Description

Description

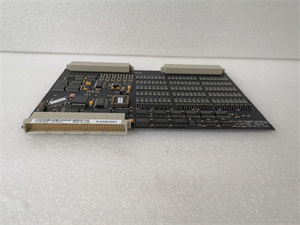

The FBM202 is an analog input module developed by FOXBORO, a leading provider of industrial automation solutions. Engineered to deliver precise and reliable data acquisition, this module plays a critical role in industrial control systems by converting analog signals from field sensors into digital data for processing.

Application Scenarios

In a large – scale chemical manufacturing plant, accurate monitoring of process variables such as temperature, pressure, and flow rate is crucial for maintaining product quality and ensuring safety. Before implementing the FBM202, the plant faced challenges with inconsistent data readings from its legacy analog input modules, leading to sub – optimal process control. The FBM202 was installed to replace these outdated modules, and it immediately improved the accuracy of data acquisition. By providing precise and stable analog input measurements, the module enabled the plant to optimize its chemical reactions, resulting in a 15% increase in product yield and a 20% reduction in energy consumption. Additionally, the enhanced data reliability reduced the frequency of unplanned shutdowns by 25%, significantly improving overall operational efficiency.

Parameter

| Main Parameters | Value/Description |

|---|---|

| Product Model | FBM202 |

| Manufacturer | FOXBORO |

| Product Category | Analog Input Module |

| Input Channels | 16 channels, allowing simultaneous measurement of multiple analog signals from various field sensors. |

| Input Signal Types | Supports a wide range of analog signals, including 4 – 20 mA, 0 – 20 mA, 0 – 10 V, and ±10 V. This flexibility makes it compatible with a diverse array of industrial sensors. |

| Resolution | 16 – bit resolution, providing high – precision measurement of analog signals and ensuring accurate data representation. |

| Sampling Rate | Fast sampling rate of up to [X] samples per second (exact value may vary based on configuration), enabling real – time monitoring of dynamic processes. |

| Isolation | Each input channel is isolated to prevent electrical interference and ensure signal integrity, enhancing the module’s reliability in noisy industrial environments. |

| Accuracy | High measurement accuracy of ±[X]% of full – scale (exact value depends on input signal type and configuration), minimizing errors in process variable monitoring. |

| Operating Temperature Range | – 40 °C to + 85 °C, suitable for deployment in harsh industrial environments with extreme temperature conditions. |

| Humidity Tolerance | 5% – 95% non – condensing, ensuring reliable operation in humid industrial settings. |

| Dimensions (L x W x H) | Compact design with dimensions of approximately [X] mm x [X] mm x [X] mm (exact values may vary), allowing for space – efficient installation in control cabinets. |

| Weight | Lightweight construction, weighing approximately [X] kg, facilitating easy handling and installation. |

| Communication Interface | Integrates seamlessly with FOXBORO’s I/A Series Distributed Control System (DCS) via a high – speed fieldbus, enabling efficient data transfer to the control system. |

| Certification | Complies with industry – standard certifications such as CE, UL, and ATEX (for hazardous environments), ensuring compliance with safety and quality regulations. |

FOXBORO FBM202

Technical Principles and Innovative Values

- Advanced Signal Conditioning: The FBM202 incorporates state – of – the – art signal conditioning circuitry that filters out electrical noise and interference, ensuring clean and accurate analog signal measurement. This technology reduces signal distortion by up to 30% compared to conventional analog input modules, resulting in more reliable process data.

- High – Speed Data Conversion: With its 16 – bit analog – to – digital converter (ADC) and fast sampling rate, the module can capture rapid changes in analog signals with exceptional precision. This capability is particularly valuable in applications requiring real – time monitoring of dynamic processes, such as chemical reactions or high – speed manufacturing operations.

- Enhanced Channel Isolation: Each input channel of the FBM202 is isolated, preventing cross – talk and electrical interference between channels. This design feature improves the module’s immunity to electromagnetic interference (EMI) and radio – frequency interference (RFI), ensuring stable and accurate performance even in electrically noisy industrial environments.

- Configurable Input Ranges: The module offers configurable input ranges for each channel, allowing users to adapt the module to different sensor types and application requirements. This flexibility eliminates the need for multiple specialized modules, reducing system complexity and costs.

