Description

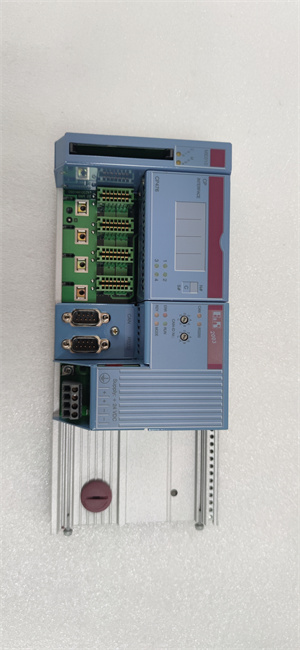

B&R 7CP476-010.9 Product Specification

The B&R 7CP476-010.9 is a high-performance industrial controller designed for advanced automation systems, offering real-time processing, modular scalability, and seamless integration with B&R’s automation platforms.

1. Product Description

The B&R 7CP476-010.9 serves as the central processing unit (CPU) for industrial control systems, delivering fast computation and deterministic performance. Equipped with a 32-bit PowerPC processor running at 400 MHz, it supports complex motion control, machine vision, and high-speed data acquisition. The controller features 256 MB RAM and 256 MB flash memory, enabling efficient program execution and data storage. With Ethernet/IP, PROFIBUS DP, and CANopen connectivity, it integrates effortlessly with field devices, HMIs, and other industrial networks.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Type | Industrial controller |

| Processor | 32-bit PowerPC, 400 MHz |

| Memory | 256 MB RAM, 256 MB flash |

| Communication Interfaces | Ethernet/IP, PROFIBUS DP, CANopen |

| Power Supply | 24 VDC ±10% |

| Operating Temperature | -25°C to +60°C |

| Dimensions | 120 × 50 × 100 mm |

| Weight | 0.4 kg |

3. Advantages and Features

- High-Speed Processing: Processes over 100,000 I/O operations per millisecond, reducing latency in critical applications.

- Multi-Tasking Capability: Supports up to 16 real-time tasks, ideal for concurrent motion control and safety logic.

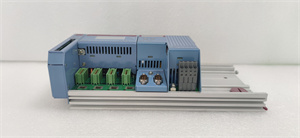

- Flexible Expansion: Connects to B&R’s X20 I/O system for scalable analog/digital input/output configurations.

- Energy Efficiency: Operates at <5 W power consumption, minimizing operational costs.

4. Application Areas and Use Cases

- Automotive Manufacturing: Controls robotic assembly lines and quality inspection systems.

- Packaging Machinery: Manages multi-axis motion for precise labeling and filling operations.

- Renewable Energy: Optimizes grid integration and monitoring in solar/wind power plants.

Case Study: A packaging plant deployed the B&R 7CP476-010.9 to synchronize 20 servo axes for a high-speed bottling line. The controller’s deterministic performance reduced cycle times by 20%, improving overall throughput.

5. Competitor Comparison

- Faster Processor: 400 MHz CPU outperforms many 200–300 MHz alternatives.

- Dual Ethernet Ports: Enables ring topology for redundant network configurations, unlike single-port competitors.

- Integrated Safety: Supports Safety over EtherCAT (FSoE) without additional modules, reducing system complexity.

6. Selection Recommendations

- Performance Requirements: Choose the 7CP476-010.9 for applications requiring >80 I/O points or 10+ motion axes.

- Network Compatibility: Ensure your infrastructure supports Ethernet/IP or PROFIBUS DP.

- Future Scalability: Pair with B&R’s X20 modules for easy expansion of I/O or communication capabilities.

7. Precautions

- Heat Management: Ensure adequate ventilation in enclosures to maintain optimal operating temperatures.

- Software Configuration: Use B&R’s Automation Studio for programming and diagnostics.

- Power Stability: Install surge protectors to prevent voltage fluctuations from damaging the controller.

声明: Shanxi Xinyeda International Trade Co., Ltd. specializes in B&R automation solutions, including the B&R 7CP476-010.9 industrial controller. Visit www.xydcontrol.com for product details or contact us for customized technical support.