Description

Product Overview

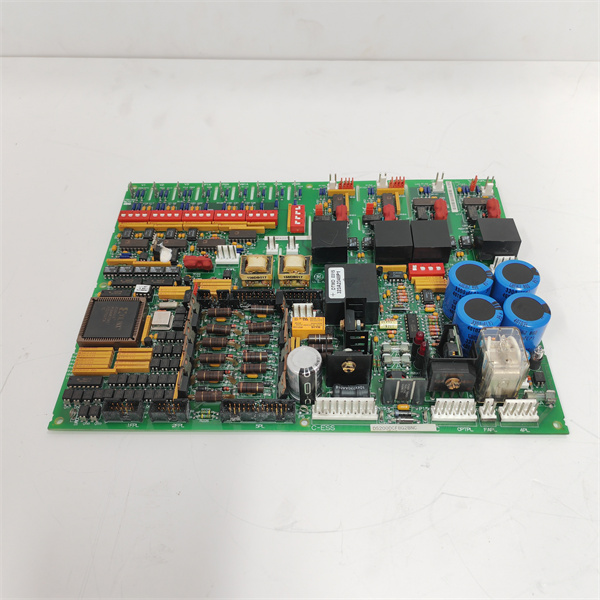

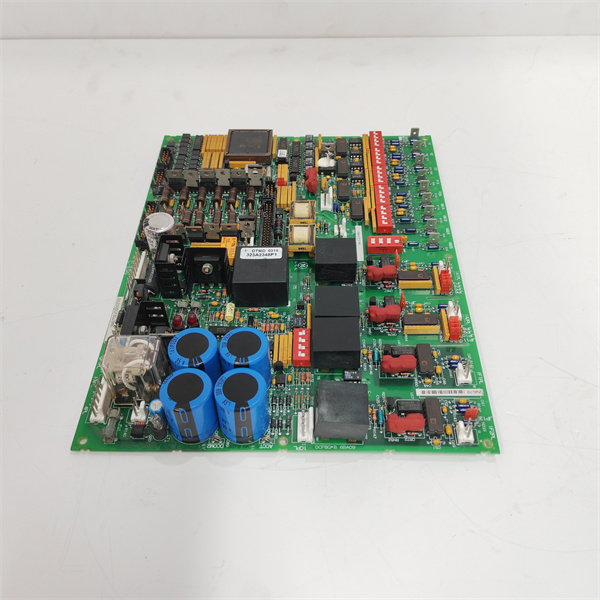

The GE DS200DCFBG2BNC is a DC feedback board that was specifically crafted for GE’s esteemed Mark V series. The Mark V system, part of GE’s long – standing and successful Speedtronic gas and steam turbine management lineage, which has seen multiple iterations since the late 1960s, is renowned for its reliability in industrial turbine control. The DS200DCFBG2BNC plays a pivotal role within this system.

Functionally, it is responsible for sending and receiving crucial input and output signals, which are essential for the accurate operation and control of the turbines. This board is equipped with a variety of components such as transformers, oscillating chips, a relay, and numerous resistor network arrays. These components work in unison to ensure smooth signal processing and power supply management within the Mark V system. In the overall industrial automation landscape, the GE DS200DCFBG2BNC is positioned as a reliable and integral part of turbine control setups, enhancing the performance and stability of gas and steam turbine operations.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200DCFBG2BNC |

| Manufacturer | GE |

| Product Type | DC Feedback Board |

| Connector Type | 18 plug connectors and 9 stab connectors |

| Dip Switches | 7, used for selecting ac line voltage and voltage for specific circuits |

| Test Points | 5 tp test points for checking voltage signals, board common, and acct signal status |

| Indicators | 2 LED lights and 1 neon indicator to show fuse state |

| Jumpers | 12 |

| Fuses | 3, for power supply protection |

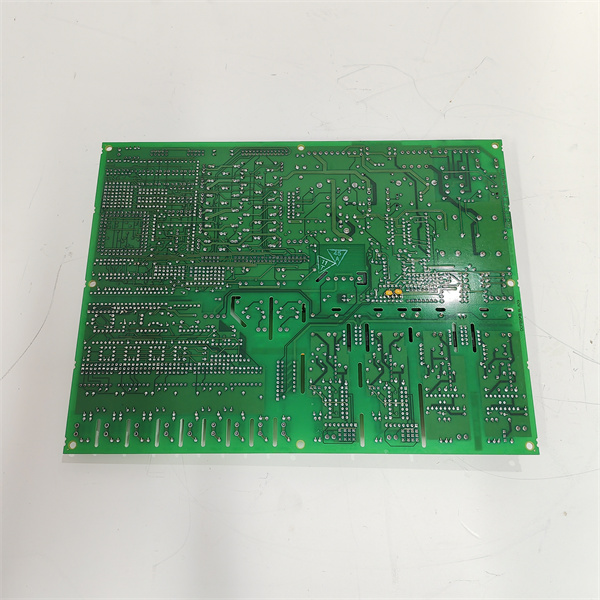

| Component Types | 7 transformers, oscillating chips, a relay, over 50 resistor network arrays, heat sinks, various integrated circuits, capacitors, and resistors (including CCR and metal – film resistors) |

