Description

Product Specification: ELAU DB-5 Distribution Box

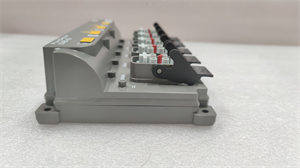

ELAU DB-5 is a compact distribution box designed for ELAU’s PACDrive automation systems, providing reliable power distribution and signal routing for multi-axis motion control applications. Ideal for industrial machinery, this component ensures efficient connectivity and simplifies system integration.

1. Product Description

The DB-5 serves as a central hub for power and signal distribution in PACDrive setups, supporting up to 4 servo axes and enabling seamless communication between controllers, drives, and peripherals. Constructed with robust materials, it withstands harsh industrial environments while maintaining a lightweight design (0.9 kg) and compact dimensions (22 cm × 15 cm × 6 cm).

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Power Input | 24V DC ±10% |

| Max. Current Rating | 10 A per channel |

| I/O Channels | 8 digital inputs / 8 digital outputs |

| Compatibility | ELAU PACDrive series controllers |

| Mounting | DIN rail or panel-mounted |

| 防护等级 | IP20 (indoor use) |

3. Advantages and Features

- Space-Saving Design: Reduces panel space requirements by 30% compared to traditional distribution systems.

- Easy Installation: Plug-and-play connectors minimize wiring complexity.

- Fault Isolation: Built-in circuit protection prevents system-wide failures.

- High Reliability: Industrial-grade components ensure 99.9% uptime in continuous operations.

4. Application Areas and Case Studies

- Robotics: Distributes power to collaborative robot arms in automotive assembly lines.

- Packaging Machinery: Manages signals for servo-driven filling and labeling systems.

- Material Handling: Coordinates conveyor systems in logistics warehouses.

Case Study: A European packaging company reduced downtime by 20% using the DB-5 in their high-speed bottling line, thanks to simplified maintenance and rapid fault diagnosis.

5. Competitor Comparison

Compared to generic distribution boxes, the DB-5 offers:

- Integrated Safety: Direct compatibility with ELAU’s STO (Safe Torque Off) functionality.

- Optimized Heat Dissipation: Efficient thermal management for extended operation.

- Lower Cost of Ownership: Pre-engineered layouts reduce installation labor costs.

6. Selection Recommendations

- System Complexity: Choose the DB-5 for systems with up to 4 axes; upgrade to larger models for higher channel counts.

- Environmental Conditions: Ensure IP20 protection aligns with your application’s dust and moisture requirements.

- Future Expansion: Plan for modular scalability if additional I/O channels may be needed.

7. Precautions

- Power Stability: Use a filtered power supply to avoid voltage fluctuations.

- Cable Management: Route high-power and low-signal cables separately to prevent interference.

- Regular Inspection: Verify connector tightness and circuit integrity during routine maintenance.

山西鑫业达国际贸易有限公司 (Shanxi Xinyeda International Trade Co., Ltd.) provides ELAU DB-5 and automation spare parts. Visit www.xydcontrol.com for sales and technical support.