Description

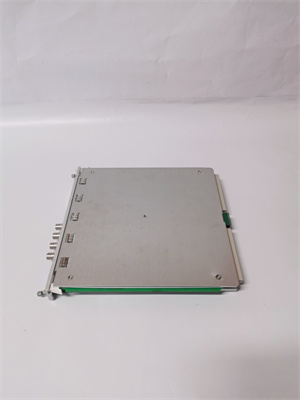

BENTLY NEVADA 3500/42M 140734-02 Proximitor Seismic Monitor

1. Product Description

The BENTLY NEVADA 3500/42M 140734-02 is a high-performance vibration monitoring module designed for critical rotating machinery in industries such as power generation, oil & gas, and manufacturing. With four channels supporting proximity and seismic transducers, this module provides real-time analysis of parameters like radial vibration, axial displacement, and acceleration. Its advanced signal conditioning and alarm-triggering capabilities enable predictive maintenance, reducing unexpected downtime and operational costs. The 3500/42M 140734-02 integrates seamlessly with BENTLY’s modular 3500 monitoring system, ensuring compatibility and ease of configuration.

The BENTLY NEVADA 3500/42M 140734-02 is a high-performance vibration monitoring module designed for critical rotating machinery in industries such as power generation, oil & gas, and manufacturing. With four channels supporting proximity and seismic transducers, this module provides real-time analysis of parameters like radial vibration, axial displacement, and acceleration. Its advanced signal conditioning and alarm-triggering capabilities enable predictive maintenance, reducing unexpected downtime and operational costs. The 3500/42M 140734-02 integrates seamlessly with BENTLY’s modular 3500 monitoring system, ensuring compatibility and ease of configuration.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 3500/42M 140734-02 |

| Channels | 4 (Proximity/Seismic inputs) |

| Input Range | -5 to +5 VDC (proximitor), 4–20 mA (seismic) |

| Operating Voltage | 24 VDC ±10% or 100–265 VAC 50/60 Hz |

| Power Consumption | ≤1.5 W (DC) / ≤2 W (AC) |

| Temperature Range | -40°C to +70°C (-40°F to +158°F) |

| Frequency Range | 0.1–10,000 Hz (proximity), 0.5–1000 Hz (seismic) |

| Output Type | Relay contacts, analog (4–20 mA), digital |

| Resolution | 0.01 Hz (frequency), 0.1% FS (vibration) |

| Accuracy | ±1% of full scale |

BENTLY 3500/42M 140734-02

3. Advantages and Features

- Multi-Parameter Monitoring: Simultaneously tracks radial vibration, thrust position, and shaft eccentricity for comprehensive machine health assessment.

- Real-Time Alarms: Compares live data against user-defined setpoints to trigger alerts or shutdowns, preventing catastrophic failures.

- Wide Environmental Tolerance: Operates in extreme temperatures and harsh conditions, ensuring reliability in offshore platforms or high-temperature plants.

- Flexible Configuration: Customizable via BENTLY’s 3500 Rack Configuration Software for channel-specific monitoring needs.

- Space-Saving Design: Fits into standard 3500 series racks, minimizing panel space requirements.

4. Application Areas and Use Cases

Industry Applications:

Industry Applications:

- Power Generation: Steam turbines, generators.

- Oil & Gas: Compressors, pumps, offshore drilling equipment.

- Manufacturing: High-speed rotating machinery.

Case Study: A North American refinery deployed the 3500/42M 140734-02 to monitor vibrations in a centrifugal compressor. Early detection of bearing wear via real-time alerts allowed scheduled maintenance, avoiding an estimated $1.2 million in repair costs and 48 hours of downtime.

5. Competitor Comparison

- Higher Channel Density: Offers 4 channels compared to 2–3 channels in similar modules.

- Extended Temperature Range: Operates at -40°C to +70°C, outperforming most competitors’ 0°C–50°C limits.

- Integrated Signal Conditioning: Reduces external hardware needs by combining proximity and seismic monitoring in a single module.

BENTLY 3500/42M 140734-02

6. Selection Recommendations

- Channel Requirements: Opt for the 3500/42M 140734-02 for 4-channel systems; consider the 3500/42M 140734-05 for 5-channel needs.

- Sensor Compatibility: Pair with BENTLY’s 3300 XL proximity probes or ICP seismic sensors for optimal accuracy.

- Environment: Ensure the module’s temperature rating matches the installation site’s conditions.

7. Precautions

- Sensor Calibration: 定期校准传感器(建议每 6 个月一次)to maintain accuracy.

- Signal Interference: Use shielded cables and proper grounding in high-EMI environments.

- Power Stability: Ensure voltage regulation to prevent damage from surges or drops.

山西鑫业达国际贸易有限公司 specializes in BENTLY NEVADA 3500/42M 140734-02 and automation solutions. Visit www.xydcontrol.com for technical support and product inquiries.