Description

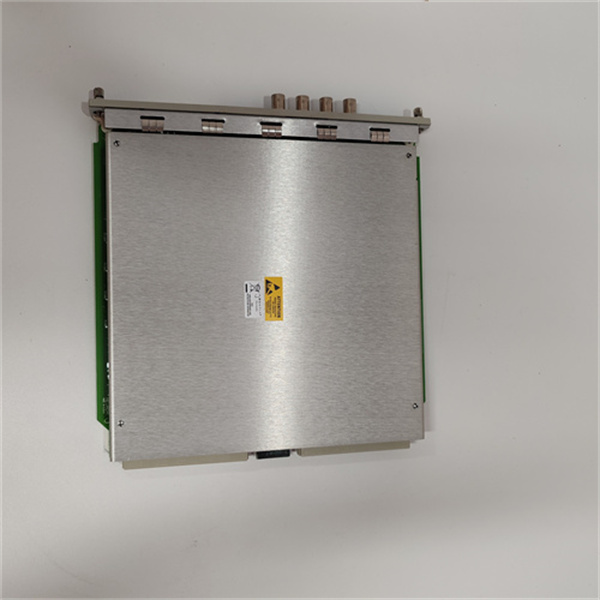

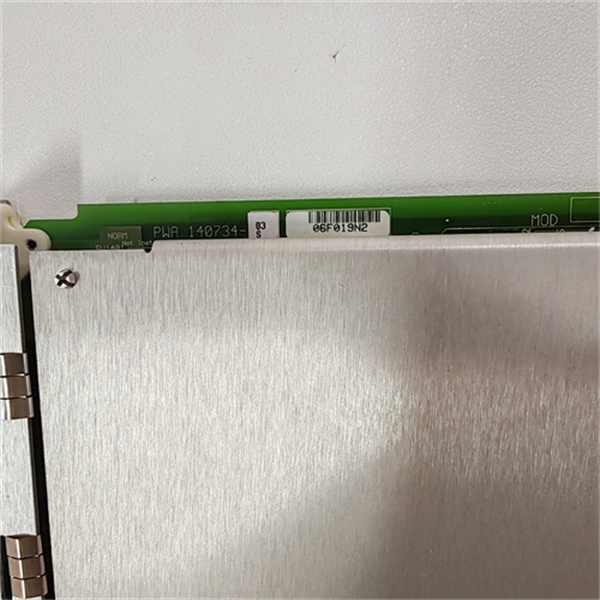

Bently 3500/44M 140734-03 Vibration Monitor

1. Product Description

The Bently 3500/44M 140734-03 is a high-performance vibration monitor designed for aeroderivative gas turbine applications. As part of the Bently Nevada 3500 Series, it provides real-time monitoring of rotating machinery to detect anomalies, prevent failures, and ensure continuous operation. This four-channel device supports inputs from velocity sensors, accelerometers, and proximity probes, making it ideal for critical industries such as power generation, oil & gas, and aerospace. The 3500/44M 140734-03 offers advanced signal processing, including vibration tracking and bandpass filtering, enabling precise analysis of machinery health.

The Bently 3500/44M 140734-03 is a high-performance vibration monitor designed for aeroderivative gas turbine applications. As part of the Bently Nevada 3500 Series, it provides real-time monitoring of rotating machinery to detect anomalies, prevent failures, and ensure continuous operation. This four-channel device supports inputs from velocity sensors, accelerometers, and proximity probes, making it ideal for critical industries such as power generation, oil & gas, and aerospace. The 3500/44M 140734-03 offers advanced signal processing, including vibration tracking and bandpass filtering, enabling precise analysis of machinery health.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Channels | 1–4 channels for vibration measurement |

| Input Types | Velocity transducers, accelerometers, proximity probes |

| Sensitivity | 3.94 mV/(mm/s) (100 mV/(in/s)) or 5.71 mV/(mm/s) (145 mV/(in/s)) |

| Power Consumption | 7.7 W (typical) |

| Dimensions | 241.3 mm × 24.4 mm × 241.8 mm |

| Weight | 0.91 kg (2.0 lbs) |

| Operating Temperature | -40°C to +70°C (-40°F to +158°F) |

| Humidity | 5%–95% non-condensing |

| Communication | Modbus, Ethernet/IP, Profibus |

3. Advantages and Characteristics

- Multi-Channel Monitoring: Simultaneously tracks up to four vibration points for comprehensive analysis.

- Real-Time Fault Detection: Uses advanced algorithms to identify early signs of machinery degradation, reducing downtime.

- Rugged Design: Built to withstand harsh industrial environments, ensuring reliability in extreme conditions.

- Flexible Configuration: Customizable via Bently Nevada’s 3500 Rack Configuration Software for alarm thresholds and signal integration.

4. Application Areas and Cases

- Industries: Petrochemicals, power generation, steel, and aerospace.

- Use Case: In a gas turbine power plant, the 3500/44M 140734-03 continuously monitors shaft vibrations. By detecting a gradual increase in vibration levels, operators were able to schedule maintenance proactively, avoiding a potential $2 million loss from unplanned downtime.

5. Competitor Comparison

Compared to similar vibration monitors, the 3500/44M 140734-03 offers superior signal-to-noise ratio and faster data processing, ensuring higher accuracy in detecting subtle machinery issues. Its modular design also allows seamless integration with existing Bently Nevada systems, reducing installation complexity.

Compared to similar vibration monitors, the 3500/44M 140734-03 offers superior signal-to-noise ratio and faster data processing, ensuring higher accuracy in detecting subtle machinery issues. Its modular design also allows seamless integration with existing Bently Nevada systems, reducing installation complexity.

6. Selection Suggestions

- Compatibility: Ensure compatibility with your existing 3500 Series rack and sensors.

- Environment: Consider temperature and humidity conditions to match the monitor’s specifications.

- Budget: Balance features (e.g., multi-channel vs. single-channel options) with cost requirements.

7. Precautions

- Installation: Follow Bently Nevada’s guidelines for proper wiring and sensor calibration.

- Maintenance: Regularly update firmware and inspect connections to prevent signal loss.

- Safety: Adhere to industrial safety standards when handling high-voltage components.

山西鑫业达国际贸易有限公司 is your trusted partner for Bently 3500/44M 140734-03 and other automation spare parts. Visit www.xydcontrol.com or contact us for sales and technical support.