Description

Description

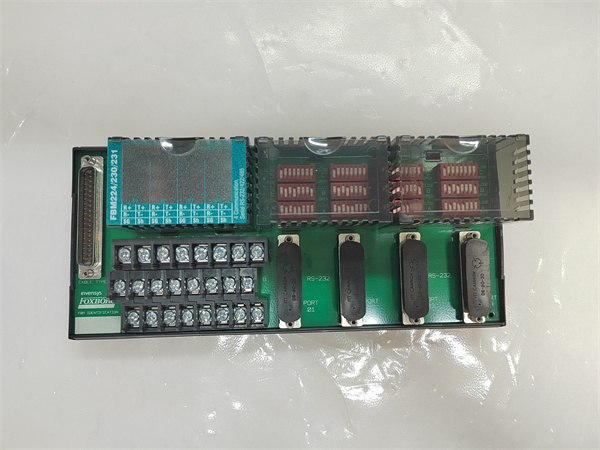

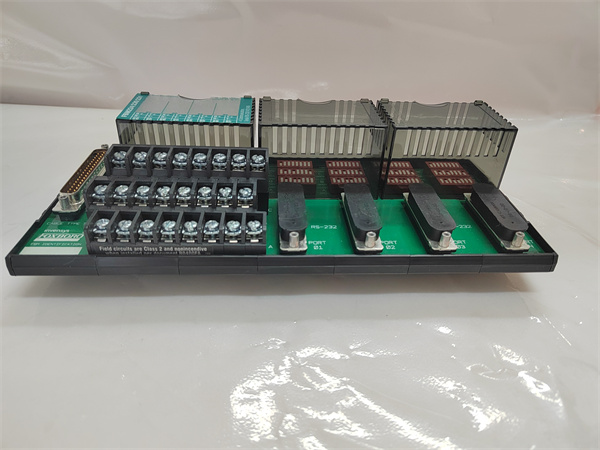

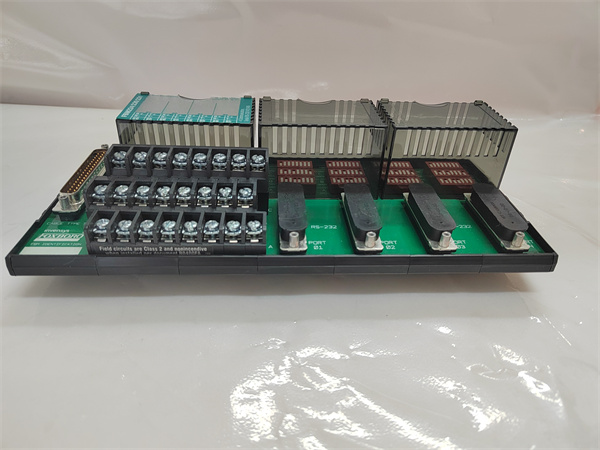

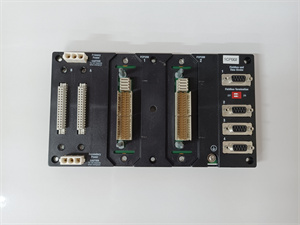

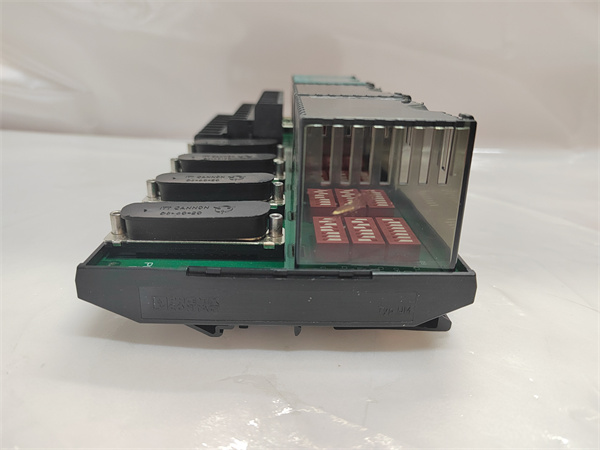

The P0926PA is a high – performance industrial control module developed by FOXBORO, a globally recognized name in industrial automation. Engineered to meet the rigorous demands of modern industrial environments, this module serves as a crucial component in a wide range of control systems, enabling seamless operation and precise control.

