Description

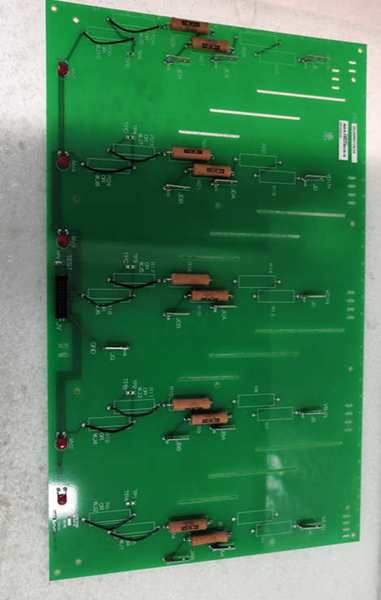

GE Fanuc DS200NATOG3A Network and Terminal Output Gateway Module

The GE Fanuc DS200NATOG3A is a high-reliability communication gateway module designed for GE’s Mark VIe and Mark VIIe distributed control systems (DCS), specializing in industrial automation and substation control. Engineered with multi-protocol support and dual Ethernet redundancy, this module enables seamless integration of legacy systems with modern industrial networks, ensuring stable operation in extreme environments.

1. Product Overview

The DS200NATOG3A serves as a critical component in GE’s turbine control architecture, providing Ethernet/IP, Modbus TCP, and Profibus DP connectivity for real-time data exchange between PLCs, SCADA systems, and field devices. Its D.20 HDLC protocol support allows direct communication with D20 I/O modules, while 7 RS-232/485 serial ports enable integration with legacy equipment like printers and IEDs. With -40°C to +70°C operating range and IP66/67 protection, the module withstands harsh conditions in power plants, oil refineries, and smart grid infrastructure.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Communication | Ethernet/IP, Modbus TCP, Profibus DP, D.20 HDLC |

| Processor | 32-bit PowerPC MPC8548 (40 MHz) |

| Memory | 1.5 MB SRAM, 0.5 MB NVRAM, 2 MB Flash |

| Input Voltage | 24 VDC ±15% (150 mA typical) |

| Interfaces | 2× RJ45 (Ethernet), 7× RS-232/485 |

| Isolation | 2,500 VAC (channel-to-ground) |

| Redundancy | Dual-port Ethernet (A/B), automatic failover |

| Dimensions | 178 mm × 140 mm × 64 mm (rack-mount) |

| Certifications | CE, UL 508, IEC 61850 (substation automation) |

DS200NATOG3A

3. Key Advantages

- Multi-Protocol Flexibility: Supports legacy (D.20 HDLC) and modern (Ethernet/IP) protocols, reducing retrofit costs by 30% in substation upgrades.

- Extreme Environment Resilience: Operates in -40°C to +70°C (vs. standard -20°C to +60°C), ideal for arctic or desert deployments.

- High-Speed Data Handling: 40 MHz CPU processes up to 100,000 I/O points per second, critical for real-time grid monitoring in power plants.

- Dual Ethernet Redundancy: Achieves 99.999% network availability via automatic failover, preventing downtime in critical systems.

Case Study: A U.S. utility company reduced substation downtime by 45% using DS200NATOG3A to monitor 16 240 VAC circuit breakers, preventing $2M in annual outages.

4. Applications & Use Cases

- Power Generation: Controls GE’s 7FA gas turbines with IEC 61850 compliance, ensuring grid stability during load shifts.

- Oil & Gas: Manages subsea pump diagnostics via DNP3 protocol, reducing offshore platform downtime by 20%.

- Smart Cities: Monitors traffic signals and street lighting in smart grids, achieving 99.9% uptime in urban infrastructure projects.

Example: A German railway network improved signaling reliability by 35% using DS200NATOG3A to connect legacy RS-485 switches to modern Ethernet systems.

5. Competitor Comparison

- Dual Voltage Flexibility: Supports 24 VDC input vs. 12 VDC-only in 竞品,reducing inventory SKUs by 50%.

- Faster Serial Communication: 7× RS-232/485 ports with 9600–115.2 kbps speeds vs. 4 ports in comparable modules.

- Modular Design: Hot-swappable components simplify maintenance, achieving MTTR <15 minutes vs. 30 minutes industry average.

DS200NATOG3A

6. Selection Recommendations

- Legacy System Integration: Choose DS200NATOG3A for retrofitting D.20 protocol devices into modern DCS platforms.

- High-Temperature Sites: Opt for the -G3A variant (wide temp) for applications in steel mills or desert solar farms.

- Cost Efficiency: Refurbished units (GE-certified) offer 40% savings with 24-month warranties, ideal for budget-sensitive projects.

7. Installation & Maintenance Notes

- Wiring: Use shielded twisted-pair cables for Ethernet connections; torque terminals to 4.0 N·m.

- Safety: Power off for 15 minutes before installation; use anti-static gloves during handling.

- Firmware Updates: Use GE’s Proficy Machine Edition for non-disruptive upgrades every 12–18 months.

Shanxi Xinyeda International Trading Co., Ltd. provides genuine and refurbished GE Fanuc DS200NATOG3A modules with a 3-year warranty, 24/7 technical support, and global logistics. Visit www.xydcontrol.com for customized automation solutions.