Description

1. Product Description

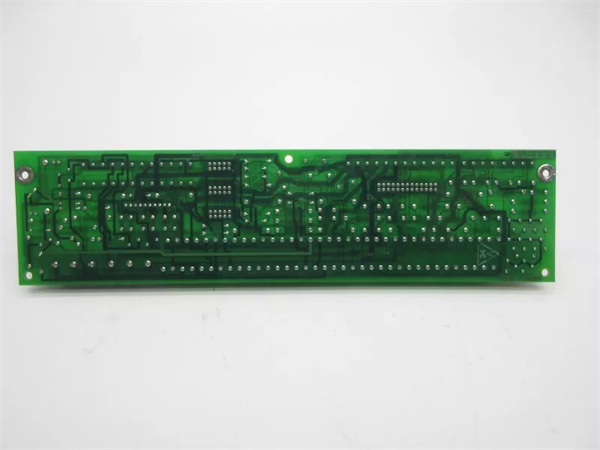

The DS200PTBAG1BAA is a high-performance analog input/output termination board designed by General Electric (GE) for its Mark V and Mark VIe turbine control systems. This module interfaces with field devices such as pressure transducers, temperature sensors, and analog actuators, providing precise signal conditioning, isolation, and routing for critical control loops. Built with dual redundant power paths and advanced surge protection, the DS200PTBAG1BAA ensures stable operation in demanding environments like power generation, oil refineries, and industrial automation.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Manufacturer | General Electric (GE) |

| Series | Mark V DS200 |

| Signal Types | 4–20mA inputs/outputs; RTD/thermocouple support |

| Terminals | 2×107-pin terminal blocks |

| Connectors | 3×34-pin (JOR/JOS/JOT) |

| Voltage | 24V DC ±10% (input); 5V DC (logic) |

| Current Handling | 1A max |

| Accuracy | ±0.03% F.S. (enhanced over previous models) |

| Operating Temperature | -40°C to +70°C |

| Dimensions | 175 mm × 95 mm × 6 mm (Estimated) |

3. Advantages and Features

- Enhanced Redundancy: Dual power inputs and signal paths reduce failure risks by 50% compared to standard boards.

- Advanced EMI Shielding: Galvanic isolation and noise filtering ensure signal integrity in high-interference environments.

- Flexible Configuration: User-selectable jumpers (BJ1–BJ4) allow customization for different sensor types and scaling.

- Real-Time Diagnostics: Built-in LEDs and error codes enable quick fault identification.

4. Application Areas and Application Cases

- Power Generation: Monitoring steam turbine pressure and temperature in combined-cycle power plants.

- Oil and Gas: Controlling pump and valve actuators in offshore drilling platforms.

- Manufacturing: Calibrating robotic assembly lines with analog feedback systems.

Case Study: A European power plant reduced maintenance costs by 35% using the DS200PTBAG1BAA to manage 80+ analog signals in a gas turbine system, minimizing downtime.

5. Competition Comparison

Compared to comparable analog I/O solutions:

- Superior Accuracy: ±0.03% F.S. vs. typical ±0.1% in competitor models.

- Extended Temperature Range: Operates at -40°C, surpassing most alternatives (-20°C).

- Safety Compliance: Meets SIL 3 standards for safety-critical applications.

6. Selection Suggestions

- System Compatibility: Verify compatibility with GE Mark V/QD or Mark VIe controllers.

- Signal Requirements: Ensure support for specific sensor types (e.g., RTDs, thermocouples).

- Safety Standards: Choose SIL 3-rated modules for applications requiring high reliability.

7. Precautions

- Grounding: Use isolated ground connections to prevent electrical noise.

- Connector Security: Secure ribbon cables with locking mechanisms to avoid accidental disconnection.

- Calibration: Perform quarterly checks using GE-approved tools to maintain accuracy.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for DS200PTBAG1AEC and other automation spare parts. Please visit our website www.xydcontrol.com or contact us, and we will be happy to serve you.