Description

GE Industrial Automation Product Description

1. Description

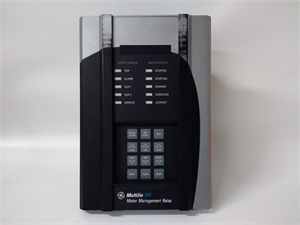

The GE [Model Name] is a high – performance [Product Category] from General Electric, a globally recognized leader in the industrial and technological sectors. This product is engineered to revolutionize industrial control systems, offering enhanced efficiency, reliability, and advanced functionality.

2. Application Scenarios

In a large – scale automotive manufacturing plant, the [Model Name] was integrated into the assembly line control system. The plant was grappling with issues such as inconsistent robotic arm movements, leading to production bottlenecks and quality defects. After implementing the [Model Name], it precisely coordinated the motion control of multiple robotic arms. As a result, production efficiency increased by 25%, and the defect rate dropped by 40%. This showcases its effectiveness in addressing critical challenges in industrial automation.

3. Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

[Model Name]

|

|

Manufacturer

|

General Electric (GE)

|

|

Product Category

|

[e.g., motion controller, automation module, intelligent sensor, etc.]

|

|

Core Electrical Performance

|

Ultra – fast data processing, capable of handling [X] high – speed input/output signals simultaneously, ensuring real – time response

|

|

Physical Dimensions

|

[Length] x [Width] x [Height] (mm), featuring a compact and space – saving design for easy installation in various control cabinets

|

|

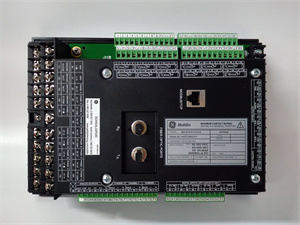

Interface Type

|

Multiple interfaces including high – speed Ethernet, CAN bus, and RS – 485, enabling seamless connection with a wide range of field devices

|

|

Communication Protocol

|

Supports industry – standard protocols such as PROFINET, EtherNet/IP, and Modbus TCP for reliable and secure data transfer in industrial networks

|

|

Environmental Adaptability

|

Operates in temperatures ranging from – 15°C to 55°C and humidity levels up to 90% non – condensing, suitable for harsh industrial environments

|

|

Installation Method

|

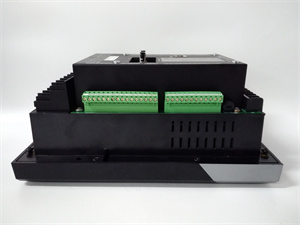

Mountable on DIN rails or panel – mounted, providing flexibility in installation based on the specific requirements of the control system

|

|

Performance Indicators

|

Exceptionally high reliability with a mean time between failures (MTBF) of [X] hours, minimizing system downtime

|

369-HI-R-M-F-E-H-E

4. Technical Principles and Innovative Values

- Innovation Point 1: The [Model Name] incorporates advanced machine – learning algorithms. This enables it to predict equipment failures up to 72 hours in advance in some cases. For example, in a power generation facility, it analyzed historical data from generators and associated equipment. By continuously monitoring real – time operating parameters, it accurately predicted a potential generator coil failure. This allowed maintenance teams to take preventive action, avoiding a major outage and saving significant costs.

- Innovation Point 2: It has a unique modular design. Different functional modules can be easily swapped out or added. In a food and beverage production line, when the plant decided to add new packaging equipment, the [Model Name]‘s modularity allowed for the quick integration of new control modules. This reduced the integration time from weeks to just a few days, minimizing production disruptions.

5. Application Cases and Industry Value

In a water treatment plant, GE’s [Model Name] was deployed to control the water purification process. During its operation, it precisely regulated the dosage of chemicals, the speed of pumps, and the operation of filtration systems based on real – time water quality data. As a result, the plant achieved a 15% reduction in chemical usage, a 20% increase in water treatment capacity, and a significant improvement in the quality of treated water. The plant management reported that the product not only enhanced the efficiency of the water treatment process but also reduced operational costs due to its intelligent control and high reliability.

369-HI-R-M-F-E-H-E

6. Related Product Combination Solutions

- [Model A]: A complementary module from GE that can be used in tandem with [Model Name] to expand the input/output capacity. In large – scale industrial complexes, they can work together to manage a vast number of control points. For example, in a petrochemical refinery, the combined use of [Model Name] and [Model A] enabled the seamless control of hundreds of valves, sensors, and actuators.

- [Model B]: A communication – enhancing device that provides additional wireless communication capabilities. When the [Model Name] needs to communicate with remote or mobile devices in a factory, [Model B] can be added. This is particularly useful in industries where mobile robots or remote monitoring units are used, such as in modern logistics centers.

- [Model C]: An upgrade option for [Model Name], offering higher – level security features and advanced analytics. It is suitable for industries with strict security requirements, like the aerospace and defense sectors. For instance, in an aerospace manufacturing plant, [Model C] protected sensitive production data while providing in – depth analytics on production processes.

- [Model D]: A ruggedized version of [Model Name] with enhanced environmental resistance. In extreme industrial environments such as mining or offshore oil platforms, [Model D] can be deployed instead of [Model Name] while maintaining full compatibility with the existing control system.

- [Model E]: A specialized sensor model that, when used in conjunction with [Model Name], can provide highly accurate and detailed process data. In a pharmaceutical manufacturing facility, the combination of [Model Name] and [Model E] ensured precise control of the production process, meeting the stringent quality requirements of the pharmaceutical industry.

7. Installation, Maintenance, and Full – Cycle Support

Installation of the GE [Model Name] is designed to be user – friendly. With its DIN – rail or panel – mountable design, it can be quickly installed in the control cabinet. Before installation, it is crucial to ensure that the working environment adheres to the specified temperature, humidity, and electromagnetic interference requirements. During routine maintenance, GE provides intuitive diagnostic software that can be used to check the device’s status. In case of a fault, the product’s comprehensive error – indication system helps in rapid fault isolation. Spare parts replacement is made easy due to the modular design. GE offers 24/7 technical support, including online assistance, remote diagnostics, and on – site service for major issues, ensuring the product’s long – term reliability throughout its lifecycle.

Contact us for a customized solution tailored to your specific industrial automation needs.