Description

1. Product Description

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | Speed and Keyphasor Monitoring Module |

| Input Channels | 1 channel for speed/keyphasor input |

| Sensor Compatibility | Magnetic pickups, proximity probes (AC or DC coupled) |

| Frequency Range | 0.1 Hz to 50 kHz (depending on sensor type) |

| Output Signals | Analog: 4-20 mA (isolated, two-wire) Digital: Serial communication via 3500 backplane |

| Power Supply | 24 VDC ±10%, from 3500 system rack |

| Operating Temperature | -40°C to +85°C (-40°F to +185°F) |

| Communication Interface | 3500 System Data Highway (SDH) for module-to-system connectivity |

| Physical Dimensions | Standard 3500 rack-mountable size (1.25 inches wide) |

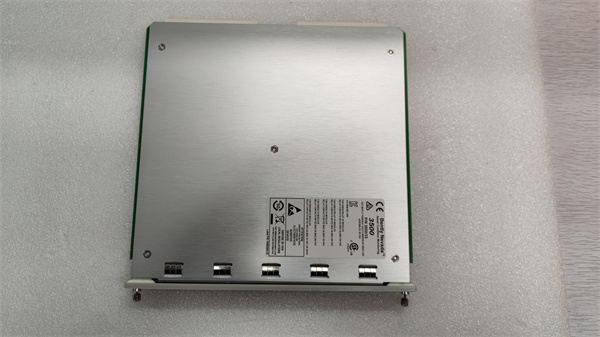

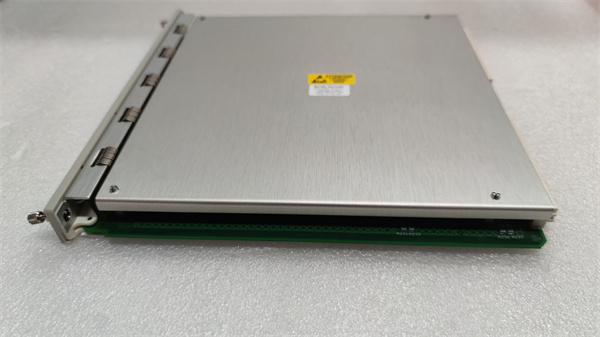

Bently 3500/33-1-00

3. Advantages and Features

4. Application Areas and Use Cases

5. Competitive Landscape Comparison

Compared to similar monitoring modules on the market, the BENTLY 3500/33-1-00 distinguishes itself through its superior noise immunity and wide temperature operating range, making it suitable for extreme industrial environments. Its deep integration with the 3500 Series platform also offers a more cohesive and scalable solution, as opposed to standalone modules that may require additional hardware or software adjustments for system-wide compatibility.

Bently 3500/33-1-00

6. Selection Recommendations

- Compatibility: Ensure your existing system uses the 3500 Series rack and backplane to leverage full functionality.

- Sensor Type: Verify that the module supports your chosen sensors (e.g., magnetic pickups vs. proximity probes) and their output characteristics.

- Environmental Conditions: If operating in extreme temperatures or high-vibration zones, confirm that the module’s specifications align with your site’s requirements.

- Scalability: Plan for future expansions by evaluating how the module integrates with other 3500 Series components for a holistic monitoring solution.

7. Usage and Installation Notes

- Installation: Mount the module in a 3500 Series rack, ensuring proper grounding to minimize EMI interference. Follow the 3500 System Installation Manual for wiring guidelines.

- Calibration: Perform initial calibration with the intended sensor to ensure accurate measurements. Regularly verify calibration during routine maintenance.

- Diagnostics: Utilize the 3500 System’s built-in diagnostics to monitor module health and detect sensor faults or communication issues promptly.

- Safety: Disconnect power before installing or servicing the module to avoid electrical hazards.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide PFEA112-65 3BSE030369R65 and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.