Description

Description

The FBM201D is an analog input interface module developed by FOXBORO, a leading brand in industrial automation under Schneider Electric. It plays a crucial role in industrial control systems by accurately collecting and transmitting analog signals, providing reliable data support for system control decisions.

Application Scenarios

In a large – scale petrochemical plant, the FBM201D module is used to connect various sensors such as temperature, pressure, and flow sensors. For example, in a reaction tower of an oil refining unit, multiple temperature sensors transmit the measured analog signals to the FBM201D. The module isolates, converts, and processes these signals, then accurately transmits the data to the control system. This ensures that operators can monitor the temperature changes in the reaction tower in real – time, adjust process parameters promptly, maintain the stability of the reaction process, and effectively avoid production accidents caused by temperature 失控,thus guaranteeing product quality and production efficiency.

In the environmental monitoring system of an intelligent building, the FBM201D module is responsible for connecting indoor and outdoor temperature – humidity sensors, air quality sensors, etc. Through precise collection and processing of these analog signals, the environmental data is fed back to the building automation control system. The system automatically adjusts the operation status of air conditioners, ventilation equipment, etc. based on this data, providing a comfortable environment for the people in the building while achieving the goal of energy saving and consumption reduction.

Parameter

| Main Parameters | Value/Description |

|---|---|

| Product Model | FBM201D |

| Manufacturer | FOXBORO (a part of Schneider Electric) |

| Product Category | Analog Input Interface Module |

| Number of Input Channels | 8 isolated and independent channels |

| Input Signal Range | 0 – 10V DC |

| Channel Isolation Method | Current isolation between each analog input channel and other channels and ground |

| Data Conversion Technology | Sigma – delta data conversion technology for high – precision conversion |

| Integration Period | Software – configurable to remove process noise and power line frequency noise |

| Operating Voltage | 24V DC (with an allowable deviation of +5%, – 10%) |

| Operating Temperature Range | – 40°C to +70°C (- 40°F to +158°F) |

| Relative Humidity | 5% to 95% (non – condensing) |

| Altitude Range | – 300 meters to +12000 meters (- 1000 feet to +40000 feet) |

| Dimensions (L x W x H) | Approximately 10.4 cm x 4.5 cm x 11.4 cm |

| Weight | Approximately 0.284 kg |

| Communication Method | Communicates with relevant FCM or FCP via redundant 2 Mbps module fieldbus |

FBM201D

Technical Principles and Innovative Values

- Innovation Point 1: Channel Isolation Technology

Each analog input channel of the FBM201D module is current – isolated from other channels and ground. This design effectively prevents signal interference between channels. Even in a complex electromagnetic environment, it ensures the accuracy of the signals collected by each channel. Compared with traditional non – isolated modules, it greatly improves the stability and reliability of signal transmission and reduces data errors caused by interference. - Innovation Point 2: Sigma – Delta Data Conversion Technology

The module uses advanced Sigma – Delta data conversion technology to provide high – precision data conversion for each channel. This technology can provide a new analog input reading every 25 ms and processes the signal through a configurable integration period to effectively remove process noise and power line frequency noise. By sampling the analog input multiple times over a period of time, averaging the samples, and then transmitting the average value to the controller, it significantly improves the accuracy of the data and provides more reliable input data for industrial control systems. - Innovation Point 3: Compact and Robust Design

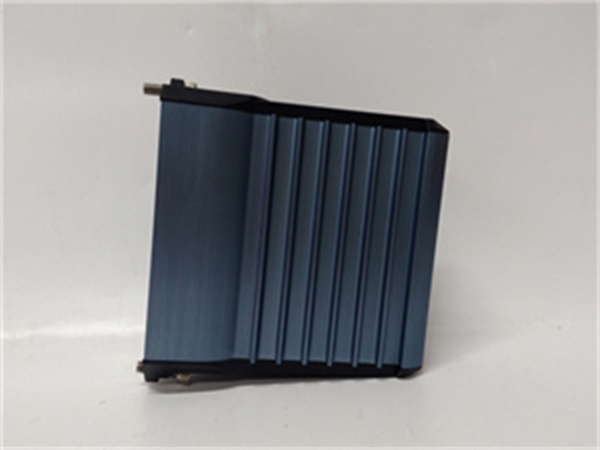

The FBM201D has a compact and robust design structure. Its exterior uses an extruded aluminum shell, which provides good physical protection for the internal circuit. This design makes it suitable for installation in cabinets that meet the G3 class (severe) environment specified in ISA standard S71.04. It can withstand adverse factors such as vibration, shock, dust, and humidity in the industrial environment, ensuring long – term stable operation under harsh conditions.

