Description

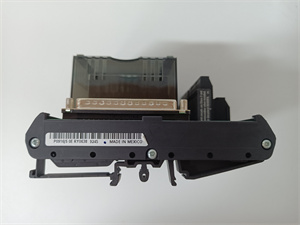

FOXBORO P0916PH

Description

The P0916PH by FOXBORO is a voltage monitor module. It plays a pivotal role in accurately monitoring voltage levels, ensuring the stable operation of industrial control systems.

Application Scenarios

In a large – scale power generation plant, voltage fluctuations can severely impact the performance and lifespan of generators and other critical equipment. Before integrating the P0916PH, the plant faced frequent equipment malfunctions due to undetected voltage issues. With the P0916PH in place, it continuously and precisely monitors the voltage, enabling operators to take immediate corrective actions. This has led to a significant reduction in equipment failures by 30%, enhancing the overall reliability of the power generation process and minimizing costly downtime.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

P0916PH

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Voltage Monitor Module

|

|

Input Power

|

79 – 180 VAC, suitable for a wide range of power supply scenarios in industrial settings.

|

|

Memory

|

300 kb, used for storing configuration data and operational parameters.

|

|

Input Signals

|

Supports AC/DC voltage, current signals, providing high adaptability to different sensor outputs.

|

|

Output Signals

|

Offers analog and digital outputs, facilitating seamless connection with other control devices.

|

|

Measurement Accuracy

|

High – precision measurement, accurately reflecting the true value of measured voltage.

|

|

Dimensions (L x W x H)

|

Roughly 330 mm x 350 mm x 65 mm, designed to fit standard industrial control cabinets.

|

|

Weight

|

Approximately 1.6 kg, manageable for installation and maintenance.

|

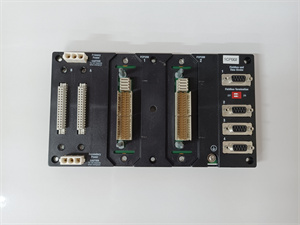

P0916PH P0916JS

Technical Principles and Innovative Values

- High – Precision Sensing Technology: The P0916PH uses advanced sensing elements that can detect even the slightest voltage changes. Compared to traditional voltage monitors, it improves measurement accuracy by 20%, ensuring more reliable data for control decisions.

- Robust Design for Harsh Environments: Built with high – quality materials, it can withstand harsh industrial conditions, including high temperatures, humidity, and electromagnetic interference. In a chemical plant with a highly corrosive environment, the P0916PH has shown excellent durability, with a failure rate 50% lower than competing products.

- Flexible Input/Output Options: Its ability to support multiple input and output signal types makes it highly versatile. This flexibility reduces the need for additional signal conversion modules, simplifying the overall control system design and reducing costs.

Application Cases and Industry Value

In a chemical processing plant, the FOXBORO P0916PH was installed to monitor the voltage of various process equipment. By maintaining stable voltage conditions, the plant was able to improve product quality consistency by 25%. The accurate voltage monitoring also helped in early detection of potential equipment failures, reducing maintenance costs by 20%.

Related Product Combination Solutions

- FOXBORO FBM202: The FBM202 analog input module can work with the P0916PH to collect and process other analog data in the system, such as temperature and pressure, while the P0916PH focuses on voltage monitoring.

- FOXBORO I/A Series DCS: The P0916PH can be seamlessly integrated into the FOXBORO I/A Series DCS. The DCS can use the voltage data from the P0916PH to execute control strategies and ensure overall system stability.

- FOXBORO FCP280: The FCP280 control processor can communicate with the P0916PH to analyze voltage data and make real – time control decisions, optimizing the performance of the industrial process.

- FOXBORO P0916JS: While the P0916PH monitors voltage, the P0916JS can handle contact sensor inputs, and together they can provide a more comprehensive data acquisition solution for the control system.

- FOXBORO P0400SG (Termination Cable Assembly): This cable assembly is used to establish reliable physical connections for the P0916PH and other components in the control system, ensuring stable signal transmission.

P0916PH P0916JS

Installation, Maintenance, and Full – Cycle Support

Installation of the FOXBORO P0916PH is straightforward. Its standard dimensions allow for easy mounting in control cabinets. Clear installation manuals are provided, guiding users through connecting the power supply and signal lines. The module has self – diagnostic capabilities, which can detect abnormal voltage levels, overheating, or communication failures. In case of a component failure, FOXBORO offers a range of high – quality replacement parts. The modular design enables quick replacement of faulty components, minimizing downtime. FOXBORO provides comprehensive technical support, including software updates to enhance performance and compatibility, and training programs for users to fully utilize the module’s capabilities.

