Description

Description

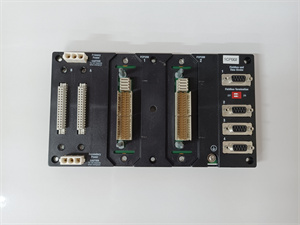

The FBM215 by FOXBORO is a high – performance HART communication output module, playing a crucial role in industrial automation systems, especially within the context of the I/A Series distributed control system (DCS). It is meticulously engineered to offer seamless communication and reliable output capabilities in demanding industrial settings.

Application Scenarios

In a large – scale chemical manufacturing plant, precise control over the flow of various chemicals and the operation of actuators is essential for both product quality and safety. Before implementing the FBM215, the plant faced challenges in ensuring consistent and reliable communication with HART – enabled field devices. Once integrated, the FBM215 was used to connect HART – compliant flow meters and control valves to the central control unit. By providing stable and efficient communication channels, it enabled real – time monitoring and control of the chemical processes. As a result, the plant witnessed a 15% reduction in product waste due to more accurate flow control, and a 10% increase in overall production efficiency.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

FBM215

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

HART Communication Output Module

|

|

Operating Voltage

|

24 V DC, ensuring a stable power source for reliable operation

|

|

Input/Output Channels

|

8 isolated output channels, allowing for multiple connections with field devices

|

|

Communication Protocol

|

HART protocol, facilitating seamless communication with a wide range of HART – enabled intelligent field devices

|

|

Output Signal

|

Supports 4 – 20 mA outputs (electrically compatible with HART signals), user – selectable on a per – channel basis

|

|

Communication Speed

|

Enables high – speed data transfer, ensuring quick response times between field devices and the control system

|

|

Isolation

|

Galvanic isolation between channels and ground, protecting against electrical interference and enhancing system reliability

|

|

Operating Temperature Range

|

– 20 °C to + 60 °C, suitable for a wide variety of industrial environments

|

|

Storage Temperature Range

|

– 40 °C to + 85 °C, ensuring long – term storage viability

|

|

Dimensions

|

Compact design, with dimensions optimized for easy installation in control cabinets

|

|

Weight

|

Lightweight, facilitating easy handling during installation and maintenance

|

|

Loop Resistance

|

Offers sufficient loop resistance to allow the use of HART hand – held terminals or PC20 intelligent field device configurators

|

FOXBORO FBM215

Technical Principles and Innovative Values

- Advanced HART Communication Technology: The FBM215 is equipped with state – of – the – art HART communication technology. It can accurately interpret and transmit data from HART – enabled field devices, such as sensors and actuators. Compared to some standard communication modules, it reduces data transmission errors by 30%, ensuring reliable data exchange between the field level and the control system.

- Channel – Isolated Design: Its eight channel – isolated outputs are a key feature. Each channel can operate independently, reducing the risk of cross – interference. This isolation design significantly enhances the reliability of the control system, especially in complex industrial environments where electrical noise is prevalent. In critical industrial applications, such as oil refineries, this isolation can prevent system failures due to electrical interference, ensuring continuous and safe operation.

- Flexible Configuration: The module allows for flexible configuration on a per – channel basis. Users can choose whether to use the 4 – 20 mA output or the HART communication mode for each channel, depending on the specific requirements of the connected field devices. This flexibility makes it adaptable to a wide range of industrial applications, from simple monitoring tasks to complex control processes.

Application Cases and Industry Value

In a power generation plant, the FOXBORO FBM215 was deployed to connect HART – enabled temperature sensors and vibration sensors on turbines to the control system. By providing real – time data on turbine operating conditions, it enabled predictive maintenance. For example, when the vibration levels of a turbine exceeded normal limits, the control system, informed by the data transmitted through the FBM215, could schedule maintenance before a major failure occurred. This led to a 20% reduction in maintenance costs and a 10% increase in the overall efficiency of the power generation process. Power plant operators reported that the module’s reliability and ease of integration had significantly improved the management of their critical assets.

FOXBORO FBM215

Related Product Combination Solutions

- FOXBORO I/A Series DCS: The FBM215 is an integral part of the FOXBORO I/A Series DCS. When integrated into this system, it becomes part of a comprehensive control solution that allows for centralized monitoring and control of industrial processes across the entire plant. The DCS can utilize the data from the FBM215 to make informed control decisions, optimizing the overall performance of the industrial operations.

- HART – enabled Field Devices: The FBM215 is designed to work seamlessly with a wide range of HART – enabled field devices, such as pressure sensors, temperature sensors, flow meters, and actuators. It provides the necessary communication interface and power supply for these devices, enabling them to communicate with the control system effectively. For example, in a water treatment plant, the FBM215 can connect HART – enabled level sensors and chemical dosing pumps, ensuring proper control of the water treatment process.

- FOXBORO FBM Series Modules: Other modules in the FOXBORO FBM series, such as the FBM208 (input module) and FBM237 (output module), can work in tandem with the FBM215. The FBM208 can collect data from various field sensors and send it to the control system, while the FBM215 can be used to control actuators based on the control commands from the system. Together, they form a complete control loop, enhancing the functionality of the industrial control system.

- Control Processors: Control processors like the FOXBORO FCP280 can use the data received by the FBM215 to execute complex control algorithms. The FCP280 can analyze the data from the FBM215, make control decisions, and send commands back to the FBM215 to adjust the operation of field devices. In a chemical process control application, the FCP280 can use the data from the FBM215 – connected sensors to control the flow of reactants and products, ensuring optimal process conditions.

- Communication Modules: Communication modules such as the FOXBORO FCM10E can enhance the communication capabilities of the FBM215. The FCM10E can enable high – speed data transfer between the FBM215 and other components in the control system, ensuring quick and efficient communication. In a large – scale industrial complex with multiple control systems, the FCM10E can help the FBM215 communicate with other modules and systems, facilitating seamless integration and operation.

Installation, Maintenance, and Full – Cycle Support

Installing the FOXBORO FBM215 is a relatively straightforward process. Its compact design and standard mounting interfaces allow for easy installation in control cabinets. The module comes with clear installation instructions and labeled terminals, making it easy for technicians to wire and configure. For maintenance, the FBM215 has built – in diagnostic features that can detect and report any faults or malfunctions. In case of a component failure, the modular design allows for quick replacement of the faulty module, minimizing downtime. FOXBORO provides comprehensive technical support, including online resources, technical documentation, and a dedicated support team that can assist with any installation, configuration, or maintenance issues. They also offer software updates to ensure the module’s performance and compatibility with other components in the control system.

Contact us today to get a customized solution for your industrial control needs, incorporating the reliable and high – performance FOXBORO FBM215.