Description

1. Product Description

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | Speed and Keyphasor Monitor |

| Input Channels | 2 channels (speed) + 1 channel (keyphasor) |

| Sensor Compatibility | Magnetic pickup, active proximity probes |

| Frequency Range | 0.1 Hz to 12 kHz (speed), 1 Hz to 12 kHz (keyphasor) |

| Output Signals | 4-20 mA analog, digital (via 3500 system bus) |

| Voltage Supply | 24V DC ±15% |

| Operating Temperature | -40°C to +85°C |

| Dimensions | 17.78 mm (width) × 165.1 mm (height) × 233.68 mm (depth) |

| Certifications | CE, RoHS, ISO 9001 compliant |

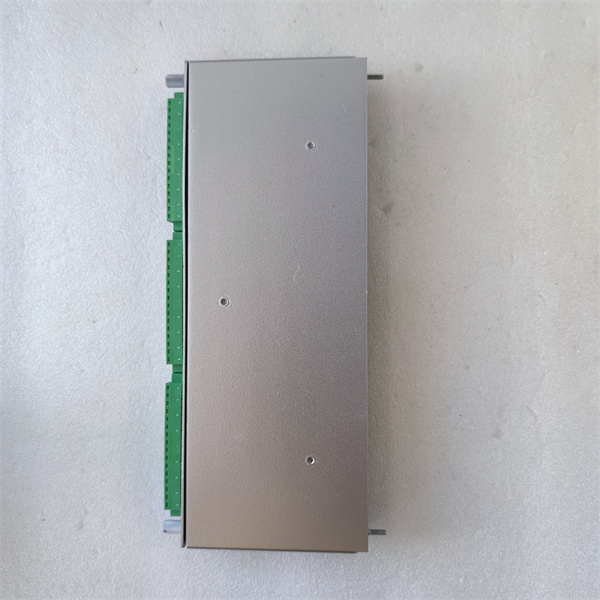

BENTLY 3500/33 149992-01

3. Advantages and Features

4. Application Areas and Case Studies

5. Competitive Comparison

Compared to similar monitoring modules, the BENTLY 3500/33 149992-01 offers superior noise immunity and measurement accuracy, particularly in high-temperature and high-vibration environments. Its robust integration with the 3500 system provides a comprehensive monitoring solution, unlike standalone modules that may require additional hardware or software adjustments. The module’s dual-channel design and advanced diagnostics also offer enhanced functionality, making it a more versatile choice for complex machinery setups where reliability and precision are non-negotiable.

BENTLY 3500/33 149992-01

6. Selection Recommendations

- System Compatibility: Ensure it is compatible with your existing 3500 framework and sensor types (e.g., magnetic pickups or active probes).

- Measurement Requirements: Confirm the frequency range and accuracy meet your machinery’s operational speed and monitoring needs.

- Environmental Conditions: Verify the module’s temperature and vibration resistance align with your site’s industrial environment.

- Redundancy Needs: Evaluate if the dual-channel design is necessary for your application to ensure continuous monitoring and system reliability.

7. Precautions

- Installation: Power down the 3500 system and follow electrostatic discharge (ESD) protocols to avoid damaging the module during installation.

- Sensor Calibration: Regularly calibrate connected sensors to maintain measurement accuracy, following the manufacturer’s guidelines.

- Maintenance: Inspect wiring connections and clean the module periodically to prevent signal interference or mechanical issues.

- Safety Compliance: Adhere to local safety standards when working with high-voltage systems or rotating machinery to ensure operator and equipment safety.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide PFEA112-65 3BSE030369R65 and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.