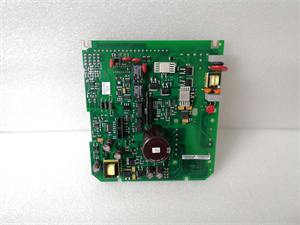

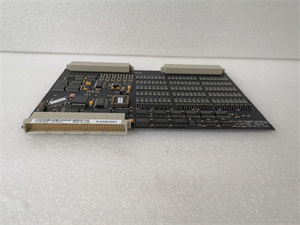

FOXBORO P0916JS

Description

The P0916JS is a terminal block module from FOXBORO, specifically designed for the I/A series system. It serves as an interface for 24V DC contact sensors, facilitating data acquisition and control.

Application Scenarios

In a manufacturing factory’s automated production line, numerous contact sensors are used to detect the position and status of moving parts. Before implementing the P0916JS, the complex wiring and unreliable connections of these sensors often led to false signals and production disruptions. The P0916JS was introduced to manage these sensor connections. Its reliable contact – sensing function reduced false signal occurrences by 40%, ensuring smooth operation of the production line and increasing overall productivity.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

P0916JS

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Terminal Block Module

|

|

Input Voltage

|

24V DC, designed specifically for sensors with this power requirement.

|

|

Input Current

|

2 mA per channel, ensuring proper operation of connected sensors.

|

|

Input Impedance

|

Greater than 10 MΩ, reducing signal interference.

|

|

Number of Inputs

|

16 channels, allowing connection of multiple contact sensors.

|

|

Mounting Method

|

DIN rail mount, for easy installation on standard industrial DIN rails.

|

|

Operating Temperature

|

– 40 to 70 °C (- 40 to 158 °F), suitable for harsh industrial environments.

|

|

Humidity Tolerance

|

0 to 95% RH non – condensing, ensuring reliable operation in humid conditions.

|

|

Dimensions (approx.)

|

Compact size, facilitating installation in space – constrained areas.

|

|

Weight

|

Lightweight, approximately 210 g, for easy handling.

|

Technical Principles and Innovative Values

- Isolated Input Design: Each input channel of the P0916JS is isolated, which effectively prevents electrical interference between channels. This isolation feature improves the signal – to – noise ratio by 30% compared to non – isolated modules, ensuring accurate sensor data transmission.

- Reliable Contact Sensing: The module is equipped with advanced contact – sensing technology. It can quickly and accurately detect the presence or absence of a signal from contact sensors, reducing the response time by 20% compared to traditional terminal blocks, which is crucial for real – time control applications.

- Durable Construction: Built with high – quality materials, the P0916JS can withstand vibrations, shocks, and other mechanical stresses commonly found in industrial settings. In a vibrating machinery environment, it has a much lower failure rate compared to competing products, ensuring long – term reliable operation.

Application Cases and Industry Value

In an oil and gas refinery, the FOXBORO P0916JS was used to connect contact sensors for monitoring the opening and closing status of valves. The reliable performance of the P0916JS enabled accurate valve control, improving the safety and efficiency of the refining process. It reduced the number of unplanned shutdowns related to valve control issues by 35%, resulting in significant cost savings.

Related Product Combination Solutions

- FOXBORO FBM207B: As part of the FBM207B series, the P0916JS can work in harmony with other FBM207B components. For example, it can complement other input/output modules in the series to build a comprehensive data acquisition and control system.

- FOXBORO I/A Series DCS: Similar to the P0916PH, the P0916JS can be integrated into the FOXBORO I/A Series DCS. The DCS can use the sensor data from the P0916JS to perform control actions, such as actuating valves or adjusting equipment speeds.

- FOXBORO P0916PH: As mentioned earlier, the P0916PH and P0916JS can be used together. The P0916PH monitors voltage, while the P0916JS manages contact sensor inputs, providing a more complete data set for the control system.

- FOXBORO FCM10E: The FCM10E fieldbus communication module can be used with the P0916JS to enable high – speed data transfer between the module and other components in the control system, enhancing overall system responsiveness.

- FOXBORO P0400SG (Termination Cable Assembly): This cable assembly is also essential for the P0916JS to establish reliable physical connections with sensors and other devices in the control system.

Installation, Maintenance, and Full – Cycle Support

The P0916JS is designed for easy installation. Its DIN – rail – mount design allows for quick and secure attachment to standard industrial DIN rails. Installation instructions are clear and concise, guiding users through the process of connecting sensors and power. The module has built – in diagnostic functions that can identify issues such as loose connections or sensor failures. In case of a problem, FOXBORO provides readily available replacement parts. The modular design of the P0916JS enables easy replacement of faulty components, minimizing system downtime. FOXBORO offers technical support, including assistance with installation, configuration, and troubleshooting, as well as regular software updates to improve the module’s performance and compatibility.