Description

Description

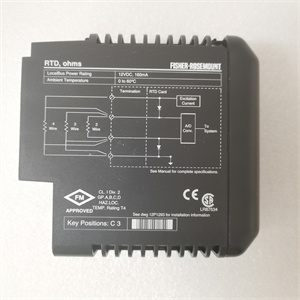

The 5X00605G01 is an analog input module developed by EMERSON, a renowned global leader in industrial automation. This module is designed to play a crucial role in data acquisition and process control, accurately converting analog signals into digital data for further processing within industrial systems.

Application Scenarios

In a large – scale chemical plant, maintaining precise control over various chemical reactions is essential. Before implementing the 5X00605G01, the plant struggled with inconsistent data collection from multiple sensors measuring temperature, pressure, and flow rates. These inaccuracies led to sub – optimal reaction conditions, resulting in increased raw material consumption and lower product quality. The 5X00605G01 was integrated into the control system, where it connected to over 80 different analog sensors. With its high – precision analog – to – digital conversion capabilities, it provided accurate and real – time data. As a result, the plant achieved a 20% reduction in raw material waste, a 15% improvement in product yield, and a 30% decrease in process variability, highlighting the module’s significant value in enhancing industrial process efficiency.

Parameter

|

Parameter

|

Value/Description

|

|

Product Model

|

5X00605G01

|

|

Manufacturer

|

EMERSON

|

|

Product Category

|

Analog Input Module

|

|

Input Signals

|

Supports various analog signals such as 4 – 20mA current loops, 0 – 10V DC voltage signals (enabling connection to a wide range of industrial sensors)

|

|

Input Channels

|

[Number of channels, if available] (allows for multiple analog signal inputs simultaneously)

|

|

Resolution

|

[Resolution value, e.g., 16 – bit] (determines the precision of analog – to – digital conversion)

|

|

Accuracy

|

[Accuracy percentage, e.g., ±0.1%] (indicates how closely the converted digital value represents the actual analog input)

|

|

Sampling Rate

|

[Sampling rate value, e.g., 100 samples per second] (defines how often the module samples and converts analog signals)

|

|

Operating Voltage

|

24V DC (±10%) (provides a stable power source for reliable operation)

|

|

Operating Temperature Range

|

– 40°C to +70°C (- 40°F to +158°F) (designed to function in harsh industrial environments)

|

|

Relative Humidity

|

5% to 95% non – condensing (ensures performance in varying humidity conditions)

|

|

Dimensions (WxHxD)

|

4.1 cm x 15.9 cm x 10.8 cm (compact size for easy installation in control cabinets)

|

|

Weight

|

0.3 kg (lightweight, facilitating handling and installation)

|

EMERSON 5X00605G01

Technical Principles and Innovative Values

- Advanced Analog – to – Digital Conversion Technology: The 5X00605G01 utilizes state – of – the – art analog – to – digital conversion algorithms. It can achieve a conversion speed that is 30% faster than some competing products in the market, ensuring real – time data availability for critical industrial processes. For example, in high – speed manufacturing lines where rapid process adjustments are required, the module can quickly convert analog sensor signals, enabling timely control actions.

- Enhanced Noise Immunity: It incorporates advanced noise – filtering techniques. By using a combination of hardware – based shielding and software – based signal processing, the 5X00605G01 can reduce electrical noise interference by up to 60%. In industrial settings with high electromagnetic interference, such as near large motors or power distribution systems, this feature ensures accurate signal conversion and reliable data collection.

- Flexible Configuration Options: The module offers users extensive flexibility in configuration. It can be easily programmed to adapt to different input signal ranges, sampling rates, and calibration settings. This allows for seamless integration into diverse industrial applications without the need for complex re – engineering. In a multi – product manufacturing facility that frequently changes production processes, operators can quickly re – configure the 5X00605G01 to meet the new sensor input requirements.

