Description

Product Overview

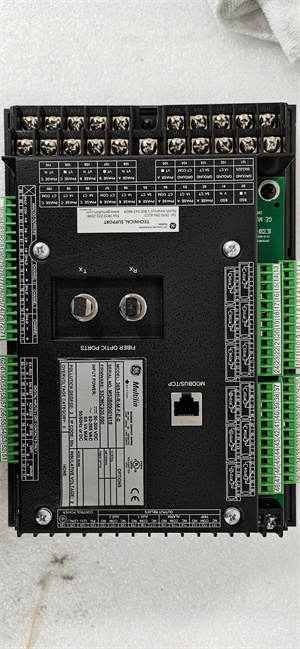

The GE 369 – HI – 0 – M – F – E – 0 is a high – performance motor management relay crafted by GE Multilin, playing a crucial role in industrial control systems. As a part of the 369 series, it is engineered to provide comprehensive protection and monitoring for three – phase motors, which are widely used in diverse industrial scenarios. This relay is designed to ensure the safe and efficient operation of motors, significantly reducing the risk of unexpected failures and associated downtime.

It comes with a metering package that allows for the measurement of various critical parameters related to the motor. These include phase currents, current demand amps, motor load in terms of full – load amps (FLA), unbalanced current percentage, ground current amps, and more. By constantly monitoring these parameters, the GE 369 – HI – 0 – M – F – E – 0 can quickly detect any abnormal conditions in the motor operation. For example, if there is an imbalance in the phase currents, it could indicate a potential problem with the motor windings or an issue in the power supply, and the relay can take appropriate actions. Additionally, it features a fiber optic port, which enables high – speed and reliable communication with other devices in the industrial network, enhancing the overall connectivity and data exchange capabilities within the system.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 369 – HI – 0 – M – F – E – 0 |

| Manufacturer | GE Multilin |

| Product Type | Motor Management Relay |

| Control Power | 50 – 300 VDC / 40 – 265 VAC |

| Power | 20 VA |

| Serial Data Communication | DeviceNet, Profibus DP, Modbus RTU |

| Number of Digital Inputs | 6 |

| Number of Analog Inputs | 2 |

| Number of Analog Outputs | 1 |

| Number of RTD Inputs | 2 |

| Ground Current Input Frequency | 20 – 100 Hz |

| Phase Current Inputs | 1 A and 5 A secondary |

| Waveform Capture Length | 3 buffers containing 16 cycles of all current and voltage channels |

| Number of Recordable Events | Last 512 events |

| Communications | RS232 port, RS485 port |

| Dimensions | Approx: 11.5 in h x 5.5 in w x 8.5 in l |

| Weight | Approx. 10 lbs |

Main Features and Advantages

The GE 369 – HI – 0 – M – F – E – 0 offers several remarkable features. Its metering package is a key strength, as it provides real – time data on a wide range of motor – related parameters. This detailed information helps operators to accurately assess the motor’s health and performance. For instance, by knowing the motor load in real – time, they can optimize the operation of the motor, reducing energy consumption and extending its lifespan.

The relay also has a wide range of communication options, including DeviceNet, Profibus DP, and Modbus RTU. This compatibility allows it to be easily integrated into different industrial automation systems, regardless of the existing communication infrastructure. It can communicate with programmable logic controllers (PLCs), human – machine interfaces (HMIs), and other intelligent devices, enabling seamless data sharing and control.

Moreover, the GE 369 – HI – 0 – M – F – E – 0 has the ability to record up to 512 events. These events can include motor startups, shutdowns, overloads, and other significant occurrences. This event – logging feature is extremely useful for troubleshooting purposes. Maintenance personnel can review these records to identify patterns or past incidents that may have led to current motor problems, facilitating more effective and targeted repairs.

369-HI-0-M-F-E-0

Application Field

The GE 369 – HI – 0 – M – F – E – 0 finds extensive applications across various industries. In manufacturing plants, it is commonly used to protect and monitor motors that drive conveyor belts. By ensuring the proper operation of these motors, it helps to maintain a smooth and continuous production flow. In the pumping systems of water treatment plants or oil refineries, this relay plays a vital role. It can detect any abnormal conditions in the pump motors, such as overheating due to high – pressure differentials or unbalanced loads, and take preventive actions like shutting down the motor or sending an alert to the control room.

