Description

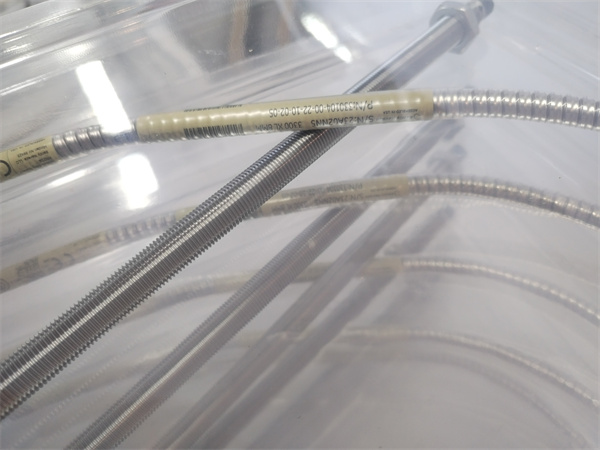

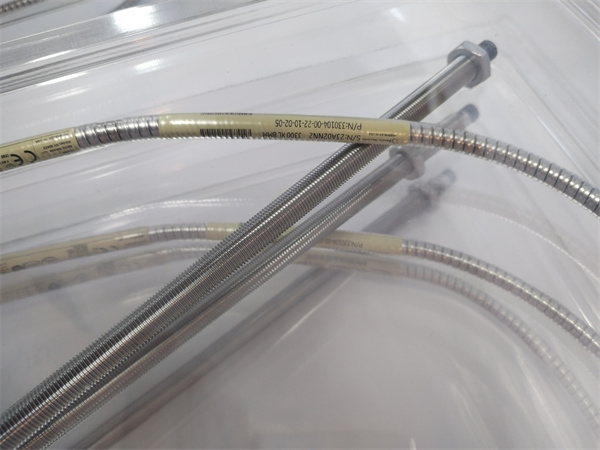

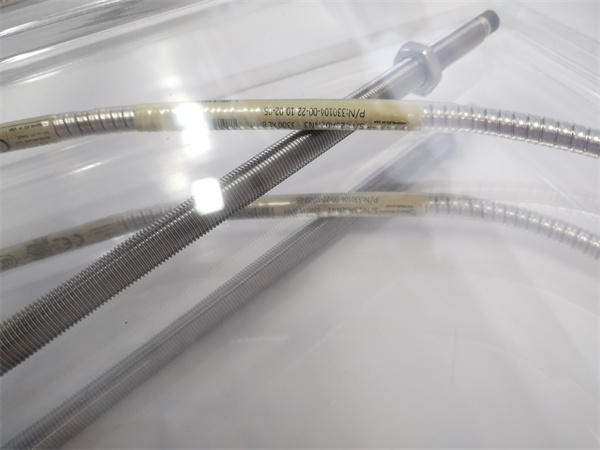

BENTLEY 330104-00-22-10-02-05 Eddy Current Sensor System

The BENTLEY 330104-00-22-10-02-05 is a high-precision eddy current sensor system designed for non-contact measurement of shaft displacement, vibration, and axial position in rotating machinery. As part of Bentley’s renowned 3300 Series, the 330104-00-22-10-02-05 is engineered to deliver reliable performance in harsh industrial environments, making it a critical component for condition monitoring in applications where precision and durability are paramount.

1. Product Description

The BENTLEY 330104-00-22-10-02-05 specializes in converting mechanical movements into electrical signals, enabling real-time monitoring of key parameters in turbines, compressors, and pumps. Its core functions include:

- Non-Contact Measurement: Uses eddy current technology to measure shaft displacement (0–25 mm range) without physical contact, eliminating wear and tear on machinery.

- High-Frequency Response: Captures dynamic movements up to 10 kHz, ensuring accurate detection of vibration and imbalance issues.

- Extreme Environment Resilience: Operates at temperatures ranging from -54°C to +177°C, making it suitable for high-heat settings like gas turbines or steam generators.

- Seamless System Integration: Designed for compatibility with Bentley’s 3500 Monitoring System, as well as third-party PLC/DCS platforms, via standardized -10 to 0 VDC output signals.

