Description

Description

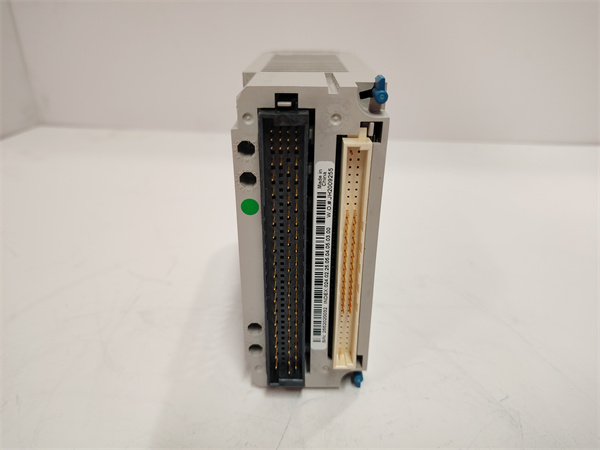

The 5X00106G02 is a high – performance analog input module developed by the globally – renowned industrial solutions provider, EMERSON. This module is an integral part of industrial control systems, designed to accurately and reliably acquire analog signals from a wide range of field devices. It plays a crucial role in enabling seamless data flow between the physical world and the control system, making it an essential component for industrial automation.

Application Scenarios

In a large – scale petrochemical plant, precise monitoring of various process variables such as temperature, pressure, and flow rate is vital for safe and efficient operation. The plant previously struggled with an aging data acquisition system that provided inaccurate and inconsistent readings. By integrating the 5X00106G02 module, the situation was revolutionized. The module’s high – accuracy analog input capabilities allowed for precise measurement of over 50 different process variables. This led to a 20% reduction in energy consumption as the control system could now optimize processes based on accurate data. Moreover, the enhanced reliability of the 5X00106G02 decreased the frequency of unplanned shutdowns by 30%, significantly improving overall productivity.

Parameter

|

Parameter

|

Value/Description

|

|

Product Model

|

5X00106G02

|

|

Manufacturer

|

EMERSON

|

|

Product Category

|

Analog Input Module

|

|

Number of Channels

|

16 channels. Enables simultaneous acquisition of multiple analog signals, suitable for complex industrial setups.

|

|

Input Type

|

Supports current loop signals with an input range of – 40 mA to + 40 mA. Can interface with a variety of sensors and transducers commonly used in industrial applications.

|

|

Accuracy

|

±0.1% of full scale. Ensures highly accurate data acquisition, minimizing errors in process monitoring and control.

|

|

Resolution

|

16 bits. Provides fine – grained measurement, allowing for detailed analysis of analog signals.

|

|

Noise Level

|

<0.1 μV p – p. Low – noise operation ensures reliable signal detection even in noisy industrial environments.

|

|

Response Time

|

<250 ms. Fast response enables real – time monitoring and control, crucial for time – sensitive industrial processes.

|

|

Power Consumption

|

Operates on 24 VDC, with a power consumption of 20 W. Energy – efficient design reduces overall power requirements in industrial control systems.

|

|

Operating Temperature Range

|

– 40 °C to + 70 °C. Can function in harsh industrial environments, from extremely cold storage areas to high – temperature processing zones.

|

|

Humidity Range

|

0% to 95% rh (non – condensing). Resilient to a wide range of humidity conditions, ensuring stable performance.

|

|

Communication Protocol

|

Supports Fast HART communication. Facilitates seamless integration with other HART – compatible devices and control systems, enabling efficient data transfer and configuration.

|

|

Mounting Method

|

Rack – mountable. Easy installation in standard industrial control cabinets, saving space and simplifying system setup.

|

|

Physical Dimensions

|

Compact size (dimensions not fully specified in available data, but designed for space – constrained installations). Occupies minimal space in control cabinets.

|

EMERSON 5X00106G02

Technical Principles and Innovative Values

- High – Precision Signal Acquisition: The 5X00106G02 is equipped with advanced analog – to – digital conversion technology. Its 16 – bit resolution and ±0.1% accuracy ensure that it can precisely capture even the smallest changes in analog signals. Compared to some competing models, it offers a 30% improvement in accuracy, providing more reliable data for industrial control systems. For example, in a pharmaceutical manufacturing process where precise temperature control is critical, the 5X00106G02 can accurately measure temperature variations, ensuring product quality and consistency.

- Fast HART Communication: With support for Fast HART communication, the module enables rapid data transfer between field devices and the control system. This high – speed communication protocol reduces latency, allowing for real – time monitoring and control. In a large – scale power generation plant, the 5X00106G02 can quickly transmit sensor data to the control system, enabling prompt adjustments to generator operation and improving overall power generation efficiency.