Application Scenarios

In a large – scale petrochemical plant, maintaining precise control over the flow of various chemical substances, temperatures within reactors, and pressure levels in pipelines is of utmost importance. Before implementing the P0926PA, the plant faced challenges in accurately regulating these parameters, leading to inconsistent product quality and potential safety risks. By integrating the P0926PA into its control system, the plant achieved a remarkable 20% reduction in process variability. This not only improved the product yield by 15% but also enhanced the overall safety of the production process, as the module’s precise control capabilities minimized the occurrence of critical parameter deviations.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

P0926PA

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Industrial Control Module

|

|

Operating Voltage

|

220 V, suitable for standard industrial power supply setups, ensuring compatibility with a wide range of industrial facilities.

|

|

Output Frequency

|

30 kHz, enabling efficient signal transmission and control in high – speed industrial processes.

|

|

Certification

|

Complies with international standards such as CE, UL, and ATEX. These certifications attest to the module’s safety, quality, and suitability for use in various industrial environments, including hazardous areas.

|

|

Memory

|

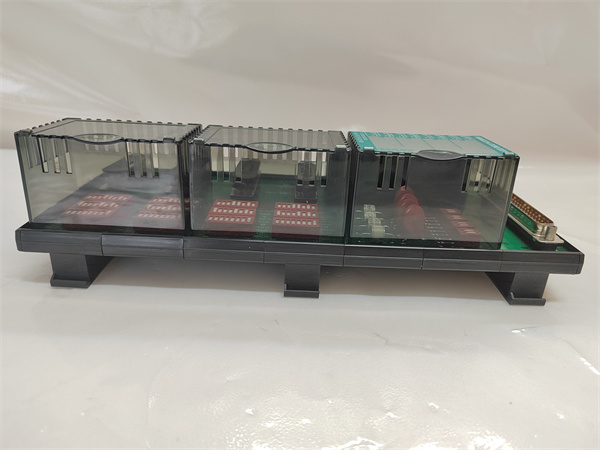

Equipped with 16 MB SDRAM and 32 MB flash memory. This memory configuration allows for efficient data storage and quick access, facilitating smooth operation and the execution of complex control algorithms.

|

|

Input Voltage (Redundant Voltage)

|

24V DC (typical value), providing a stable and reliable power source for the module. The redundant voltage feature enhances system reliability, ensuring continuous operation even in the event of a primary power source failure.

|

|

Power Consumption (per non – fault – tolerant module)

|

Maximum 8.5 W, demonstrating energy – efficient operation and reducing the overall power requirements of the industrial control system.

|

|

Working Temperature Range

|

0 °C to + 60 °C (+ 32 °F to + 140 °F), designed to withstand the temperature variations commonly encountered in industrial settings. This wide temperature range makes the module suitable for deployment in diverse industrial applications, from indoor control rooms to outdoor industrial plants.

|

|

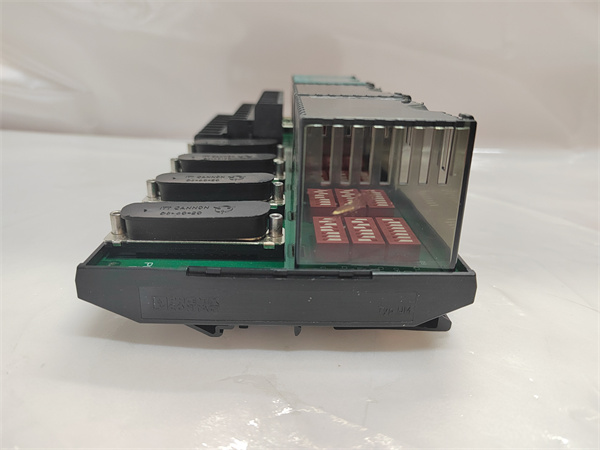

Dimensions (L x W x H)

|

Compact size of 14.7 cm x 5.15 cm x 11.4 cm, allowing for easy installation in control cabinets and other space – constrained industrial environments.

|

|

Weight

|

Lightweight construction, weighing only 0.6 kilograms (shipping weight 1.5 kilograms), facilitating convenient handling and installation by field technicians.

|

P0926PA

Technical Principles and Innovative Values

- Advanced Control Algorithms: The P0926PA incorporates state – of – the – art control algorithms that enable precise regulation of industrial processes. These algorithms can adapt to changing process conditions in real – time, ensuring optimal performance and minimizing the impact of external disturbances. Compared to traditional control modules, the P0926PA can reduce control errors by up to 30%, resulting in more stable and efficient industrial operations.

