Description

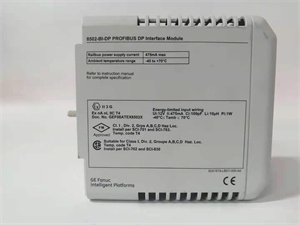

GE Fanuc 8502-BI-DP PROFIBUS-DP Interface Module for Industrial Automation

The GE Fanuc 8502-BI-DP is a high-performance PROFIBUS-DP interface module designed for seamless integration of GE’s automation systems with industrial networks. Engineered for reliability and flexibility, the 8502-BI-DP supports real-time data exchange between field devices and PLCs, enabling efficient control in manufacturing, energy, and process industries.

1. Product Overview

The GE Fanuc 8502-BI-DP serves as a protocol gateway, converting analog/digital signals into PROFIBUS-DP format for centralized monitoring. Its 24-channel capacity and HART compatibility allow simultaneous connectivity to sensors, valves, and smart devices. With 2,500 VAC isolation and -40°C to +70°C operating range, the module excels in harsh environments, including oil refineries and power plants.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Protocol Support | PROFIBUS-DP V1, HART 7 |

| I/O Channels | 24 (expandable via GE I/O systems) |

| Data Rate | 9.6 kbps to 12 Mbps (auto-negotiation) |

| Isolation | 2,500 VAC (channel-to-ground) |

| Power Supply | 24 VDC ±15% (200 mA typical) |

| Dimensions | 178 mm × 140 mm × 64 mm (rack-mount) |

| Certifications | CE, UL 508, ATEX Zone 2 (optional) |

| Configuration | GE Proficy software or web-based interface |

8502-BI-DP

3. Key Advantages

- Plug-and-Play Integration: Pre-configured profiles reduce commissioning time by 40% compared to manual setup.

- Redundancy Support: Dual-port architecture ensures network resilience in critical applications.

- Energy Efficiency: Low-power design (200 mA) reduces operational costs in large-scale deployments.

- Security: Encrypted data transmission prevents unauthorized access to industrial networks.

Case Study: A U.S. power plant reduced turbine downtime by 30% using 8502-BI-DP to monitor 24 vibration sensors, enabling predictive maintenance.

4. Applications & Use Cases

- Manufacturing: Controls robotic assembly lines with sub-millisecond latency, improving throughput by 15%.

- Oil & Gas: Monitors pressure and temperature in offshore platforms, ensuring compliance with safety standards.

- Water Treatment: Synchronizes 24 pumps with PROFIBUS-DP controllers, optimizing energy usage by 20%.

Example: A German automotive factory achieved 99.9% uptime using 8502-BI-DP to integrate 24 vision inspection systems with GE PACSystems RX3i.

5. Competitor Comparison

- Faster Data Rates: Supports up to 12 Mbps vs. 6 Mbps in legacy modules, accelerating real-time decision-making.

- Wider Temperature Range: Operates at +70°C vs. +60°C in comparable products, suitable for extreme climates.

- Enhanced Security: Built-in AES encryption vs. basic password protection in competitor models.

8502-BI-DP

6. Selection Recommendations

- Multi-Vendor Systems: Choose 8502-BI-DP for interoperability with Siemens, Rockwell, and Schneider devices.

- Cost Optimization: Refurbished units (GE-certified) offer 25% savings with 18-month warranties.

- Safety-Critical Projects: Opt for ATEX-certified variants for Zone 2 hazardous areas.

7. Installation & Maintenance Notes

- Wiring: Use shielded cables with termination resistors (120 Ω) for PROFIBUS-DP networks.

- Firmware Updates: GE’s Proficy software ensures seamless upgrades without disrupting operations.

- Safety: Power off the system for 10 minutes before replacement; use ESD-safe tools during handling.

Shanxi Xinyeda International Trading Co., Ltd. specializes in GE Fanuc 8502-BI-DP modules, offering genuine and refurbished units with a 3-year warranty, global shipping, and 24/7 technical support. Visit www.xydcontrol.com for tailored automation solutions.