Description

Product Overview

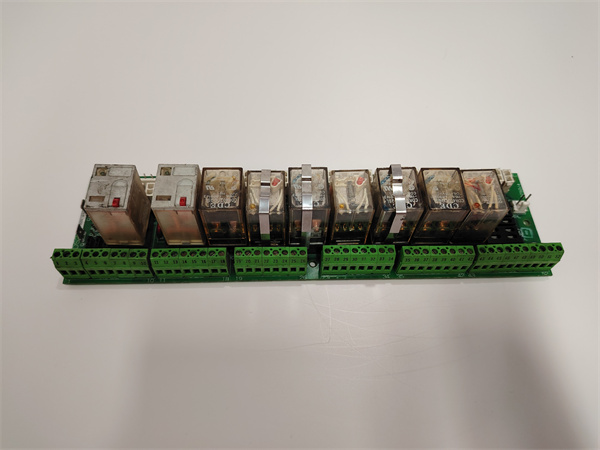

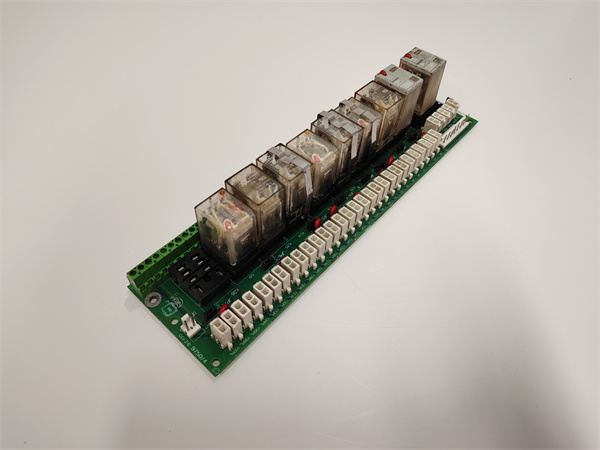

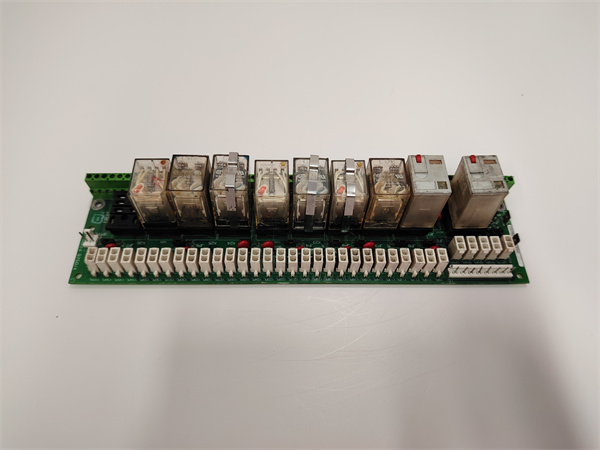

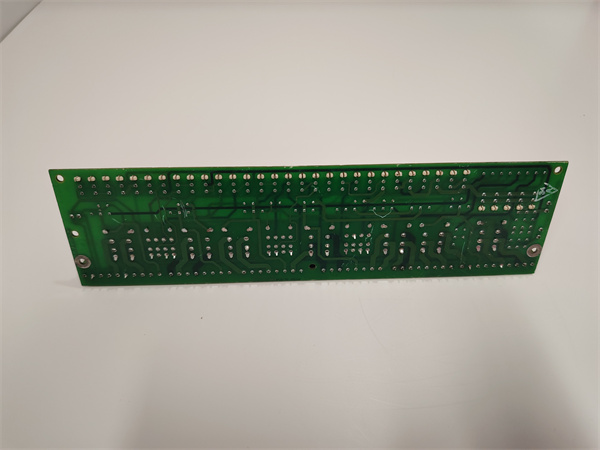

The GE DS200RTBAG3AHC is a pivotal relay terminal board engineered by General Electric for the esteemed Mark V turbine control system series. In the complex realm of industrial automation, it serves as a crucial linchpin, facilitating seamless control and management of various turbine – driven automated systems, including those powered by wind, steam, and gas turbines. This board, often installed within a drive cabinet, is designed to offer high – level functionality. It features 10 relays that provide remarkable flexibility, as they can be directly actuated by guide relays or remotely controlled by the user. With 52 endpoints dedicated to input/output (I/O) operations, the GE DS200RTBAG3AHC efficiently handles the transfer of signals, ensuring precise control within the automation setup. For instance, a set of these endpoints is dedicated to the C – shaped contact of relay K20, with distinct endpoints for the normally open, common, and normally closed positions. Two plug – in connectors, CPH (positive power) and CPN (negative power), further enhance its functionality by supplying a convenient pluggable circuit control power supply.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|

