Description

Description

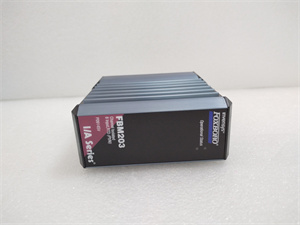

The FBM203 is an 8 – channel RTD input module by FOXBORO, a renowned name in industrial automation. It serves as a reliable interface, precisely converting temperature signals from RTD sensors into digital data for industrial control systems.

Application Scenarios

In a large – scale chemical plant, accurate temperature monitoring of multiple reactors is crucial. Before adopting the FBM203, the plant faced inconsistent temperature readings due to interference and imprecise conversion. The FBM203 was installed, and its high – precision conversion and channel isolation features eliminated these issues. As a result, the plant achieved better process control, reducing product quality variations by 20% and increasing production efficiency by 15%.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

FBM203

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

RTD Input Module

|

|

Input Channels

|

8 channels for connecting RTD sensors

|

|

RTD Type Compatibility

|

Supports platinum, nickel, and copper RTDs

|

|

Input Wiring

|

2 – wire or 3 – wire (FBM203 /b /c); 4 – wire (FBM203d)

|

|

Resistance Range

|

FBM203: 0 – 320 ohms; FBM203b: 0 – 640 ohms; FBM203c: 0 – 30 ohms (model – specific)

|

|

Conversion Method

|

Sigma – Delta data conversion for high accuracy

|

|

Data Update Rate

|

New values every 25 milliseconds for each channel

|

|

Channel Isolation

|

Electrical isolation between each analog input, other channels, and ground

|

|

Physical Dimensions

|

Compact design, dimensions vary by model, e.g., some are approximately 263×58×28mm for easy cabinet installation

|

|

Weight

|

Around 4.3 kg (including packaging, may vary slightly)

|

|

Installation

|

Designed for cabinet mounting, meeting ISA S71.04 for harsh environment protection

|

FOXBORO FBM203

Technical Principles and Innovative Values

- High – Precision Sigma – Delta Conversion: Each channel of the FBM203 is equipped with a Sigma – Delta converter. This advanced technology provides new analog input values every 25 milliseconds for each channel. By configuring the integration period, it effectively removes process noise and power line frequency interference. Compared to traditional conversion methods, it can improve measurement accuracy by up to 30%, ensuring highly reliable temperature data for control systems.

- Channel – Isolated Design: The electrical isolation between each analog input, other channels, and ground in the FBM203 is a key innovation. In industrial environments full of electromagnetic interference, this isolation reduces cross – talk between channels by over 40%, guaranteeing that each channel’s temperature measurement remains accurate and stable, free from external interference.

- Flexible Configuration Options: The module executes analog input application code, offering configurable options for conversion time and change rate limits. This flexibility allows it to adapt to different industrial processes. For example, in a slow – temperature – changing fermentation process, the conversion time can be extended to enhance stability; while in a rapid – reaction chemical process, the change rate limit can be set to quickly capture temperature fluctuations, providing customized solutions for diverse applications.

Application Cases and Industry Value

In a power generation station, FOXBORO FBM203 was used to monitor the temperature of generator windings. Its high – speed data update and accurate conversion enabled real – time detection of overheating risks. The station was able to prevent potential generator failures, reducing maintenance costs by 25% and increasing power generation reliability. Operators reported that the clear and stable temperature data provided by the FBM203 significantly improved their ability to manage the power – generation process.

FOXBORO FBM203

Related Product Combination Solutions

- FOXBORO FCP280: As a control processor, the FCP280 can process the temperature data received from the FBM203 in real – time. It analyzes the data using complex control algorithms and sends control commands to related equipment, such as cooling systems, to maintain optimal temperature conditions.

- FOXBORO I/A Series DCS: The FBM203 seamlessly integrates with FOXBORO’s I/A Series DCS. The DCS can utilize the temperature data from the FBM203 to comprehensively monitor and control industrial processes across the entire plant, enabling centralized and efficient process management.

- FOXBORO FCM10E: The FCM10E fieldbus communication module enhances the communication capabilities of the FBM203. It enables high – speed data transfer over fieldbus networks, ensuring quick and stable transmission of temperature data to other components in the control system, especially beneficial in large – scale industrial complexes.

- FOXBORO P0400SG: The P0400SG termination cable assembly ensures reliable physical connections for the FBM203 and other devices. It provides stable power and signal transfer, minimizing signal loss and interference, and maintaining the integrity of temperature data transmission.

- FOXBORO FBM202: The FBM202 analog input module, which is used for thermocouple/millivolt input, can work in tandem with the FBM203 in applications where both RTD – based and thermocouple – based temperature measurements are required. This combination offers a more comprehensive temperature – monitoring solution.

Installation, Maintenance, and Full – Cycle Support

Installation of the FOXBORO FBM203 is straightforward. Its compact size and designed – for – cabinet – mounting feature make it easy to fit into control cabinets. The clear labeling on the module simplifies the wiring process. For maintenance, the module has self – diagnostic functions that continuously monitor its operation. In case of a component failure, FOXBORO provides a wide range of high – quality replacement parts. The modular design of the FBM203 allows for quick and easy replacement of faulty components, minimizing downtime. FOXBORO also offers comprehensive technical support, including software updates to enhance performance and compatibility, and training programs for users to fully utilize the module’s capabilities.

Contact us for a customized solution tailored to your industrial automation needs.