| Revision Quantity | 3 revisions |

| Backwards – compatibility | First two revisions are backwards – compatible |

| Assembly Type | Normal assembly |

| Weight | Approximately 1.36 kg (3 lbs) |

DS200DCFBG2BNC MRP433745

Main Features and Advantages

Reliable Signal Handling

The GE DS200DCFBG2BNC is designed with a comprehensive set of connectors – 18 plug connectors and 9 stab connectors. This allows for efficient sending and receiving of input and output signals. The stab connectors, located in the upper – left corner of the board and labeled distinctly, and the various plug connectors across the board ensure a stable connection for signal transfer. In a gas turbine control system, accurate signal handling is crucial for maintaining the correct speed and power output, and the DS200DCFBG2BNC excels in this regard.

Protective Features

With 3 fuses dedicated to power supply protection, the board is safeguarded against potential electrical faults. If any of these fuses blow, the 2 LED lights and 1 neon indicator will light up, immediately notifying technicians of the issue. This not only helps in quick troubleshooting but also prevents further damage to the board and the overall turbine control system. In industrial environments where power fluctuations can occur, these protective features are invaluable.

Component Diversity

Featuring a wide range of components such as 7 transformers, oscillating chips, a relay, and over 50 resistor network arrays, the DS200DCFBG2BNC is well – equipped to handle complex signal processing and power management tasks. The combination of different component types allows for fine – tuned control and adaptability within the Mark V system, making it suitable for various operating conditions in gas and steam turbine applications.

Application Field

The GE DS200DCFBG2BNC finds its primary applications in gas and steam turbine control systems. In power generation plants, it is used to manage and regulate the operation of turbines. For instance, in a coal – fired power plant with steam turbines, the board plays a role in ensuring the turbines operate at optimal speeds. By accurately handling feedback signals related to turbine speed, temperature, and pressure, it enables the control system to make necessary adjustments.

In industrial manufacturing facilities that use gas turbines for powering large – scale machinery, the DS200DCFBG2BNC helps in maintaining the stability of the power supply. It ensures that the turbines can respond quickly to changes in power demand, providing a consistent power source for the manufacturing processes. Additionally, in oil and gas refineries, where gas turbines are used for compression and pumping operations, the board contributes to the efficient and reliable operation of these critical processes.

DS200DCFBG2BNC MRP433745

Related Products

- DS200DCFBG1BNC: A power supply board in the same Mark V series as the DS200DCFBG2BNC. It likely has similar functions but may differ in terms of specific signal handling capabilities or component configurations, offering an alternative option for certain applications within the Mark V system.

- DS200DSFBG2: Another board in the Mark V series. It may be involved in different aspects of the system, perhaps focusing more on digital signal processing compared to the DC feedback function of the DS200DCFBG2BNC, but still part of the overall ecosystem for turbine control.

- GE Mark VIe Control System Components: The Mark VIe is an evolution of the Mark V system. Components from this series, such as certain I/O modules or controllers, can work in tandem with the DS200DCFBG2BNC in modernized or upgraded turbine control setups, providing enhanced functionality and compatibility.

- DS200DSPCH1: This board within the Mark V series may have different processing or control functions. It could be used in combination with the DS200DCFBG2BNC to achieve a more comprehensive control solution for complex turbine operations.

- GE Speedtronic Gas Turbine Sensors: These sensors provide real – time data on parameters like temperature, pressure, and speed. The DS200DCFBG2BNC uses the data from these sensors to perform its feedback and control functions, making them essential related products in the overall turbine control system.

Installation and Maintenance

Pre – installation preparation: Before installing the GE DS200DCFBG2BNC, ensure that the power to the Mark V system is completely turned off to avoid any electrical hazards. Thoroughly inspect the board for any visible signs of damage, such as bent connectors or cracked components, during transit. Familiarize yourself with the layout of the Mark V system where it will be installed and make sure the installation location is clean and free from dust and debris. When installing, carefully align the board’s connectors with the corresponding ports in the system and secure it in place using the appropriate mounting hardware.

Maintenance recommendations: Regularly check the DS200DCFBG2BNC for any loose connections. The connectors should be inspected to ensure they are firmly attached. Monitor the status indicators (the 2 LED lights and 1 neon indicator) frequently. If any of the fuses have blown, indicated by the lights, replace them with the correct – rated fuses as per the product manual. Keep the board clean by gently removing dust with a soft, dry brush. In case of any abnormal behavior in the turbine control system related to DC feedback, start by troubleshooting the DS200DCFBG2BNC using the diagnostic tools and procedures provided in the GE documentation.

Product Guarantee

GE stands firmly behind the quality of the DS200DCFBG2BNC. The board is manufactured under strict quality – control measures to meet high – standard industrial requirements. In case of any defects in materials or workmanship, GE offers a reliable after – sales service. Their technical support team is available to provide remote diagnostic services and, if necessary, on – site assistance. GE typically provides a warranty period during which, if the DS200DCFBG2BNC fails due to quality – related issues, they will repair or replace the board free of charge. This reflects GE’s confidence in the product’s reliability and their commitment to ensuring customer satisfaction in industrial automation applications.