In the fan systems of ventilation and air – conditioning setups in large buildings or industrial facilities, the GE 369 – HI – 0 – M – F – E – 0 is used to safeguard the motors. It can monitor parameters like the fan speed (related to motor rotational speed) and the power consumption of the motor. If there is a blockage in the ventilation ducts, the motor may draw more current, and the relay can detect this change and respond accordingly. Similarly, in compressor systems used in industries such as manufacturing, refrigeration, and gas processing, this relay ensures the reliable operation of the compressor motors, protecting them from damage and maintaining the overall efficiency of the compression process.

Related Products

- GE 369 Series Relays: This is the broader series to which the GE 369 – HI – 0 – M – F – E – 0 belongs. Other models in this series may have different configurations, such as variations in communication interfaces, input/output capabilities, or the types of motor parameters they are optimized to monitor. For example, some models might focus more on basic motor protection functions, while the GE 369 – HI – 0 – M – F – E – 0 offers a more comprehensive metering and monitoring package.

- GE PLCs: Programmable Logic Controllers by GE can work in tandem with the GE 369 – HI – 0 – M – F – E – 0. The relay can send motor – related data to the PLC, which can then use this information to make decisions about the overall industrial process. For instance, if a motor in a production line monitored by the GE 369 – HI – 0 – M – F – E – 0 fails, the PLC can adjust the operation of other connected devices to minimize disruptions.

- GE HMIs: Human – Machine Interfaces from GE provide a user – friendly interface for operators to view and interact with the data from the GE 369 – HI – 0 – M – F – E – 0. Through the HMI, operators can access real – time motor parameter readings, event logs, and set alarm thresholds. This allows for easy monitoring and control of the motor management system.

- GE Power Supplies: Appropriate power supplies from GE are essential for the GE 369 – HI – 0 – M – F – E – 0 to function correctly. They ensure a stable and reliable power source, which is crucial for accurate relay operation and the proper monitoring of motor parameters. Different power supply models may vary in voltage output, current capacity, and efficiency to suit various industrial applications.

- Sensor Modules: Various sensor modules can be connected to the GE 369 – HI – 0 – M – F – E – 0 to expand its monitoring capabilities. For example, additional temperature sensors can be attached to provide more detailed temperature data for the motor, while vibration sensors can help detect abnormal vibrations, indicating potential mechanical issues in the motor. These sensors work in synergy with the relay to provide a more comprehensive view of the motor’s condition.

Installation and Maintenance

Pre – installation preparation: Before installing the GE 369 – HI – 0 – M – F – E – 0, carefully verify that the control power supply available in the target system falls within the specified range of 50 – 300 VDC / 40 – 265 VAC. Inspect the relay for any visible signs of damage during transit, such as cracks on the casing or loose components. Familiarize yourself with the wiring diagrams provided in the product manual. Ensure that all the devices that will be connected to the relay, such as motors, sensors, and communication cables, are in proper working condition and their specifications are compatible with the GE 369 – HI – 0 – M – F – E – 0. Clean the installation area to prevent dust or debris from interfering with the relay’s operation.

Maintenance recommendations: Regularly monitor the GE 369 – HI – 0 – M – F – E – 0 for any abnormal behavior. Check the communication ports (RS232 and RS485) to ensure there are no connection issues or communication errors. Periodically review the event logs to identify any recurring problems or potential issues with the motor. Clean the relay gently to remove dust, as dust accumulation can cause overheating and affect performance. Check the connections of all cables and wires to ensure they are secure. If any problems are detected, such as incorrect parameter readings or false alarms, refer to the troubleshooting section of the product manual or contact GE’s technical support for assistance.

Product Guarantee

GE stands firmly behind the quality of the GE 369 – HI – 0 – M – F – E – 0. The product comes with a comprehensive quality assurance program. During the specified warranty period, if the relay is found to have defects in materials or workmanship, GE will provide free repair or replacement services. Their dedicated technical support team is always available to assist customers. Whether it’s answering installation – related queries, helping with troubleshooting complex issues, or providing advice on optimizing the relay’s performance, GE ensures that customers get the best possible service. This commitment to quality and customer satisfaction reflects GE’s confidence in the GE 369 – HI – 0 – M – F – E – 0 and its ability to perform reliably in demanding industrial applications, providing peace of mind to users relying on this motor management relay for their industrial operations.