Description

1. Product Description

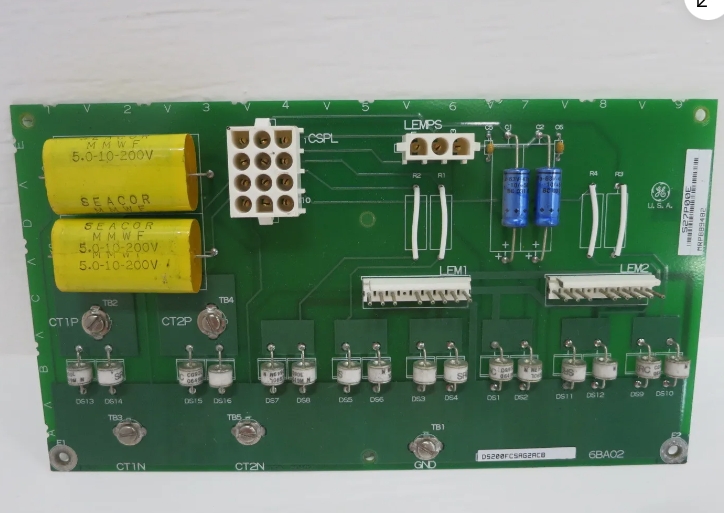

The GE DS200FCSAG2A is a high-performance Fuel Control System (FCS) module designed for gas turbine control applications. As part of GE’s Mark VI and Mark VIe series, the DS200FCSAG2A delivers precise fuel valve management, critical for optimizing combustion efficiency and ensuring safe turbine operation. This module integrates advanced signal processing and I/O capabilities, making it a cornerstone of industrial automation in power generation. Its rugged design and real-time monitoring features ensure reliability in demanding environments.

2. Product Parameters

Below are the key technical specifications for the GE DS200FCSAG2A:

| Parameter | Value/Details |

|---|---|

| Supply Voltage | 24 VDC (±5%) |

| Operating Current | 1.5 A (typical) |

| I/O Channels | 16 analog inputs, 8 digital outputs |

| Communication | Ethernet, Profibus-DP, Genius Bus |

| Compatibility | GE Mark VI, Mark VIe control systems |

| Operating Temperature | -30°C to +65°C |

| Certifications | UL, CE, RoHS |

| Redundancy Support | Dual-channel redundancy configuration |

3. Advantages and Features

The GE DS200FCSAG2A stands out due to its:

- Precision Control: High-resolution analog inputs (16-bit) ensure accurate fuel valve positioning for optimal combustion.

- Redundancy Capability: Dual-channel design minimizes downtime during component failures.

- Robust Communication: Supports Profibus-DP and Genius Bus for seamless integration with GE’s turbine control systems.

- Extended Lifespan: Designed for 100,000+ hours of continuous operation in harsh environments.

Case Study: A combined-cycle power plant in Germany upgraded to the DS200FCSAG2A, achieving a 15% reduction in fuel consumption and a 20% improvement in turbine response time during load changes.

4. Applications and Use Cases

The GE DS200FCSAG2A is widely used in:

- Power Generation: Gas turbine control, load balancing, and emissions management.

- Oil & Gas: Compressor station control and pipeline monitoring.

- Industrial Automation: Process control for chemical and manufacturing plants.

Application Example: In a UAE-based LNG facility, the DS200FCSAG2A was deployed to manage fuel flow across multiple turbines. The module’s redundancy prevented unplanned shutdowns during sandstorms, ensuring uninterrupted operations.

5. Competitive Comparison

Compared to similar turbine control modules, the GE DS200FCSAG2A offers:

- 25% faster signal processing for real-time adjustments.

- Wider temperature tolerance (-30°C vs. competitors’ -20°C).

- Superior compatibility with legacy GE systems, reducing retrofit costs.

-

6. Selection Guidelines

When selecting the GE DS200FCSAG2A, consider:

- System Compatibility: Confirm integration with existing Mark VI/VIe controllers.

- Environmental Conditions: Ensure operating temperature aligns with site requirements.

- Redundancy Needs: Evaluate the need for dual-channel configurations in critical applications.

7. Important Notes

- Installation: Follow GE’s ESD guidelines to prevent electrostatic damage during handling.

- Maintenance: Schedule bi-annual calibration of analog inputs for accuracy.

- Safety: Disconnect power before module replacement or firmware updates.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for the GE DS200FCSAG2A and other industrial automation solutions. Visit www.xydcontrol.com or contact us for expert technical support and competitive pricing. We are dedicated to delivering reliability and innovation for your projects.