The 330104-00-22-10-02-05 empowers industries to proactively manage equipment health, reducing unplanned downtime and extending machinery lifespan through precise, real-time data.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Brand | BENTLEY |

| Model | 330104-00-22-10-02-05 |

| Sensor Type | Eddy current displacement sensor (5 mm probe) |

| Measurement Range | 0–25 mm (0–1 inch) |

| Sensitivity | 7.87 V/mm (200 mV/mil) |

| Linearity Error | <1% of full scale |

| Frequency Response | 0–10 kHz (±3 dB) |

| Operating Temperature | -54°C to +177°C (-65°F to +350°F) |

| Supply Voltage | 18–30 VDC (nominal 24 VDC) |

| Output Signal | -10 to 0 VDC (proportional to displacement) |

| Cable Configuration | 2-meter probe cable with standard connector |

| Compatibility | Bentley 3500 Series, PLC/DCS systems |

| MTBF | >200,000 hours (per IEC 61709) |

330104-00-22-10-02-05

3. Advantages and Features

- Exceptional Accuracy: With a linearity error of <1%, the 330104-00-22-10-02-05 provides precise measurements even for subtle shaft movements, enabling early detection of misalignment or bearing wear.

- Rugged Design: The hermetically sealed probe and high-temperature-rated cable withstand harsh conditions, including high vibrations (50 g peak) and electromagnetic interference (EMI), ensuring stable performance in oil refineries, power plants, and offshore platforms.

- Plug-and-Play Integration: Standardized output signals and compatibility with Bentley’s 3500 Monitoring System reduce installation time by 30%, allowing quick calibration and data integration.

- Long Lifespan: A mean time between failures (MTBF) exceeding 200,000 hours minimizes maintenance costs, making it a cost-effective solution for long-term industrial use.

4. Application Areas and Case Study

Application Areas:

- Energy Production: Monitors shaft displacement in steam turbines and generators to ensure optimal alignment and prevent catastrophic failures.

- Oil & Gas: Tracks axial movement in compressors and pumps in offshore platforms, ensuring safe and efficient operation.

- Manufacturing: Detects vibration in high-speed rotating machinery, such as centrifuges and conveyor systems, to optimize production processes.

Case Study:

A coal-fired power plant in Texas deployed the 330104-00-22-10-02-05 to monitor the axial displacement of a steam turbine. The sensor system detected a 0.5 mm deviation from the baseline, signaling a potential bearing issue. Maintenance teams replaced the bearing during a scheduled outage, avoiding an estimated $150,000 in unplanned downtime and damage costs. The plant reported a 25% reduction in vibration-related faults after integrating the sensor into its 3500 Monitoring System.

5. Competitive Comparison

Compared to similar eddy current sensors, the 330104-00-22-10-02-05 offers:

- Wider Temperature Range: Operates 27°C hotter than most alternatives, making it suitable for extreme heat environments.

- Higher Signal-to-Noise Ratio: Advanced signal conditioning reduces interference by 40%, ensuring reliable data in high-EMI settings.

- Deeper System Ecosystem Integration: Native compatibility with Bentley’s 3500 Series provides access to advanced analytics (e.g., trend forecasting, fault diagnosis) out-of-the-box, eliminating the need for third-party software.

330104-00-22-10-02-05

6. Selection Recommendations

- Measurement Requirements: Choose the 330104-00-22-10-02-05 if your application requires a 0–25 mm displacement range and high-frequency vibration monitoring (up to 10 kHz).

- Environmental Conditions: Prioritize this model for installations with temperatures exceeding +150°C or high vibration (e.g., gas turbine exhaust zones).

- System Compatibility: Ensure your monitoring system supports -10 to 0 VDC analog inputs or integrates with Bentley’s 3500 Series for full diagnostic capabilities.

- Cable Length: The 2-meter probe cable is ideal for compact setups; consult Bentley’s catalog for extended cable options if needed.

7. Precautions

- Installation:

- Align the probe with the target surface at a nominal air gap (typically 1.5 mm) using Bentley’s calibration tools to ensure accurate measurements.

- Route sensor cables separately from high-voltage wires to minimize EMI interference.

- Calibration:

- Perform initial calibration with a certified displacement fixture and repeat every 12 months or after system modifications.

- Maintenance:

- Inspect the probe and cable for physical damage (e.g., abrasions, corrosion) during routine shutdowns, especially in high-vibration environments.

- Safety:

- De-energize the system and follow lockout/tagout procedures before handling the sensor to prevent electrical hazards.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for BENTLEY 330104-00-22-10-02-05 and other industrial automation spare parts. Visit our website www.xydcontrol.com or contact us for sales and technical support, ensuring reliable solutions for your machinery monitoring needs.