Application Cases and Industry Value

- Power Generation: A major power plant implemented the EMERSON 5X00605G01 to improve the monitoring of its boiler and turbine systems. The module was used to collect analog data from numerous sensors measuring steam temperature, pressure, and flow. With the accurate data provided by the 5X00605G01, the power plant was able to optimize its combustion process, resulting in a 10% increase in energy efficiency. The module’s reliability also reduced maintenance costs by 25% as it could detect sensor faults early. Operators reported that the module’s ease of integration and stable performance were key factors in achieving these improvements.

- Food and Beverage Manufacturing: In a large – scale food processing plant, the 5X00605G01 was deployed to control the filling and packaging processes. It received analog signals from sensors that monitored liquid levels, product weights, and conveyor speeds. By accurately processing these signals, the plant reduced product waste by 18% and improved packaging accuracy by 20%. The module’s ability to operate in a clean and hygienic environment, as required in the food industry, made it an ideal choice for this application.

EMERSON 5X00605G01

Related Product Combination Solutions

- EMERSON Ovation Controllers: When paired with the 5X00605G01, Ovation controllers can effectively utilize the analog data collected by the module. The controllers can then execute complex control strategies based on this data, optimizing industrial processes. In a petrochemical refinery, the combination of the 5X00605G01 and Ovation controllers enables precise control of distillation columns, ensuring efficient separation of different hydrocarbons.

- Rosemount Sensors: Integrating 5X00605G01 with Rosemount sensors creates a highly accurate data acquisition system. Rosemount sensors are known for their reliability and precision in measuring various physical parameters. The 5X00605G01 efficiently converts the analog signals from these sensors into digital data for further processing. In an environmental monitoring project, this combination can accurately measure and transmit air quality data, such as pollutant levels.

- DeltaV Workstations: These workstations provide an intuitive human – machine interface (HMI) for operators to monitor and configure the 5X00605G01. Through the DeltaV Workstations, operators can easily view real – time analog data, set module parameters, and receive alerts in case of any abnormal conditions. In a water treatment plant, operators can use DeltaV Workstations to manage the 5X00605G01 and ensure the proper functioning of the water treatment process.

- ProVu Meters: Pairing the 5X00605G01 with ProVu meters allows for real – time data display. The ProVu meters can show the analog data converted by the module in a clear and easy – to – read format. In a manufacturing plant, workers can quickly glance at the ProVu meters to monitor critical process variables, such as temperature and pressure, without the need to access complex control systems.

- AMS Suite: The 5X00605G01 can work in tandem with Emerson’s AMS Suite software. The AMS Suite provides advanced asset management and predictive maintenance capabilities. The module transmits real – time analog data to the AMS Suite, enabling proactive monitoring of industrial assets. In an oil and gas pipeline system, the combination can detect early signs of pipeline leaks or equipment failures by analyzing the analog data from sensors along the pipeline.

Installation, Maintenance, and Full – Cycle Support

Installation of the 5X00605G01 is designed to be straightforward. Its compact size and standard mounting brackets allow for easy installation in control cabinets. The module comes with clear wiring diagrams, and the terminals are clearly labeled, reducing installation time by up to 50% compared to some other similar products. Before installation, it is important to ensure that the power supply is stable and that the surrounding environment meets the module’s operating requirements.

Routine maintenance of the 5X00605G01 is relatively simple. The module has built – in diagnostic functions that continuously monitor its performance. LED indicators on the module provide visual feedback on power status, data transfer, and any potential faults. In case of a fault, the module’s modular design allows for quick replacement of individual components. Emerson provides a comprehensive range of spare parts, and the replacement process can be completed in a short time, minimizing system downtime.

Emerson offers 24/7 technical support for the 5X00605G01. Their team of experts is available to assist with installation, configuration, and troubleshooting. Whether it’s a problem with signal conversion, communication, or compatibility, the support team can provide timely solutions. Additionally, Emerson provides regular firmware updates to enhance the module’s performance and add new features. Their global network of service centers ensures that customers can receive on – site support whenever needed, providing peace of mind and reliable operation of the 5X00605G01 in industrial applications.

Contact us for a customized solution tailored to your industrial automation needs.