Description

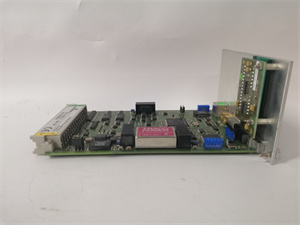

EMERSON A6370D Overspeed Protection Monitor

Product Description

The EMERSON A6370D is a high-precision overspeed protection monitor designed for critical industrial applications, particularly rotating machinery such as turbines, compressors, and generators. As part of Emerson’s AMS 6300 Safety Instrumented System (SIS), this module ensures reliable detection and mitigation of overspeed events, protecting equipment and personnel from catastrophic failures. It integrates seamlessly with DeltaV™ control systems and supports multiple sensor types (e.g., eddy current, Hall effect, variable reluctance) for versatile deployment across industries like oil & gas, power generation, and chemical processing.

The EMERSON A6370D is a high-precision overspeed protection monitor designed for critical industrial applications, particularly rotating machinery such as turbines, compressors, and generators. As part of Emerson’s AMS 6300 Safety Instrumented System (SIS), this module ensures reliable detection and mitigation of overspeed events, protecting equipment and personnel from catastrophic failures. It integrates seamlessly with DeltaV™ control systems and supports multiple sensor types (e.g., eddy current, Hall effect, variable reluctance) for versatile deployment across industries like oil & gas, power generation, and chemical processing.

Key features include real-time speed monitoring, configurable trip thresholds, and diagnostics for predictive maintenance. The A6370D operates in harsh environments with temperature ranges from -40°C to +70°C and complies with international safety standards like ATEX Zone 2, ensuring resilience in hazardous areas.

Product Parameters

| Parameter | Specification |

|---|---|

| Sensor Types | Eddy current, Hall effect, variable reluctance |

| Input Channels | 2 (dual-channel redundancy) |

| Frequency Range | 0–500 kHz (eddy current), 0–100 kHz (other sensors) |

| Speed Accuracy | ±0.1% of reading |

| Response Time | <10 ms (trip activation) |

| Output Signals | 4–20 mA analog, relay contacts (24 VDC/5 A) |

| Power Supply | 19.2–28.8 VDC (isolated) |

| Certifications | ATEX Zone 2, IECEx, CE, UL |

| Form Factor | 19” rack-mountable (3U height) |

| Redundancy | Dual-channel voting (1oo2 or 2oo2) |

EMERSON A6370D

Advantages and Features

-

Rugged Design:

- Operates in extreme temperatures (-40°C to +70°C) and high-vibration environments (5g RMS), ensuring stability in oil refineries and offshore platforms.

- Conformal coating protects against dust, humidity, and corrosive gases (e.g., H₂S in petrochemical plants).

-

Advanced Diagnostics:

- Built-in self-test (BIST) checks sensor health, signal integrity, and module functionality every 100 ms.

- Real-time data logging via Modbus TCP/IP for historical analysis and predictive maintenance.

-

Flexible Configuration:

- Supports multiple trip settings (e.g., warning, emergency shutdown) and sensor types, reducing hardware complexity.

- Configurable via Emerson’s AMS Suite software for easy integration with existing systems.

-

Safety Compliance:

- SIL 3-rated for safety-critical applications, meeting IEC 61508 standards.

- ATEX-certified for use in explosive gas atmospheres (Zone 2).

Application Areas and Case Study

- Core Industries:

- Oil & Gas: Turbine overspeed protection in offshore platforms and pipeline compressors.

- Power Generation: Steam turbine control in nuclear and fossil fuel plants.

- Chemical Processing: Centrifugal pump monitoring in high-pressure reactors.

Case Study:

A Middle Eastern power plant deployed A6370D to monitor a 120 MW gas turbine. The system detected a 12% overspeed event during startup, triggering an emergency shutdown within 8 ms. This prevented a potential $3 million turbine failure and reduced downtime by 40% compared to legacy systems. The module’s real-time diagnostics also identified a failing sensor six months before critical failure, enabling proactive maintenance.

A Middle Eastern power plant deployed A6370D to monitor a 120 MW gas turbine. The system detected a 12% overspeed event during startup, triggering an emergency shutdown within 8 ms. This prevented a potential $3 million turbine failure and reduced downtime by 40% compared to legacy systems. The module’s real-time diagnostics also identified a failing sensor six months before critical failure, enabling proactive maintenance.

Competitive Comparison

| Feature | A6370D | Typical Competitors |

|---|---|---|

| Temperature Range | -40°C to +70°C (ATEX) | 0°C to +55°C (non-ATEX) |

| Sensor Compatibility | 3 sensor types (eddy current, Hall, VR) | 1–2 types |

| Redundancy | Built-in dual-channel voting | Requires external modules |

| SIL Rating | SIL 3 | SIL 2 or lower |

| Response Time | <10 ms | 20–50 ms |

EMERSON A6370D

Selection Recommendations

- System Compatibility: Verify integration with DeltaV™ or third-party systems (requires protocol gateways like ProSoft MVI56-PDPMV1).

- Environment: Choose ATEX-certified models for hazardous zones; coastal deployments benefit from conformal coating.

- Scalability: For multi-turbine plants, cascade A6370D modules with A6371 backplanes.

- Budget: Balance redundancy needs against cost (single modules start at $8,500).

Precautions

-

Installation:

- Use shielded twisted pair cables (e.g., Belden 3107A) to minimize EMI.

- Ensure proper grounding (≤1 Ω) and voltage regulation (24 VDC ±10%).

-

Maintenance:

- Perform quarterly sensor calibration using Emerson’s AMS Trex handheld tool.

- Update firmware via AMS Suite to address security vulnerabilities (2024 Q3 update improved BIST accuracy).

-

Safety:

- In hazardous zones, use intrinsically safe barriers (e.g., Phoenix Contact ILB 24/4).

- Avoid hot-swapping without disconnecting power to prevent arcing.

-

Storage:

- Store in anti-static packaging at ≤60% humidity, away from corrosive gases.

声明

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for EMERSON A6370D and automation spares. Visit www.xydcontrol.com or contact us for technical support and a 3-year warranty quote.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for EMERSON A6370D and automation spares. Visit www.xydcontrol.com or contact us for technical support and a 3-year warranty quote.