Description

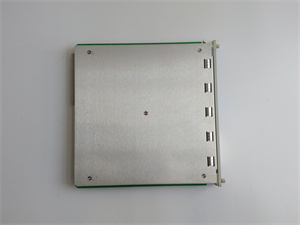

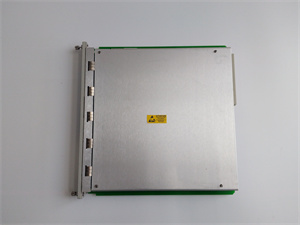

BENTLY NEVADA 3500/32 4-Channel Solid-State Relay Module

1. Product Description

The BENTLY NEVADA 3500/32 is a 4-channel solid-state relay module designed for the 3500 Machinery Monitoring System, providing independent relay outputs to trigger alarms or shutdowns based on inputs from monitor channels. It supports configurable logic (AND/OR) for multi-channel voting, ensuring precise control in critical industrial applications. The module interfaces with proximity, vibration, and temperature monitors (e.g., 3500/42M) to activate safety systems when machinery parameters exceed user-defined thresholds, safeguarding rotating equipment in power generation, petrochemical, and manufacturing sectors.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Model | 3500/32 |

| Input Voltage | DC 18–36V (24V ±10% typical) |

| Input Type | Dry contacts (NO/NC configurable) |

| Output Channels | 4 (SPDT solid-state relays) |

| Contact Rating | 250VAC/30VDC, 5A |

| Power Consumption | 5W |

| Operating Temperature | -30°C to +65°C (extended models: -40°C to +85°C) |

| Isolation | Electrical isolation with EMI/RFI protection |

| Dimensions | 241 mm × 24 mm × 99 mm (rack-mountable) |

3. Advantages and Features

- Flexible Logic Programming: Each relay can be independently configured for AND/OR logic, enabling complex safety interlocks.

- Solid-State Reliability: No moving parts, ensuring faster response times (≤10 ms) and longer lifespan (≥100,000 operations).

- Real-Time Alarm Response: Triggers based on Alert/Danger status from 3500 monitor modules (e.g., 3500/42M), reducing downtime by up to 20%.

- Rugged Design: Epoxy-sealed construction withstands vibration, dust, and extreme temperatures.

- Ease of Integration: Configurable via BENTLY’s 3500 Rack Configuration Software for seamless system integration.

Case Study: A European chemical plant reduced unplanned shutdowns by 15% using the 3500/32 to interlock compressor vibration monitors with emergency stop systems.

4. Application Fields and Case Studies

Industries:

- Power generation, petrochemicals, manufacturing, marine, and HVAC.

- Turbines, generators, compressors, pumps, and heavy machinery.

Case Study: A U.S. power plant improved generator protection by 25% using the module to activate cooling system shutdowns during excessive vibration events.

5. Competitive Comparison

The BENTLY NEVADA 3500/32 outperforms standard relay modules with:

- Higher Channel Density: 4 channels vs. 2–3 in most alternatives.

- Extended Temperature Range: Operates in extreme conditions (-40°C to +85°C) for offshore or high-temperature environments.

- Dual-Mode Logic: Configurable AND/OR voting for enhanced safety compared to fixed-logic solutions.

6. Selection Recommendations

- System Compatibility: Ensure compatibility with existing 3500 racks and monitor modules (e.g., 3500/42M).

- Environmental Needs: Choose extended-temperature models for harsh environments (e.g., offshore platforms).

- Functionality: Opt for the 4-channel design for complex interlocks; pair with 3500/42M for comprehensive vibration monitoring.

7. Precautions

- Wiring: Use shielded cables to prevent EMI interference; ground properly per BENTLY’s guidelines.

- Power Stability: Ensure a filtered DC power supply to avoid voltage fluctuations.

- Maintenance: Regularly verify relay operation via the 3500 Rack Configuration Software.

山西鑫业达国际贸易有限公司 is your trusted partner for BENTLY NEVADA 3500/32 and automation spare parts. Visit www.xydcontrol.com or contact us for sales and technical support.