Description

Product Overview

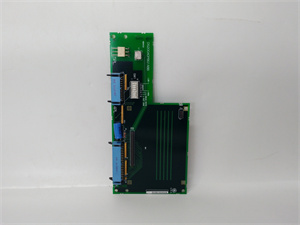

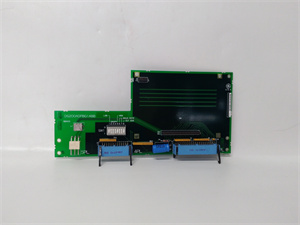

The GE DS200ADPBG1ABB is a high – performance Genius adapter board meticulously designed by General Electric for its Mark V turbine control system series. As a key component within this series, it serves as a crucial interface in industrial automation setups. This adapter board is engineered to connect and integrate various input and output (I/O) devices, facilitating seamless communication between sensors, actuators, and the central processing unit or controller.

Functionally, the DS200ADPBG1ABB enables the connection of a wide array of I/O devices to a compatible controller. It offers signal conditioning capabilities for different sensor and actuator types, ensuring accurate data transfer. By isolating the controller from electrical noise and transients, it significantly enhances the stability of the overall system. In industrial environments where reliability is paramount, this board simplifies system wiring and reduces installation complexity, making it an ideal choice for applications in power generation, oil and gas, and manufacturing industries.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200ADPBG1ABB |

| Manufacturer | General Electric |

| Product Type | Genius I/O Adapter Board |

| Series | Mark V |

| Power Requirements | +5 V DC, 6 A |

| Number of Relay Channels | 12 |

| Power Supply Voltage | 28 V DC |

| Mounting | DIN – rail mounting |

| Technology | Surface mount |

| Operating Temperature | -30 to + 65 °C |

| Size | 15.9 cm high x 17.8 cm |

| Connector Types | One 40 – pin connector and one 26 – pin connector |

| Number of Configuration Switches | One block of 8 switches |

DS200ADPBG1ABB

Main Features and Advantages

Versatile I/O Connectivity

The GE DS200ADPBG1ABB can interface with a diverse range of I/O devices. Whether it’s connecting temperature sensors, pressure sensors, or motors and solenoids, it provides the necessary connection points. This wide – ranging compatibility makes it suitable for complex industrial systems where multiple types of devices need to be integrated.

Signal Conditioning

It comes equipped with built – in signal conditioning circuits. These circuits perform tasks such as voltage level adjustment, filtering, and amplification. By ensuring that the signals between connected devices are precise and reliable, it minimizes the risk of errors in data exchange, which is crucial for accurate control in industrial processes.

Noise Isolation

With its ability to isolate the controller from electrical noise and transients, the DS200ADPBG1ABB enhances system stability. In industrial settings filled with electromagnetic interference, this isolation feature protects the integrity of the signals being transmitted, reducing the likelihood of system malfunctions due to external electrical disturbances.

Configuration Flexibility

Featuring one block of 8 switches for board configuration, along with a 40 – pin and a 26 – pin connector, the board offers flexibility. Users can customize its operation to suit specific application requirements. The manually – moveable hardware jumpers further add to this customization, allowing for supreme adaptability in different industrial scenarios.

Application Field

Power Generation

In power plants, the GE DS200ADPBG1ABB is used to interface with sensors and actuators in turbine control systems. For example, it can connect to sensors that monitor the temperature and pressure of steam in a steam turbine. By processing and relaying these signals to the control system, it enables precise control of the turbine’s operation, ensuring efficient power generation. In gas turbines, it can be linked to actuators that adjust the fuel supply, optimizing the combustion process for better performance.

Oil and Gas Industry

Within refineries and oil platforms, this adapter board plays a vital role. In a refinery, it can connect to a variety of I/O devices such as level sensors in storage tanks, flow meters in pipelines, and control valves. It processes the signals from these devices and sends them to the central control system, which then manages the refining process. On an oil platform, it interfaces with sensors that detect the presence of gas leaks or the status of safety valves, contributing to a safe and efficient operation.

Manufacturing

In manufacturing plants, the DS200ADPBG1ABB is used to integrate different components of production lines. It can connect proximity sensors on conveyor belts to detect the presence of products, and then relay this information to the control system to adjust the speed of the conveyor. In robotic assembly lines, it interfaces with limit switches on robotic arms, providing real – time feedback on the arm’s position to the control system for accurate movement and assembly operations.

DS200ADPBG1ABB

Related Products

GE DS200ADPBG1A

Similar to the DS200ADPBG1ABB, it is also a Genius adapter board within the Mark V series. The main difference might lie in certain revisions or specific component configurations, but both serve the purpose of interfacing I/O devices in industrial control systems.

GE DS200 series boards

The DS200ADPBG1ABB is part of the DS200 series. Other boards in this series, like voltage feedback scaling boards, share the same platform and might have related functions. They are designed to work in tandem within the Mark V turbine control system, each contributing to different aspects of system operation.

GE Mark V series components

Components such as control modules and power distribution units in the Mark V series work in conjunction with the DS200ADPBG1ABB. The adapter board provides the necessary I/O connectivity, while these other components handle control and power management functions, together forming a comprehensive industrial control solution.

GE IC693MDL646

This is a discrete input module from GE. Although it has a different function (focusing on discrete input signal handling) compared to the DS200ADPBG1ABB, in a complex industrial automation system, they can be used together. The IC693MDL646 can provide input signals, which the DS200ADPBG1ABB may then process and route to the appropriate control elements.

GE IC697ALG230

An analog input module, it can work in parallel with the DS200ADPBG1ABB in industrial setups. While the adapter board focuses on I/O device integration, the IC697ALG230 is responsible for handling analog input signals. In a system where both analog and digital signals need to be processed and integrated, these two components can complement each other.

Installation and Maintenance

Pre – installation preparation: Before installing the GE DS200ADPBG1ABB, ensure that the power to the relevant industrial control system is switched off to avoid electrical hazards. Thoroughly inspect the board for any visible signs of damage during transit, such as scratches on the circuit board or bent connectors. Familiarize yourself with the installation manual provided by GE, which includes details about the board’s mounting requirements. Since it uses DIN – rail mounting, verify that the DIN – rail is in good condition and properly installed. Also, check the compatibility of the board with other components in the Mark V system, including the types of I/O devices it will be connected to.

Maintenance recommendations: Regularly clean the DS200ADPBG1ABB to remove dust and debris, as these can accumulate over time and affect its performance, especially in terms of heat dissipation. Periodically check the connection status of the 40 – pin and 26 – pin connectors to ensure they are secure. Monitor the board’s operating temperature to ensure it remains within the specified -30 to + 65 °C range. If any abnormal behavior is detected, such as incorrect signal readings or system malfunctions, refer to the troubleshooting guide in the product manual. Keep spare parts, such as replacement switches and connectors, on hand to quickly address any potential failures.

Product Guarantee

General Electric stands firmly behind the quality of the GE DS200ADPBG1ABB. The product comes with a comprehensive quality assurance program. GE guarantees that the board is free from manufacturing defects for a specified period. In case of any defects during this warranty period, GE will provide repair or replacement services at no additional cost to the customer. Their global network of technical support teams is available around the clock to offer prompt assistance for installation guidance, troubleshooting, and any other technical issues. This reflects GE’s confidence in the reliability and performance of the DS200ADPBG1ABB, ensuring customers can rely on it for their critical industrial applications.