Description

Product Overview

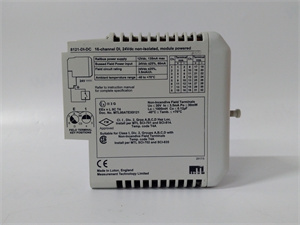

The GE 8121 – DI – DC is a high – performing 16 – channel digital input module, designed to be a vital part of industrial control and automation systems. As part of GE’s renowned product line, it plays a crucial role in accurately capturing and relaying digital signals.

This module is highly versatile, capable of receiving a wide range of digital signals such as switch signals, pulse signals, and level signals. With its 16 input channels, it provides extensive connectivity for various industrial applications. The GE 8121 – DI – DC is built to operate within a – 25°C to + 60°C temperature range, making it suitable for use in diverse environmental conditions. It is often deployed in industrial settings where reliable signal input handling is essential for the smooth operation of the overall system. Whether it’s in a manufacturing plant, a power generation facility, or an industrial automation line, this module ensures seamless integration and efficient signal processing, contributing to enhanced system control and productivity.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 8121 – DI – DC |

| Manufacturer | GE |

| Product Type | Digital Input Module |

| Number of Channels | 16 |

| Input Type | Digital |

| Input Signal Types | Switch, Pulse, Level Signals |

| Input Voltage Range | 24V DC |

| Operating Temperature | – 25°C to + 60°C |

| Storage Temperature | – 40°C to + 85°C |

| Protection Class | IP20 |

| Dimensions | 190 mm × 140 mm × 60 mm |

| Material | Magnesium Alloy |

| Input Impedance | >10 MΩ (for voltage input) |

| Scan Rate | 50 ms |

| Hardware Accuracy (@CMV = 0 V) | ±0.075% of full – scale (23.5°± 2°C); ±0.15% of full – scale (0 to 60°C) |

8121-DI-DC

Main Features and Advantages

High – Density Input Channels

With 16 input channels, the GE 8121 – DI – DC allows for a large number of digital signal sources to be connected simultaneously. This high – density design reduces the need for multiple smaller modules, simplifying system architecture and saving space in control cabinets.

Versatile Signal Reception

It can receive various digital signals, including switch, pulse, and level signals. This versatility makes it suitable for a wide range of applications, from basic on – off switch monitoring to more complex pulse – based sensor input handling.

Stable Voltage Operation

Operating at a 24V DC input voltage, the module provides stable performance. The defined voltage range ensures compatibility with common industrial power supplies and reduces the risk of voltage – related signal errors.

Robust Construction

Made of magnesium alloy, the 8121 – DI – DC is durable and can withstand harsh industrial environments. The IP20 protection class shields it from solid objects larger than 12.5 mm, protecting the internal components from dust and accidental contact.

Accurate Signal Processing

The module offers high – accuracy signal processing, with a scan rate of 50 ms and hardware accuracy specifications. This ensures that the digital signals are accurately captured and transmitted to the control system, minimizing the chances of misinterpretation.

Application Field

In manufacturing plants, the GE 8121 – DI – DC is extensively used for monitoring the status of machinery. For example, it can be connected to limit switches on conveyor belts to detect the position of products or to the start – stop switches of production equipment. By accurately relaying these digital signals to the central control system, it helps in optimizing production processes, reducing downtime, and enhancing overall productivity.

Power generation facilities also rely on the 8121 – DI – DC for various monitoring tasks. It can be used to monitor the status of circuit breakers, relays, and other electrical components. In a power plant, the module can receive digital signals indicating the open or closed state of circuit breakers, allowing operators to quickly respond to any electrical faults and maintain a stable power supply.

Automated production lines benefit from the module’s ability to handle multiple digital inputs. It can be integrated with sensors such as proximity sensors, photoelectric sensors, and pressure sensors. These sensors generate digital signals that the GE 8121 – DI – DC can receive and process. The processed signals are then used to control the operation of motors, actuators, and other devices on the production line, ensuring smooth and efficient production.

8121-DI-DC

Related Products

- GE 8115 – DO – DC: This is a digital output module from GE. While the 8121 – DI – DC focuses on receiving digital signals, the 8115 – DO – DC is used to send out digital control signals. They can be used in tandem in an industrial control system, where the input module receives signals from sensors, and the output module controls actuators or other devices based on the processed input.

- GE PAC8000 series modules: The 8121 – DI – DC is part of the PAC8000 family. Other modules in this series, such as analog input/output modules, can be combined with the 8121 – DI – DC to create a comprehensive I/O solution for industrial automation. They share a common platform and communication protocols, enabling seamless integration.

- GE PLC systems: The GE 8121 – DI – DC is designed to interface with GE’s Programmable Logic Controller (PLC) systems. These PLCs use the digital input signals received by the 8121 – DI – DC to execute control logic, making them essential components in industrial control setups.

- GE 8122 – DI – AC: Similar to the 8121 – DI – DC, but it is designed for AC input signals. It provides an alternative for applications where the input signals are in AC form, while the 8121 – DI – DC is optimized for DC input signals.

- GE 8121 – AI – DC: An analog input module. Unlike the digital – only 8121 – DI – DC, this module can receive and process analog signals such as voltage or current in the DC range. In some industrial applications, both digital and analog inputs are required, and these two modules can be used together to meet such needs.

Installation and Maintenance

Pre – installation preparation: Before installing the GE 8121 – DI – DC, ensure that the power supply is stable and provides the correct 24V DC voltage. Check the installation environment to ensure it falls within the specified temperature and humidity range. Clean the area where the module will be installed to prevent dust and debris from affecting its operation. Verify the compatibility of the module with the existing control system, including checking for proper communication protocols and physical mounting space.

Maintenance recommendations: Regularly inspect the GE 8121 – DI – DC for any signs of physical damage, such as cracks or loose connections. Monitor the input signals to ensure they are being accurately received. If there are any issues with signal reception, check the input wiring for breaks or shorts. Periodically clean the module to maintain its performance, especially in dusty environments. If any problems persist, consult the product manual or contact GE’s technical support for assistance.

Maintenance recommendations: Regularly inspect the GE 8121 – DI – DC for any signs of physical damage, such as cracks or loose connections. Monitor the input signals to ensure they are being accurately received. If there are any issues with signal reception, check the input wiring for breaks or shorts. Periodically clean the module to maintain its performance, especially in dusty environments. If any problems persist, consult the product manual or contact GE’s technical support for assistance.

Product Guarantee

GE offers a comprehensive product guarantee for the 8121 – DI – DC module. The company stands behind the quality and reliability of this product, ensuring that it meets the highest industry standards. In case of any manufacturing defects, GE will provide repair or replacement services within the warranty period. Their team of technical experts is available to offer support for installation, configuration, and any operational issues related to the GE 8121 – DI – DC. This commitment reflects GE’s confidence in the product, giving customers peace of mind when integrating it into their industrial control and automation systems.