Description

Product Overview

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

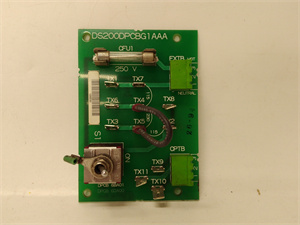

| Product Model | DS200DPCBG1AAA |

| Manufacturer | GE |

| Product Type | Contact Input Group Isolation Terminal Board |

| Number of Inputs | 24 (dry contacts) |

| Nominal Voltage | 24 V dc |

| Input Voltage Range | For H1: 100 – 145 V dc (float 125 V dc for turbine – controlled power supply); H2 and H3 use lower voltages as per spec sheet |

| Input Current per Point | N/A (not specified in provided data) |

| Input Frequency | N/A (not specified in provided data) |

| Typical Input Impedance | N/A (not specified in provided data) |

| On – state Voltage | N/A (not specified in provided data) |

| Off – state Voltage | N/A (not specified in provided data) |

| On – state Current | N/A (not specified in provided data) |

| Off – state Current | N/A (not specified in provided data) |

| Response Time (On) | N/A (not specified in provided data) |

| Response Time (Off) | N/A (not specified in provided data) |

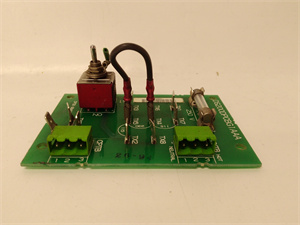

| Terminal Block Capacity | Can accommodate wires up to #12 AWG |

| Isolation Type | Group isolation |

| Noise Reduction | Equipped with noise – reduction circuits for contact inputs to protect against surges and high – frequency noise |

| Application Compatibility | Supports simplex and TMR (Triple Modular Redundancy) applications; works with VTCC/VCRC; used with Mark VI, Mark VIe, or Mark VIeS systems |

DS200DPCBG1AAA

Main Features and Advantages

Group Isolation: It features group isolation, which effectively separates different input groups. This isolation is crucial in preventing electrical interference between various input signals, ensuring accurate data transmission and reliable operation of the control system.

Noise – Reduction Capability: The board is equipped with dedicated noise – reduction circuits for contact inputs. These circuits protect against both surges and high – frequency noise, enhancing the stability and integrity of the input signals. This is particularly important in industrial environments where electrical noise can be a common issue.

Versatile Application Support: It is compatible with both simplex and TMR applications, making it suitable for a wide range of industrial control requirements. Whether in a basic single – processor system or a more complex redundant setup, the DS200DPCBG1AAA can effectively perform its function. It also works in tandem with VTCC/VCRC and is well – integrated with Mark VI, Mark VIe, or Mark VIeS systems, offering flexibility in system design.

Easy Maintenance: The two 24 – point barrier – type, removable wiring terminal blocks make maintenance and troubleshooting a breeze. Technicians can easily remove these blocks for inspection or replacement without having to deal with complex wiring arrangements. Each block can accommodate wires up to #12 AWG, providing flexibility in wiring choices.

Application Field

Power Generation: In power plants, the GE DS200DPCBG1AAA is used to connect and manage dry contact inputs from various sensors. These sensors can monitor the status of equipment such as circuit breakers, relays, and valves. By accurately relaying this information to the control system, it helps in ensuring the safe and efficient operation of power – generating equipment. For example, it can detect when a generator’s cooling system has a fault or when a switchgear component needs maintenance.

Manufacturing: In manufacturing facilities, the board interfaces with sensors on production lines. It can receive signals from limit switches that indicate the position of conveyor belts or the presence of products at specific stages of the manufacturing process. This enables the automation system to control the production flow, prevent jams, and optimize the overall manufacturing efficiency.

Oil and Gas Industry: In oil refineries and gas processing plants, the DS200DPCBG1AAA is used to connect sensors that monitor parameters like pressure, temperature, and flow rates. It plays a crucial role in maintaining the integrity of the production process by providing real – time data on the status of various equipment. For instance, it can detect abnormal pressure changes in pipelines or the malfunction of a gas compressor, allowing for timely intervention.

DS200DPCBG1AAA

Related Products

IS200STCIH2A: A multi – PCB populated with SMD components and connectors. While it has a different form factor and function in some aspects, in a larger industrial control system, it may interact with the DS200DPCBG1AAA as part of a comprehensive input – output management setup.

IC670MDL240J: A digital input module by GE. Although it has a different input configuration and voltage handling capabilities, in an industrial automation system, it may be used in conjunction with the DS200DPCBG1AAA to manage different types of digital input signals, expanding the overall input – handling capacity of the system.

VMIPMC – 5565: An optic reflective memory card. In a complex industrial setup, it may communicate with the DS200DPCBG1AAA to transfer input data for further processing or storage, as part of an integrated data – sharing and control ecosystem.

GE IS200WREAS1ADB: A turbine – related control board. In power generation or industrial applications involving turbines, the DS200DPCBG1AAA may work in tandem with this board, with the former handling contact inputs related to the turbine’s auxiliary systems and the latter being more focused on turbine protection and emergency trip functions.

Installation and Maintenance

Maintenance recommendations: Regularly check the connection of the terminal blocks to ensure that the wires are secure and not loose. Over time, vibrations in the industrial environment can cause connections to come loose. Monitor the performance of the board by checking for any abnormal readings or error messages in the control system related to the input signals. If any issues are detected, refer to the product manual for troubleshooting steps. Periodically clean the board using a static – free brush to remove dust and debris, as these can also impact the electrical performance of the components. In case of a component failure, replace it with a compatible part as per the manufacturer’s recommendations.