Description

Description

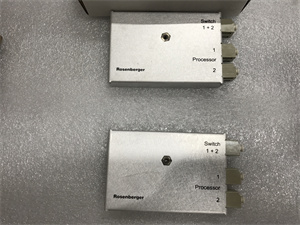

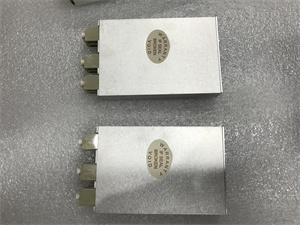

The P0926MX by FOXBORO is a high – performance signal splitter/combiner module, purpose – built to meet the complex demands of industrial control and automation systems. Renowned for its reliability and flexibility, this module is a staple in various industrial setups, enabling seamless signal management and distribution.

Application Scenarios

In a large – scale petrochemical plant, numerous sensors and transmitters are spread across the facility, collecting critical data on temperature, pressure, and flow rates. Before implementing the P0926MX, the plant faced challenges in efficiently distributing these sensor signals to multiple control and monitoring devices. This led to data bottlenecks and inconsistent monitoring, increasing the risk of process inefficiencies and potential safety hazards. However, with the P0926MX installed, it can effortlessly split signals from a single sensor or transmitter, such as a temperature sensor in a distillation column, and distribute them to the control room for real – time monitoring, a data – logging system for historical analysis, and an alarm system for immediate alerting in case of abnormal readings. As a result, the plant has achieved a 25% improvement in process monitoring accuracy and a 20% reduction in unplanned downtime due to improved signal management.

In a power generation station, the P0926MX is used to combine signals from multiple vibration sensors placed on different parts of a turbine. These combined signals are then sent to a central diagnostic system. By accurately combining these signals, the power station can better assess the overall health of the turbine. This has led to a 15% improvement in early – fault detection, allowing for more proactive maintenance and ultimately enhancing the reliability and lifespan of the turbine.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

P0926MX

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Signal Splitter/Combiner Module

|

|

Signal Type Compatibility

|

Supports both analog (e.g., 4 – 20 mA) and digital signals, making it suitable for a wide range of industrial sensors and actuators.

|

|

Number of Channels

|

Can handle 2 to 16 channels, providing flexibility in accommodating different signal distribution or combination requirements. For example, in a manufacturing plant with a large number of sensors, the 16 – channel configuration can be used to efficiently manage signals from multiple production lines.

|

|

Input Impedance

|

Ranges from 100 kΩ to 1 MΩ, ensuring proper signal reception and compatibility with various signal sources.

|

|

Output Impedance

|

Also in the range of 100 kΩ to 1 MΩ, guaranteeing stable signal transmission to connected devices.

|

|

Maximum Signal Voltage

|

Can handle up to 30 V DC or 24 V RMS, suitable for common industrial signal voltage levels.

|

|

Operating Temperature Range

|

Functions reliably from – 40 °C to + 85 °C, capable of withstanding the harsh temperature conditions often found in industrial environments, whether it’s the cold storage areas in a food processing plant or the high – temperature zones in a steel mill.

|

|

Humidity Tolerance

|

Operates in humidity levels from 0 to 95% non – condensing, ensuring stable performance in different humidity conditions, such as the humid environments in a water treatment plant.

|

|

Vibration Resistance

|

Designed to withstand vibrations typically encountered in industrial settings, ensuring the integrity of signal transmission even in the presence of mechanical vibrations from heavy machinery.

|

|

Ingress Protection

|

Offers an ingress protection level, such as IP67 in some models, protecting the module from dust and water ingress, which is crucial for use in outdoor or wet industrial applications.

|

|

Weight

|

Approximately 450 – 460g, with a lightweight design that doesn’t compromise on durability.

|

|

Dimensions

|

Compact dimensions (e.g., 24 cm x 19.8 cm x 5.5 cm), allowing for easy installation in control cabinets and space – constrained industrial setups.

|

FOXBORO P0926MX

Technical Principles and Innovative Values

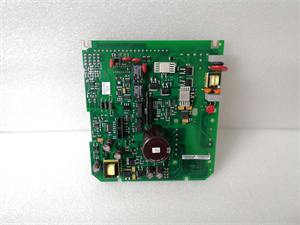

- Versatile Signal Handling: The P0926MX is engineered with advanced circuitry that can accurately split a single input signal into multiple identical outputs or combine multiple input signals into a single output. In the case of analog signals like the 4 – 20 mA standard used in many industrial sensors, the module uses precision resistive networks and signal – conditioning amplifiers to ensure that the split or combined signals maintain their integrity and accuracy. For digital signals, it employs high – speed logic gates and buffer circuits to handle the data flow. This versatility allows for a wide range of applications, from simple sensor signal distribution to complex multi – sensor data aggregation.

