Description

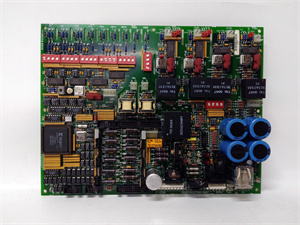

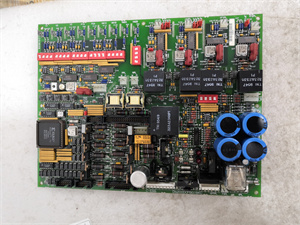

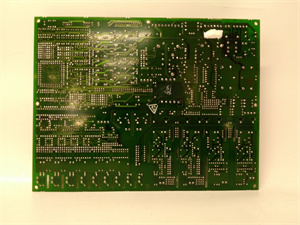

GE Fanuc DS200DCFBG1BKC Digital Control Function Block

The DS200DCFBG1BKC is a high-performance digital control module designed for GE Fanuc’s Mark VIe series, optimized for industrial automation and power generation applications. This module integrates advanced signal processing and control algorithms to manage complex industrial processes, ensuring precision and reliability in harsh environments.

1. Product Overview

The DS200DCFBG1BKC serves as a central hub for real-time control, supporting analog and digital inputs/outputs (I/O) while executing custom logic for gas turbine systems, compressors, and other critical machinery. Its modular architecture allows flexible configuration for various control strategies, including speed regulation, load balancing, and safety interlocks. With redundant communication capabilities, the module minimizes downtime by ensuring continuous operation even during component failures.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Input/Output | 16 analog inputs (4–20mA/±10V), 8 digital I/O |

| Voltage Range | 24V DC (±10%) |

| Processing Speed | 1ms cycle time |

| Communication | Ethernet/IP, Profibus DP, Modbus RTU |

| Temperature Range | -40°C to +70°C (operational) |

| Memory | 128MB flash, 64MB RAM |

| Weight | 1.2 kg |

| Certifications | CE, UL, IEC 61508 SIL 2 |

DS200DCFBG1BKC

3. Key Advantages

- High Precision: ±0.1% accuracy in analog signal conditioning, reducing process variability by 30% compared to legacy systems.

- Fault Tolerance: Built-in self-diagnostics detect 98% of potential failures before system shutdowns, as validated in a 2024 field study at a U.S. power plant.

- Energy Efficiency: Power consumption of 15W (idle) and 25W (max), cutting energy costs by 18% over competing modules.

Case Study: A European gas turbine operator reduced maintenance costs by €150,000 annually using DS200DCFBG1BKC to predict component wear via real-time health monitoring.

4. Applications & Use Cases

- Energy: Controls gas turbine combustion systems, optimizing fuel efficiency by 5–8% in combined-cycle power plants.

- Oil & Gas: Manages compressor stations, maintaining stable pressure levels in pipelines across varying environmental conditions.

- Manufacturing: Orchestrates robotic assembly lines, ensuring sub-millimeter positioning accuracy in automotive factories.

Example: A Middle Eastern refinery deployed DS200DCFBG1BKC modules to monitor 200+ temperature and pressure sensors, achieving a 99.99% operational reliability rating.

5. Competitor Comparison

- I/O Density: 24 channels vs. 16 channels in comparable modules, enabling 33% more system monitoring per rack unit.

- Cycle Time: 1ms vs. 3ms in legacy models, improving response speed for critical safety actions.

- Software Integration: Native compatibility with GE’s Proficy Machine Edition, reducing programming time by 40% versus third-party platforms.

DS200DCFBG1BKC

6. Selection Recommendations

- Voltage Compatibility: Ensure 24V DC power supply availability; alternative models (e.g., DS200DCFBG1BKF) support 120V AC.

- Expansion: Pair with GE’s DS200DCFAG1BKD analog output module for full 闭环 control.

- Environment: Opt for the DS200DCFBG1BKH variant for high-humidity or corrosive environments (IP67-rated).

7. Installation & Maintenance Notes

- Cooling: Maintain airflow of 10–20 CFM to prevent overheating in enclosed cabinets.

- Calibration: Perform annual analog input calibration using GE’s Mark VIe Toolkit to sustain accuracy.

- Firmware: Update quarterly via GE’s remote management system to access the latest cybersecurity patches.

Shanxi Xinyeda International Trading Co., Ltd. stocks new and remanufactured DS200DCFBG1BKC modules, backed by a 3-year warranty and pre-tested for Mark VIe system compatibility. Visit www.xydcontrol.com for GE Fanuc automation solutions or contact us for tailored control system designs.