Application Cases and Industry Value

In a large steel plant, the temperature control of the heating furnace is crucial. Previously, due to the poor performance of the analog input module, the temperature signal collection was inaccurate, resulting in large temperature fluctuations in the heating furnace, which affected the quality of steel and production efficiency. After introducing the FOXBORO FBM201D module, its high – precision signal collection and processing capabilities significantly improved the temperature control accuracy. The temperature fluctuation range was reduced from the original ±10°C to ±2°C, the defective rate of steel was reduced by 15%, and the production efficiency was increased by 10%, bringing considerable economic benefits to the enterprise.

In the pharmaceutical industry, the requirements for temperature and humidity control in the production environment are extremely strict. A pharmaceutical company uses the FBM201D module to build an environmental monitoring system to monitor the temperature and humidity of the production workshop and warehouse in real – time. The module accurately collects the analog signals from the temperature and humidity sensors and timely transmits the data to the control system. When the temperature and humidity exceed the set range, the system automatically starts air conditioners, dehumidifiers, and other equipment for adjustment. Through this precise environmental control, the quality stability of the drugs is effectively guaranteed, the product qualification rate is increased from 95% to 98%, and the loss of drug scrapping caused by environmental factors is reduced.

FBM201D

Related Product Combination Solutions

- Combination with FOXBORO FCM Series

The FBM201D can work in coordination with the FOXBORO FCM (Fieldbus Communication Module) series of fieldbus communication modules. The FCM module is responsible for managing communication with field devices. The FBM201D transmits the collected analog data to the FCM via the fieldbus, and then the FCM further transmits the data to other parts of the control system to achieve data interaction and collaborative control of the entire industrial network. - Combination with FOXBORO FCP

When combined with the FOXBORO FCP (Field Control Processor) field control processor, the analog data collected by the FBM201D is processed and then transmitted to the FCP. The FCP executes control logic based on this data to achieve precise control of industrial processes. For example, in a chemical production process, the FCP controls the opening of valves and the speed of pumps according to the temperature, pressure, and other data transmitted by the FBM201D to ensure that the chemical reaction proceeds under optimal conditions. - Combination with Terminal Assemblies (TAs)

The FBM201D can be used in combination with terminal assemblies (TAs). TAs are used to connect field wiring locally or remotely to the FBM201D module and support the connection of single – channel internal and/or external loop – powered transmitters. This combination facilitates the connection between field devices and the module and improves the convenience of system installation and maintenance.

Installation, Maintenance, and Full – Cycle Support

- Installation

The installation process of the FBM201D module is relatively simple. Due to its compact design, it can be easily installed in a standard control cabinet. During installation, simply connect the signal lines, power lines of the field sensors, and the communication lines with the control system according to the clearly marked interfaces on the module. Before installation, ensure that the temperature, humidity, and other conditions of the installation environment meet the working requirements of the module, and check whether the power voltage is within the specified range. - Maintenance

The module has certain self – diagnostic functions and can display the working status, communication status, and whether there is a fault of the module through indicator lights. In daily maintenance, maintenance personnel can regularly check these indicator lights to detect potential problems in a timely manner. When the module fails, due to its modular design, the module can be easily replaced without removing the wiring, power, and communication cables of the field devices. FOXBORO provides a rich variety of high – quality spare parts to ensure the normal operation of the system is restored in the shortest possible time. - Full – Cycle Support

FOXBORO provides comprehensive full – cycle support services for the FBM201D module. From the pre – sales consultation stage of the product, professional technical advice and solutions are provided to customers; during the sales stage, timely product delivery and installation guidance are ensured; in the after – sales stage, long – term technical support, firmware updates, and fault repair services are provided. Through regular firmware updates, the performance and functions of the module are continuously optimized to better adapt to the ever – developing industrial automation requirements.