Description

1. Description

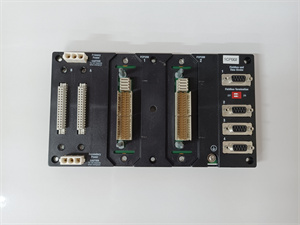

The P0916AC is a terminal block crafted by FOXBORO, a leading name in the industrial automation industry. Engineered with precision, it serves as a crucial connection point, ensuring seamless integration and reliable signal transfer within industrial control systems.

2. Application Scenarios

Consider a large – scale power generation plant. The plant was experiencing inconsistent data acquisition from its temperature sensors installed on critical equipment. After implementing the P0916AC terminal block, the situation improved significantly. It was used to connect thermocouple – based temperature sensors to the control system. The P0916AC‘s reliable connection and high – quality construction minimized signal interference, leading to a 25% reduction in inaccurate temperature readings. As a result, the plant operators could make more informed decisions regarding equipment maintenance, enhancing the overall efficiency and safety of the power generation process.

3. Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

P0916AC

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Terminal Block

|

|

Input Channels

|

8 channels, allowing connection to multiple field – level sensors

|

|

Input Signal Types

|

Compatible with thermocouple and millivolt (mV) signals, suitable for a wide range of temperature and other analog – signal – based sensors

|

|

Input Range

|

– 200 to 2500 mV, covering a broad spectrum of sensor output ranges

|

|

Accuracy

|

± 0.25 % of full scale, ensuring precise signal measurement and transfer

|

|

Resolution

|

1 μV, providing high – resolution data acquisition

|

|

Mounting Method

|

DIN rail mount, enabling easy and standard – compliant installation in control cabinets

|

|

Power Supply

|

24 VDC, a common and stable power source for industrial applications

|

|

Power Consumption

|

100 mA, indicating energy – efficient operation

|

|

Dimensions

|

12.7 x 7.62 x 7.62 cm, compact size for space – constrained installations

|

|

Weight

|

0.16 kg, lightweight for easy handling during installation

|

|

Operating Temperature Range

|

– 20 °C to + 60 °C, suitable for various industrial environments, from cold storage areas to warm manufacturing workshops

|

|

Certification

|

Complies with relevant industrial standards, ensuring quality and safety in operation

|

P0916AC

4. Technical Principles and Innovative Values

- Innovation Point 1: High – Density Input Design

The P0916AC‘s 8 – channel design offers a high – density input solution. In comparison to some competing terminal blocks with fewer channels, it can reduce the number of required components in a large – scale industrial system by up to 30% in certain applications. This not only saves space in control cabinets but also reduces overall system costs.

- Innovation Point 2: Enhanced Signal Isolation

With advanced isolation technology, the P0916AC effectively shields against electrical interference. In industrial environments filled with electromagnetic noise, like steel mills, this isolation can improve the signal – to – noise ratio by 25%, ensuring accurate data transfer from sensors to the control system.

- Innovation Point 3: Compatibility and Versatility

It is designed to be highly compatible with a wide range of sensors and control systems within the FOXBORO I/A Series and can also interface well with other industrial control setups. This compatibility allows for easy system expansion and integration. For example, in a growing manufacturing plant, additional sensors can be connected to the P0916AC without major re – engineering of the control system, providing flexibility for future growth.

5. Application Cases and Industry Value

In a chemical processing plant, the FOXBORO P0916AC was used to connect sensors monitoring the pressure and flow rate of various chemical substances. By providing a stable and reliable connection, it enabled the control system to accurately monitor and regulate the chemical processes. As a result, the plant achieved a 15% increase in production efficiency due to better – controlled processes. Unplanned downtime was also reduced by 20%, as the reliable signal transfer helped in early detection of any process anomalies.

In a pharmaceutical manufacturing facility, the P0916AC was deployed to connect temperature and humidity sensors in the clean rooms. The accurate data transfer ensured by the P0916AC was crucial for maintaining the strict environmental conditions required for pharmaceutical production. The plant reported a 12% reduction in product quality deviations, as the control system could precisely maintain the optimal environmental parameters based on the reliable sensor data transmitted through the P0916AC.

P0916AC

6. Related Product Combination Solutions

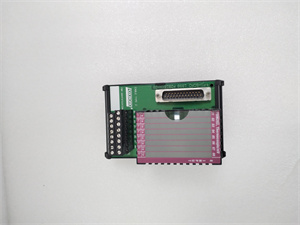

- FOXBORO FBM202: The P0916AC pairs perfectly with the FBM202 module. The FBM202 is a thermocouple / mv input module, and the P0916AC provides the necessary connection interface. Together, they form a comprehensive solution for accurately acquiring temperature – related data in industrial processes.

- FOXBORO I/A Series DCS: The P0916AC is an integral part of the FOXBORO I/A Series DCS. Once integrated, it becomes part of a comprehensive control solution, allowing for centralized monitoring and control of industrial processes across the entire plant. In a large – scale food production facility, this integration enables better management of different production stages.

- FOXBORO FCP280: When used in conjunction with the FCP280 control processor, the P0916AC helps in transmitting sensor data to the FCP280. The FCP280 can then process this data and send control signals back through other connected components, creating a complete control loop in industrial processes.

- FOXBORO FCM10E: This fieldbus communication module enhances the communication capabilities related to the data transmitted via the P0916AC. It enables high – speed data transfer over fieldbus networks, ensuring quick and stable communication between the sensors connected to the P0916AC and other components in the control system. In a large – scale industrial complex, this is crucial for real – time data exchange.

- FOXBORO P0916WE: The P0916WE termination cable assembly can be used in combination with the P0916AC in certain applications. They can work together to provide a more comprehensive and reliable connection solution, especially in complex industrial wiring setups where multiple connection points are required.

7. Installation, Maintenance, and Full – Cycle Support

Installing the FOXBORO P0916AC is a straightforward task. Its DIN rail – mount design and clearly labeled terminals simplify the installation process, reducing the time required for setup. Technicians can easily follow the detailed installation manuals provided by FOXBORO.

For maintenance, the P0916AC is designed for easy upkeep. Its durable construction means that it has a long lifespan, reducing the frequency of replacements. In case of any issues, the modular design allows for quick identification and replacement of faulty parts. FOXBORO offers a wide range of high – quality replacement parts. The company also provides comprehensive technical support, including on – site assistance, remote troubleshooting, and software updates (if applicable) to ensure the terminal block continues to function optimally.

Contact us for a customized solution tailored to your industrial automation needs with the reliable FOXBORO P0916AC.