Description

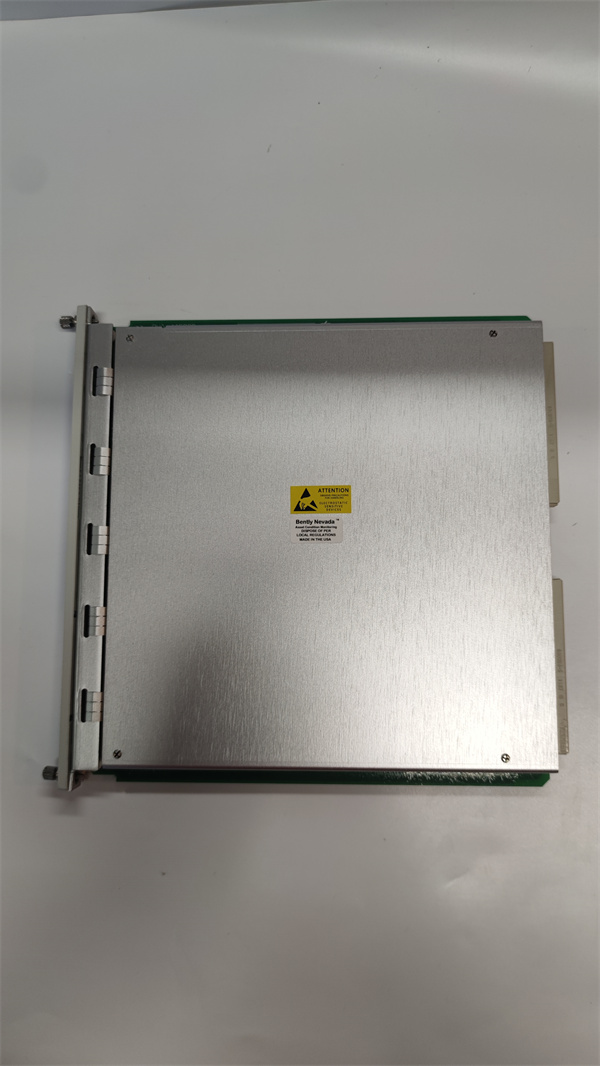

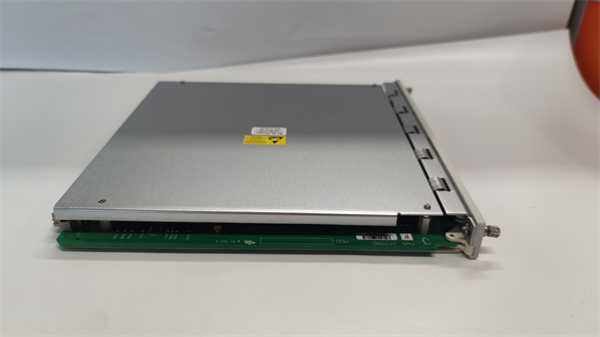

BENTLY 3500/65 145988-02 Temperature Monitoring Module

1. Product Description

The BENTLY 3500/65 145988-02 is a high-precision temperature monitoring module designed for industrial machinery in sectors such as power generation, oil and gas, and manufacturing. As part of the BENTLY 3500 System, it provides 16 channels of temperature measurement, supporting both Resistance Temperature Detector (RTD) and isolated tip Thermocouple (TC) inputs. The module processes real-time data, compares it against user-programmable alarm thresholds, and triggers alerts or shutdowns to prevent equipment damage. Its modular design ensures seamless integration with other 3500 Series components (e.g., vibration, speed monitors) for comprehensive machinery protection.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Input Type | RTD (3/4-wire), TC (isolated tip) |

| Channels | 16 |

| Temperature Range | -30°C to +65°C (operating) -40°C to +85°C (storage) |

| Accuracy | ±0.13% of setpoint (alarms) |

| Alarm Delays | Alert: 1–60 seconds Danger: 0.5–60 seconds |

| Power Supply | 24 VDC |

| Communication | DeviceNet, Profibus DP (via 3500 System) |

| Weight | 0.43 kg (0.95 lb) |

| Dimensions | 263 × 58 × 28 mm (10.35 × 2.28 × 1.10 in) |

| Safety Compliance | CE, RoHS |

3. Advantages and Features

- Multi-Sensor Flexibility: Supports RTD and TC inputs for versatile temperature monitoring.

- Precision Alarming: Adjustable thresholds with ±0.13% accuracy to minimize false triggers.

- Triple Modular Redundancy (TMR): Ensures reliable operation in critical applications via dual-voting logic.

- Case Study: A steel plant reduced downtime by 18% by using the 3500/65 to detect overheating in rolling mills before failures occurred.

4. Application Areas and Use Cases

- Industries: Power plants, oil refineries, chemical processing, and metallurgy.

- Key Applications:

- Monitoring bearing temperatures in turbines and compressors.

- Preventing overheating in pumps and motors.

- Condition assessment of rotating machinery in harsh environments.

5. Competitor Comparison

The 3500/65 145988-02 outperforms alternatives with:

- Higher Channel Density: 16 channels in a compact form factor.

- Enhanced Safety: TMR capability for SIL-rated systems.

- Ease of Integration: Seamless compatibility with BENTLY’s System 1 analytics software.

6. Selection Recommendations

- Channel Requirements: Choose this model for applications needing 16+ temperature measurement points.

- Sensor Type: Opt for RTD inputs in stable environments or TC inputs for high-temperature extremes.

- Safety Standards: Select TMR configurations for safety-critical processes (e.g., nuclear or petrochemical).

7. Precautions

- Installation: Ensure proper grounding and shielded wiring to prevent EMI interference.

- Calibration: Regularly verify sensor accuracy using BENTLY’s calibration tools.

- Software Updates: Maintain firmware compatibility with the latest 3500 System software.

Shanxi XinyeDa International Trade Co., Ltd. offers BENTLY 3500/65 145988-02 modules and comprehensive automation solutions. Visit www.xydcontrol.com or contact us for sales, technical support, and customized monitoring systems.