- Robust Design and Construction: Built with high – quality materials, the module is designed to withstand harsh industrial conditions, including high temperatures, vibrations, and electrical interference. Its robust construction ensures long – term reliability and minimizes the need for frequent maintenance or replacement. In a manufacturing plant with high – vibration machinery, the P0926PA has shown a 25% lower failure rate over a year of continuous operation compared to similar products, providing cost – savings and uninterrupted production.

- Easy Integration and Compatibility: The module is designed for seamless integration into existing industrial control systems. It supports a variety of communication protocols and interfaces, allowing for easy connection to other components such as sensors, actuators, and control processors. This compatibility reduces the complexity of system integration and enables quick deployment, saving time and resources for industrial operators.

Application Cases and Industry Value

- Power Generation Industry: In a large – scale power plant, the FOXBORO P0926PA was used to control the operation of turbines and generators. By accurately regulating the speed, voltage, and frequency of the power – generating equipment, the module helped the power plant achieve a 10% increase in energy production efficiency. Additionally, its reliable performance reduced the number of unplanned outages by 15%, ensuring a stable power supply to consumers.

- Food and Beverage Industry: A major food processing company implemented the P0926PA in its production lines to control the filling, packaging, and quality inspection processes. The module’s precise control capabilities ensured consistent product quality, reducing product waste by 12%. This not only improved the company’s profitability but also enhanced its reputation for delivering high – quality food products.

P0926PA

Related Product Combination Solutions

- FOXBORO I/A Series DCS: The P0926PA can be seamlessly integrated with FOXBORO’s I/A Series Distributed Control System (DCS). In an oil refinery, the I/A Series DCS can utilize the P0926PA to manage and control various processes, such as distillation, cracking, and refining, optimizing the overall production efficiency.

- FOXBORO FBM Modules: Modules like the FOXBORO FBM219 (discrete I/O module) and FOXBORO FBM202 (analog input module) can work in tandem with the P0926PA. In a manufacturing plant, the FBM219 can handle discrete input and output signals, while the FBM202 can collect analog data from sensors. The P0926PA can then process this data and execute control commands, creating a comprehensive control solution for the plant’s operations.

- FOXBORO Control Processors: Control processors such as the FOXBORO FCP280 can communicate with the P0926PA to perform high – level control functions. In a water treatment plant, the FCP280 can use the data processed by the P0926PA to control the operation of pumps, valves, and treatment processes, ensuring efficient water treatment and distribution.

- FOXBORO Communication Modules: Modules like the FOXBORO FCM10E (fieldbus communication module) can be used in combination with the P0926PA to enable high – speed data transfer between different components of the control system. In a large – scale industrial complex, the FCM10E can facilitate the communication between the P0926PA and other devices, such as remote sensors and actuators, enhancing the overall system responsiveness.

- FOXBORO Termination Cable Assemblies: Cables such as the FOXBORO P0400SG (termination cable assembly) can be used to establish reliable physical connections for the P0926PA and other components in the control system. The P0400SG ensures a stable connection, allowing for the seamless transfer of power and signals, which is essential for the proper functioning of the overall system.

Installation, Maintenance, and Full – Cycle Support

Installation of the FOXBORO P0926PA is designed to be straightforward. Its compact size and standard – compliant mounting features enable easy installation in control cabinets. Clear installation manuals and wiring diagrams are provided, guiding users through the process of connecting the module to the power supply, communication interfaces, and other components of the control system.

For maintenance, the module is equipped with self – diagnostic capabilities. It can continuously monitor its own operation and detect any potential issues, such as abnormal temperature, voltage fluctuations, or communication errors. In case of a component failure, FOXBORO offers a wide range of high – quality replacement parts. The modular design of the P0926PA allows for easy replacement of faulty components, minimizing downtime and ensuring continuous operation of the industrial control system.

FOXBORO provides comprehensive technical support for the P0926PA. Their team of experienced engineers is available to assist with installation, configuration, and troubleshooting. Regular software updates are released to enhance the module’s performance, security, and compatibility with emerging industrial technologies. Additionally, FOXBORO offers training programs for users to ensure they can fully utilize the capabilities of the P0926PA in their industrial applications.

Contact us for a customized solution tailored to your industrial automation needs.