLY 135489-01

6. Selection Recommendations

- System Compatibility: Verify compatibility with your existing 3500 rack configuration.

- Environment: Choose internal barrier modules for hazardous areas; standard modules for non-explosive environments.

- Scalability: Opt for 4-channel modules for mid-sized systems or upgrade to higher-channel variants as needed.

7. Precautions

- Installation: Avoid blocking fire sprinkler systems or electrical conduits during module placement.

- Calibration: Re-calibrate sensors after module replacement to maintain accuracy.

- Safety Compliance: Ensure compliance with local explosion-proof regulations and OSHA standards.

山西鑫业达国际贸易有限公司 offers BENTLY NEVADA 135489-01 and comprehensive automation solutions. Visit www.xydcontrol.com for technical support and product inquiries.