Description

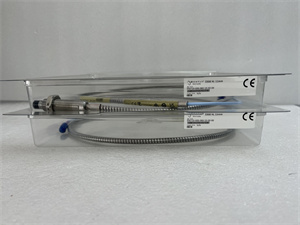

BENTLY 330710-000-60-10-02-00 Extension Cable for 3300 Series Proximity Probes

The BENTLY 330710-000-60-10-02-00 is a high-reliability extension cable designed for use with Bentley’s 3300 Series proximity probes, enabling seamless signal transmission in industrial machinery condition monitoring systems. Engineered to bridge the gap between proximity probes and monitoring modules, the 330710-000-60-10-02-00 ensures stable connectivity and signal integrity in harsh environments, making it a critical component for accurate measurement of shaft displacement, vibration, and axial position in rotating equipment.

1. Product Description

The BENTLY 330710-000-60-10-02-00 serves as a vital link in machinery monitoring setups, extending the reach of proximity probes (e.g., 330104, 330703) to the 3500 Monitoring System while preserving signal quality. Its core functions include:

- Signal Transmission: Carries low-voltage analog signals (-20 to 0 VDC) from probes to modules with minimal interference, supporting precise displacement and vibration measurements over long distances.

- Environmental Resilience: Constructed with high-temperature-resistant FEP insulation and stainless-steel connectors, operating reliably in temperatures ranging from -51°C to +260°C (-60°F to +500°F), ideal for extreme industrial environments.

- Modular Compatibility: Designed for direct compatibility with Bentley’s 3300 Series probes and 3500 Series racks, featuring a 90° ClickLoc® connector for easy installation in space-constrained areas.

- EMI Shielding: Dual-layer braided stainless-steel shielding reduces electromagnetic interference (EMI) by 90%, ensuring stable signal transmission in high-noise environments.

The 330710-000-60-10-02-00 simplifies system installation with its plug-and-play design, reducing setup time and minimizing risks of signal loss, making it an essential component for predictive maintenance in critical machinery.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Brand | BENTLEY |

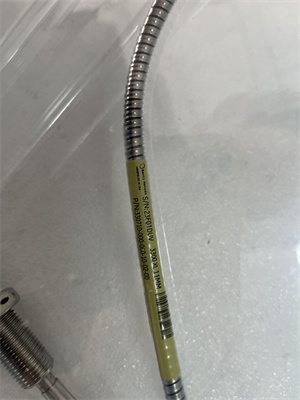

| Model | 330710-000-60-10-02-00 |

| Cable Type | Coaxial extension cable for proximity probes |

| Length | 60 feet (18.3 meters) |

| Connector Type | 90° ClickLoc® miniature coaxial connector (male/female) |

| Conductor Material | Tinned copper with FEP insulation |

| Shielding | Double-layer braided stainless-steel |

| Operating Temperature | -51°C to +260°C (-60°F to +500°F) |

| Flexural Life | >10 million flex cycles at 23°C |

| Compatibility | Bentley 3300 Series proximity probes (8 mm, 11 mm, 16 mm) and 3500 Monitoring System |

| Certifications | CE, UL, ATEX Zone 2 (for hazardous environments) |

BENTLY 330710-000-60-10-02-00

3. Advantages and Features

- Long-Distance Signal Stability:

- Maintains signal integrity over 18.3 meters with less than 0.5% attenuation, ensuring accurate measurements even in large industrial setups.

- Advanced impedance matching (50Ω) reduces signal distortion, critical for high-frequency vibration analysis (up to 10 kHz).

- Rugged Design for Harsh Environments:

- FEP insulation resists chemicals, oils, and moisture, making it suitable for petrochemical plants and offshore platforms.

- Stainless-steel connectors withstand 330N (75 lbf) tensile force, preventing cable detachment in high-vibration environments.

- Installation Efficiency:

- 90° connector design allows routing in tight spaces (e.g., around machinery flanges), reducing installation time by 30% compared to straight connectors.

- Tool-free ClickLoc® mechanism enables quick attachment and removal, simplifying maintenance and sensor replacement.

4. Application Areas and Case Study

Application Areas:

- Oil & Gas: Connects proximity probes to monitoring systems in compressors, pumps, and turbines in refineries and offshore rigs.

- Power Generation: Used in steam turbines and generators to extend probe reach in power plant layouts with complex machinery arrangements.

- Manufacturing: Supports vibration monitoring in high-speed rotating equipment like centrifuges and conveyor systems in automotive and aerospace production lines.

Case Study:

A petrochemical plant in the Middle East utilized the 330710-000-60-10-02-00 to connect 8 mm proximity probes to a 3500 Monitoring System for a gas compressor train. The cable’s 90° connectors allowed installation in a confined space near the compressor casing, while its high-temperature rating ensured reliable signal transmission in the +200°C environment. The system detected a 0.3 mm shaft displacement anomaly, enabling proactive maintenance and avoiding a potential $150,000 downtime cost.

5. Competitive Comparison

Compared to similar extension cables, the 330710-000-60-10-02-00 offers:

- Wider Temperature Range: Operates 40°C hotter than many alternatives, making it suitable for extreme heat applications without signal degradation.

- Superior EMI Protection: Dual shielding provides 20% better noise reduction in high-EMI environments, such as those with frequent motor startups or welding operations.

- Space-Saving Design: 90° connectors reduce installation depth by 50%, ideal for machinery with limited access points, a common challenge in retrofitted industrial setups.

BENTLY 330710-000-60-10-02-00

6. Selection Recommendations

- Length Requirements: Choose the 60-foot (18.3-meter) 330710-000-60-10-02-00 for large machinery layouts; consider shorter lengths (e.g., 30 feet) for compact setups.

- Environmental Conditions: Prioritize this model for installations with temperatures exceeding +150°C or exposure to corrosive substances, where FEP insulation and stainless-steel shielding are essential.

- System Compatibility: Ensure compatibility with your probe type (8 mm, 11 mm, or 16 mm) and monitoring system (Bentley 3500 Series or compatible DCS/PLC platforms).

- Connector Orientation: Opt for the 90° connector if routing cables in tight spaces; straight connectors are available in other models for linear installations.

7. Precautions

- Installation:

- Route cables at least 30 cm away from high-voltage or high-frequency cables to minimize EMI interference.

- Tighten connectors to 1.5 N·m torque using a calibrated tool to ensure secure, low-resistance connections.

- Maintenance:

- Inspect cable insulation and connectors quarterly for signs of wear, especially at bends and termination points.

- Verify signal integrity annually using a Bentley 3500/40M Proximitor Monitor to ensure linearity and noise levels meet specifications.

- Safety:

- De-energize the system and follow lockout/tagout procedures before handling the cable to prevent electrical hazards.

- In hazardous environments, confirm ATEX certification compliance and use appropriate conduit for cable protection.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for BENTLY 330710-000-60-10-02-00 and other industrial automation spare parts. Visit our website www.xydcontrol.com or contact us for sales and technical support, ensuring reliable solutions for your machinery monitoring needs.