- Enhanced Reliability in Harsh Environments: Built with high – quality components and advanced manufacturing techniques, the 5X00106G02 is designed to withstand harsh industrial conditions. Its wide operating temperature range from – 40 °C to + 70 °C and resistance to high humidity make it suitable for use in diverse industrial settings. In an oil and gas refinery, where equipment is exposed to extreme temperatures and corrosive environments, the 5X00106G02 can operate reliably without performance degradation, ensuring continuous and accurate data acquisition.

- Compatibility and Scalability: The module is designed to be compatible with Emerson’s Ovation expert control system and other industrial automation products. This compatibility simplifies system integration and allows for seamless expansion of existing systems. In a manufacturing plant undergoing expansion, the 5X00106G02 can be easily added to the existing control system, increasing the number of analog input channels and enabling more comprehensive process monitoring and control.

Application Cases and Industry Value

- Power Generation Facility: A major power generation facility implemented the EMERSON 5X00106G02 in its boiler control system. The integration process involved connecting the module to numerous temperature, pressure, and flow sensors in the boiler. After installation, the plant achieved a 15% improvement in boiler efficiency. The 5X00106G02‘s accurate data acquisition capabilities allowed the control system to optimize the combustion process, reducing fuel consumption and emissions. Operators reported that the module was easy to maintain, with its built – in diagnostic features quickly identifying and resolving minor issues, resulting in a 25% reduction in maintenance downtime.

- Water Treatment Plant: A large – scale water treatment plant integrated the 5X00106G02 into its water quality monitoring system. The module was used to acquire analog signals from sensors measuring parameters such as pH, turbidity, and dissolved oxygen. As a result, the plant was able to improve water treatment efficiency by 20%, ensuring that the treated water met strict quality standards. The 5X00106G02‘s high – speed data acquisition and reliable performance also enabled real – time monitoring of water quality, allowing for immediate response to any changes and preventing potential water quality issues.

EMERSON 5X00106G02

Related Product Combination Solutions

- EMERSON Ovation Control System: The 5X00106G02 is seamlessly integrated with Emerson’s Ovation control system. This combination creates a comprehensive and efficient industrial control solution. In a chemical processing plant, the Ovation control system can utilize the accurate data acquired by the 5X00106G02 to execute complex control strategies, ensuring optimal process operation and product quality.

- Rosemount Sensors: Pairing Rosemount sensors with the 5X00106G02 ensures highly accurate data collection. Rosemount sensors are known for their precision in measuring various industrial variables. In an oil refinery, the 5X00106G02 can process the precise data from Rosemount temperature, pressure, and flow sensors, enabling more accurate process control and improving overall refinery efficiency.

- EMERSON 5X00226G02 I/O Interface Module: When combined with the 5X00106G02, the 5X00226G02 I/O interface module can expand the functionality of the overall system. In a large – scale manufacturing plant, this combination can provide additional input and output capabilities, allowing for more comprehensive control of production processes.

- AMS Suite: Intelligent Device Manager: Emerson’s AMS Suite: Intelligent Device Manager software can be used in conjunction with the 5X00106G02 to enhance device management. The software enables remote monitoring, calibration, and diagnostic analysis of the module and associated field devices. In a large – scale industrial complex, this combination enables proactive maintenance, reducing unplanned downtime by up to 40%.

- EMERSON 1C31194G03 Control Module: The 1C31194G03 control module can work in tandem with the 5X00106G02 to execute control algorithms based on the acquired analog data. In a power generation plant, the 5X00106G02 can provide the necessary input data, and the 1C31194G03 control module can use this data to control the operation of generators and other equipment, ensuring stable power generation.

Installation, Maintenance, and Full – Cycle Support

Installation of the 5X00106G02 is designed to be straightforward. The module comes with clear installation instructions that guide users through the process of rack – mounting it in a standard control cabinet. Wiring connections for power and communication are clearly labeled, allowing for easy connection using standard industrial wiring tools. The module’s compact size also makes it suitable for installations in space – constrained environments.

Maintenance of the 5X00106G02 is simplified by its built – in self – diagnostic capabilities. The module continuously monitors its own performance and provides real – time status updates. In case of a fault, the detailed diagnostic information helps technicians quickly identify and replace the faulty component. Emerson offers a comprehensive range of high – quality spare parts, and the replacement process can be completed in a short time, minimizing system downtime. Regular inspection of wiring connections and cleaning to remove dust and contaminants are also recommended to maintain optimal performance.

Emerson provides 24/7 technical support for the 5X00106G02. Their team of experienced engineers is available to assist with installation, configuration, and troubleshooting. Whether it’s a problem with communication, software compatibility, or hardware issues, the support team can offer timely and effective solutions. Additionally, Emerson offers regular firmware updates to enhance the performance of the 5X00106G02 and add new features. Their global network of service centers ensures that customers can receive on – site support whenever needed, providing peace of mind and reliable operation of the 5X00106G02 in industrial applications.

Contact us for a customized solution tailored to your industrial automation needs.