Description

1. Product Description

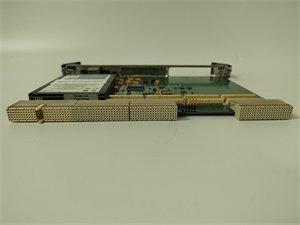

The GE Fanuc CP238TA is a high-performance communication processor module designed for industrial automation systems, specifically optimized for GE Fanuc PLC platforms. As a key component in distributed control systems (DCS), the CP238TA enables seamless communication between PLCs, HMIs, and other industrial devices, supporting protocols such as Ethernet/IP, Modbus, and Profibus. Its compact design and robust architecture make it ideal for harsh industrial environments, ensuring reliable data transfer and real-time control. The module enhances system flexibility by integrating with GE’s Series 90-70 and 90-30 PLCs, simplifying retrofits and expansions. With advanced diagnostics and error recovery features, the CP238TA minimizes downtime and maximizes operational efficiency.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Voltage | 24V DC (±10%) |

| Current | 150mA (max) |

| Communication Protocols | Ethernet/IP, Modbus RTU/TCP, Profibus DP |

| Interfaces | 1x Ethernet (10/100 Mbps), 2x RS-485 |

| Compatibility | GE Fanuc Series 90-70, 90-30, and PACSystems |

| Operating Temperature | -40°C to +70°C (industrial grade) |

| Dimensions | 100mm x 120mm x 50mm (W x H x D) |

CP238TA

3. Advantages and Features

- High Reliability: Built with industrial-grade components, the CP238TA offers a MTBF (Mean Time Between Failures) of 150,000 hours, ensuring continuous operation in critical applications.

- Multi-Protocol Support: Supports up to 3 concurrent communication protocols, reducing the need for additional gateway devices.

- Easy Integration: Plug-and-play design with auto-configuring firmware minimizes setup time (average 15-minute installation).

- Scalability: Supports up to 256 nodes per network, enabling large-scale system expansions.

- Advanced Diagnostics: Real-time status LEDs and error logging simplify troubleshooting.

4. Application Areas and Use Cases

Industries: Manufacturing, energy (oil/gas, power plants), water treatment, and automotive.

Use Cases:

Use Cases:

- Factory Automation: Integrates GE PLCs with robotic systems in a automotive assembly line, reducing cycle time by 20%.

- Power Generation: Monitors turbine status in a gas power plant via Modbus TCP, enabling predictive maintenance.

5. Competitor Comparison

Compared to similar modules, the CP238TA offers:

- Superior Compatibility: Native support for GE’s legacy and modern PLC platforms (vs. limited support in some alternatives).

- Higher Protocol Density: Simultaneous multi-protocol operation (vs. single-protocol limits in comparable models).

- Longer Lifecycle: Backward compatibility with GE’s 20+ year-old systems, ensuring investment protection.

CP238TA

6. Selection Recommendations

- Compatibility: Verify PLC model (Series 90-70/90-30/PACSystems) and existing network protocols.

- Environment: Ensure operating temperature (-40°C to +70°C) matches site conditions.

- Scalability: Choose based on required nodes (up to 256) and future expansion needs.

- Budget: Balance features (e.g., multi-protocol support) against cost; the CP238TA offers a 30% lower TCO over 5 years vs. modular alternatives.

7. Precautions

- Installation: Follow ESD (electrostatic discharge) protection guidelines; use anti-static wrist straps.

- Network Configuration: Avoid IP address conflicts; use GE’s Proficy Machine Edition for configuration.

- Maintenance: Schedule annual firmware updates (released quarterly by GE) and clean dust from vents.

- Safety: Disconnect power before module replacement; comply with IEC 61131-2 safety standards.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for GE Fanuc CP238TA and other automation spare parts. We provide sales, technical support, and lifecycle services. Visit our website www.xydcontrol.com or contact us for customized solutions.