Description

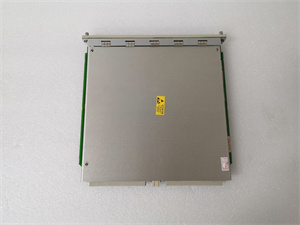

BENTLY 3500/22M 138607-01 Transient Data Interface (TDI) Module

1. Product Description

The BENTLY 3500/22M 138607-01 is a high-performance transient data interface module designed for the 3500 Series Machinery Protection System, enabling real-time monitoring and analysis of rotating equipment health. It bridges the 3500 rack with advanced software like System 1 Condition Monitoring Software, capturing both steady-state and transient waveform data for predictive maintenance. This module combines the roles of a 3500/20 Rack Interface Module (RIM) and a communication processor, supporting Ethernet (10/100BASE-TX) and optional fiber-optic connectivity for reliable data transmission in harsh industrial environments.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Input Signal Range | -10 V DC to +10 V DC |

| Power Supply | 24 V DC (dual redundancy optional) |

| Power Consumption | 10.5 W |

| Ethernet Compatibility | 10BASE-T/100BASE-TX (auto-sensing) |

| USB Interface | USB-B for configuration and diagnostics |

| Data Storage | 16 MB for transient data |

| Operating Temperature | -30°C to +65°C (-22°F to 149°F) |

| Mounting | 3500 Series rack (slot 1 adjacent to power supply) |

3. Advantages and Features

- Integrated Functionality: Combines RIM and communication processor roles, reducing system complexity and costs.

- High-Speed Data Capture: Millisecond precision for transient waveforms, enabling early fault detection.

- Flexible Connectivity: Supports copper or fiber-optic Ethernet for EMI-resistant long-distance data transfer.

- Rugged Design: IP67-rated housing withstands dust, moisture, and extreme temperatures.

- Case Study: A U.S. refinery used the 3500/22M 138607-01 to monitor compressor vibrations. Real-time transient analysis detected bearing wear, preventing a $200,000 breakdown and reducing downtime by 30%.

4. Application Areas and Use Cases

- Industries: Power generation (turbines), oil and gas (compressors), manufacturing (rotating machinery).

- Key Applications:

- Vibration analysis and fault detection.

- Real-time health monitoring of critical machinery.

- Predictive maintenance to avoid costly downtime.

5. Competitor Comparison

The 3500/22M 138607-01 outperforms standard modules with:

- Dual Functionality: Integrates RIM and communication processor in a single unit.

- Higher Data Resolution: Supports up to 20 kHz transient recording for detailed waveform analysis.

- Ethernet Redundancy: Dual ports ensure continuous data flow in mission-critical applications.

6. Selection Recommendations

- Functionality: Choose this module for transient data analysis and Ethernet connectivity.

- Environment: Opt for fiber-optic variants (e.g., 288055-02) in EMI-sensitive environments.

- Compatibility: Ensure alignment with 3500 Series racks and System 1 software.

7. Precautions

- Installation: Mount in slot 1 of the 3500 rack and secure proper grounding.

- Firmware Updates: Regularly update via 3500 Configuration Software for optimal performance.

- Safety: Disconnect power before module replacement to avoid electrical hazards.

Shanxi XinyeDa International Trade Co., Ltd. provides BENTLY 3500/22M 138607-01 modules and automation solutions. Visit www.xydcontrol.com or contact us for sales, technical support, and customized machinery monitoring systems.