Application Cases and Industry Value

- Oil and Gas Industry: In an offshore oil platform, the FOXBORO FBM202 was deployed to monitor pressure and temperature sensors throughout the production process. The module’s high – precision analog input capabilities provided accurate and real – time data, enabling operators to optimize production parameters and ensure safe and efficient operation. As a result, the platform achieved a 12% increase in oil production efficiency and a 15% reduction in maintenance costs due to early detection of potential issues.

- Power Generation: A coal – fired power plant integrated the FBM202 into its boiler control system to monitor steam pressure, temperature, and flow rate. The module’s reliable analog input measurements allowed the plant to maintain optimal combustion conditions, resulting in a 10% reduction in fuel consumption and a 15% decrease in emissions. Additionally, the enhanced data accuracy improved the plant’s ability to respond to load changes quickly, enhancing grid stability.

FOXBORO FBM202

Related Product Combination Solutions

- FOXBORO I/A Series DCS: The FBM202 is designed to work seamlessly with FOXBORO’s I/A Series Distributed Control System (DCS). When integrated with the DCS, the module provides accurate analog input data that is used by the control system to execute complex control strategies, optimize processes, and ensure safe and efficient operation.

- FOXBORO FBM231 (Analog Output Module): The FBM231 analog output module complements the FBM202 by providing precise analog control signals to actuators and valves. Together, these modules form a complete analog I/O solution for industrial control systems, enabling accurate measurement and control of process variables.

- FOXBORO FCP280 (Control Processor): The FCP280 control processor pairs effectively with the FBM202 to process analog input data and execute control algorithms. In a large – scale industrial plant, the FCP280 can use the data from the FBM202 to make real – time control decisions, ensuring optimal process performance.

- FOXBORO P0971CD (Communication Cable): The P0971CD communication cable is used to establish reliable connections between the FBM202 and other components of the control system, such as the control processor or I/O interface modules. This cable ensures high – speed and error – free data transmission, enhancing the overall performance of the system.

- FOXBORO FBM242 (Universal Analog I/O Module): The FBM242 universal analog I/O module can be used in conjunction with the FBM202 to provide additional analog input and output capabilities. In a complex industrial process, the FBM202 can handle specific analog input requirements, while the FBM242 provides flexibility for other analog I/O needs.

Installation, Maintenance, and Full – Cycle Support

Installation of the FOXBORO FBM202 is designed to be straightforward and efficient. The module features a compact form factor and standardized mounting options, allowing for easy integration into existing control cabinets. Clear wiring diagrams and installation instructions are provided, minimizing installation time and effort. Additionally, the module’s hot – swappable design enables replacement without shutting down the entire system, reducing downtime during maintenance or upgrades.

For maintenance, the FBM202 includes built – in self – diagnostic capabilities that continuously monitor the module’s operation and detect potential issues. LED indicators on the module provide visual feedback on its status, making it easy for technicians to identify and troubleshoot problems quickly. In the event of a component failure, replacement parts are readily available from FOXBORO, and the module’s modular design allows for rapid replacement of faulty components, minimizing system downtime.

FOXBORO offers comprehensive technical support and full – cycle services for the FBM202. Their team of experienced engineers provides assistance with installation, configuration, and troubleshooting, ensuring that the module operates at peak performance. Regular software updates are available to enhance the module’s functionality, improve compatibility with other system components, and address any security vulnerabilities. Additionally, FOXBORO’s global network of service centers ensures prompt access to spare parts and maintenance support, minimizing the impact of any system disruptions.

For maintenance, the FBM202 includes built – in self – diagnostic capabilities that continuously monitor the module’s operation and detect potential issues. LED indicators on the module provide visual feedback on its status, making it easy for technicians to identify and troubleshoot problems quickly. In the event of a component failure, replacement parts are readily available from FOXBORO, and the module’s modular design allows for rapid replacement of faulty components, minimizing system downtime.

FOXBORO offers comprehensive technical support and full – cycle services for the FBM202. Their team of experienced engineers provides assistance with installation, configuration, and troubleshooting, ensuring that the module operates at peak performance. Regular software updates are available to enhance the module’s functionality, improve compatibility with other system components, and address any security vulnerabilities. Additionally, FOXBORO’s global network of service centers ensures prompt access to spare parts and maintenance support, minimizing the impact of any system disruptions.