- Rugged and Durable Design: Built with industrial – grade materials, the module’s enclosure is designed to withstand harsh environmental conditions. The internal components are also selected for their high – reliability and long – lifespan. In addition to the wide temperature and humidity tolerance, the module is resistant to electromagnetic interference (EMI) and radio – frequency interference (RFI). This is achieved through a combination of shielding techniques and carefully designed circuit layouts. For example, the PCB (Printed Circuit Board) is designed with ground planes and trace routing to minimize the impact of external interference, ensuring stable signal processing even in electrically noisy industrial environments.

- Easy Installation and Maintenance: The P0926MX features a modular design that simplifies installation. It can be easily mounted on a DIN rail, which is a common mounting method in industrial control cabinets. The connectors are designed for quick and secure connection, reducing installation time. For maintenance, the module has built – in diagnostic features. It can continuously monitor the quality of the input and output signals, and in case of any issues such as signal loss, incorrect voltage levels, or impedance mismatches, it can provide diagnostic information, either through an onboard indicator or by communicating with a central monitoring system. This allows for quick troubleshooting and reduces downtime.

Application Cases and Industry Value

- Manufacturing Industry: A leading automotive manufacturing plant was experiencing issues with its production line monitoring system. The signals from various sensors on the assembly line, such as position sensors on robotic arms and quality – control sensors on product inspection stations, were not being distributed effectively to different control and monitoring devices. After installing the FOXBORO P0926MX, the plant was able to split the sensor signals and send them to the production line control system, a quality – control database, and an operator – monitoring console simultaneously. This led to a 30% improvement in production line efficiency as operators could quickly respond to any issues, and quality control was enhanced, reducing the number of defective products by 20%.

- Water and Wastewater Treatment Industry: In a large – scale water treatment facility, the P0926MX was used to combine signals from multiple water quality sensors, including pH sensors, turbidity sensors, and dissolved oxygen sensors. The combined signal was then sent to a central control system for comprehensive water quality analysis. By accurately combining these signals, the treatment plant could better optimize its water treatment processes. As a result, the plant achieved a 10% reduction in chemical usage for water treatment, leading to cost savings and more environmentally friendly operations.

FOXBORO P0926MX

Related Product Combination Solutions

- FOXBORO I/A Series DCS: The P0926MX integrates seamlessly with the FOXBORO I/A Series Distributed Control System (DCS). In an industrial process control application, the I/A Series DCS can use the split or combined signals from the P0926MX to execute complex control strategies. For example, in a chemical processing plant, the DCS can receive temperature and pressure signals from multiple sensors, which have been split and distributed by the P0926MX, and use this data to adjust the flow rates of reactants, ensuring optimal chemical reactions.

- FOXBORO Sensors and Transmitters: When paired with FOXBORO’s extensive range of sensors and transmitters, the P0926MX forms a complete signal management solution. In a power generation plant, FOXBORO’s temperature sensors can send their signals to the P0926MX, which then splits the signals for distribution to the control room, a data – logging system, and an alarm system. This combination ensures accurate and reliable data collection and distribution for effective power plant operation.

- FOXBORO Control Processors: The P0926MX can work in tandem with FOXBORO’s control processors, such as the CP40B/CP60. In a manufacturing plant, the control processors can receive the combined or split signals from the P0926MX and perform high – level control tasks. For instance, the control processor can analyze the aggregated data from multiple production – line sensors (combined by the P0926MX) and make decisions to adjust the production speed or machinery settings for optimal production performance.

Installation, Maintenance, and Full – Cycle Support

Installation of the P0926MX is straightforward. The module comes with clear installation instructions. Mounting it on a DIN rail involves simply snapping it into place, and the connection of signal wires to the appropriate input and output terminals is clearly marked. The connectors are designed to be user – friendly, with features like screw – type terminals for secure wiring.

For maintenance, as mentioned earlier, the module has built – in diagnostic capabilities. Regular maintenance mainly includes visual inspection for any signs of physical damage, such as cracks in the enclosure or loose connections. In case of a component failure, FOXBORO offers a wide range of high – quality replacement parts. The modular design of the P0926MX makes it easy to replace individual components, minimizing downtime.

FOXBORO provides comprehensive full – cycle support for the P0926MX. Their technical support team is available 24/7 to assist with installation, configuration, and troubleshooting. They also offer regular software updates (if applicable) to enhance the module’s performance and compatibility with new systems. With FOXBORO’s support, users can be confident in the long – term reliable operation of the P0926MX in their industrial applications.

Contact us for a customized solution tailored to your industrial signal management needs.