Product Model

|

DS200RTBAG3AHC

|

|

Manufacturer

|

General Electric

|

|

Product Type

|

Relay Terminal Board

|

|

Series

|

Mark V

|

|

Number of Relays

|

10

|

|

Relay Driving Method

|

Directly by pilot relays or remotely by user

|

|

Number of Endpoints for I/O

|

52

|

|

Connector Types

|

CPH (positive power) and CPN (negative power) plug – in connectors

|

|

Input Voltage

|

12 – 24 VDC

|

|

Output Voltage

|

10 – 20 VAC

|

|

Output Current

|

100 mA

|

|

Operating Temperature Range

|

– 40 °C to + 70 °C

|

|

Dimensions

|

100 x 50 x 25 mm

|

|

Weight

|

0.5 kg

|

|

PCD Coating

|

Normal coating

|

|

Functional Revision

|

1A, 2H

|

|

Artwork Revision

|

C

|

|

Group in Mark V Series

|

G3

|

|

Coil Voltage of G3 RTBA

|

115 VAC

|

DS200RTBAG3AHC

Main Features and Advantages

Flexible Relay Configuration: The GE DS200RTBAG3AHC offers the versatility of having 10 relays that can be controlled in two distinct ways. Whether it’s direct actuation from pilot relays or remote control by the user, this flexibility allows for customized control strategies in different industrial scenarios. For example, in a power generation plant, operators can remotely adjust the relays’ settings based on real – time power demands.

Abundant I/O Endpoints: With 52 endpoints for I/O purposes, the board can handle a large number of signal connections. This is particularly beneficial in complex industrial systems where multiple sensors and actuators need to be integrated. The dedicated endpoints for relay K20’s C – shaped contact ensure accurate signal handling for specific control functions.

Convenient Power Connectors: The inclusion of CPH and CPN plug – in connectors simplifies the power supply connection. These connectors provide a reliable and easily accessible way to supply power for circuit control. The pluggable circuits, such as C1PL to C5PL and Y9PL to Y37PL, offer further flexibility in power distribution.

Robust Design: Built to withstand harsh industrial environments, the board has an operating temperature range from – 40 °C to + 70 °C. This wide temperature tolerance makes it suitable for use in various geographical locations and industrial settings, from cold outdoor wind farms to hot and humid industrial plants.

Application Field

Power Generation: In power plants, the GE DS200RTBAG3AHC is extensively used in turbine control systems. For gas turbines, it helps regulate the fuel supply and combustion process by controlling the relays based on input signals from sensors monitoring temperature, pressure, and rotational speed. In steam turbines, it manages the operation of valves and pumps, ensuring efficient steam generation and power production.

Industrial Manufacturing: In manufacturing facilities, this board can be found in automated production lines. For example, in a factory producing automotive parts, it controls the movement of conveyor belts, robotic arms, and other machinery. The relays on the GE DS200RTBAG3AHC can be programmed to start or stop equipment at specific intervals or in response to certain events, such as the detection of a defective part by a sensor.

Renewable Energy: In wind farms, the board plays a crucial role in the control system of wind turbines. It monitors and adjusts the pitch of the turbine blades, as well as the speed of the generator, based on wind speed and direction data. This ensures optimal energy capture and conversion, maximizing the efficiency of the wind farm.

DS200RTBAG3AHC

Related Products

- GE DS200RTBAG3A: This is the parent relay terminal board of GE DS200RTBAG3AHC and lacks the full three – fold revision history of the latter. It may have slightly different functionality or performance characteristics, but still serves a similar purpose in the Mark V turbine control system.

- GE DS200RTBAG5AHC: Another relay terminal board in the series. It also has ten relays and is installed in the drive cabinet. However, the relay types (some are DPDT and others are 4PDT) and additional features like the presence of LEDs for each relay and specific connector types (16 – pin and 2 – pin) set it apart from the GE DS200RTBAG3AHC.

- GE Mark V Series Controllers: These controllers work in tandem with the GE DS200RTBAG3AHC to manage the overall operation of the turbine control system. They receive input signals processed by the relay terminal board and make decisions to control the turbine’s operation, such as adjusting its speed or power output.

- GE I/O Modules: Other I/O modules in the GE product range can be used in combination with the GE DS200RTBAG3AHC. They may offer different types of I/O capabilities, like analog input/output, which can complement the digital I/O functions of the GE DS200RTBAG3AHC in more complex industrial control setups.

- GE Power Supplies: Specific power supplies from GE are designed to work with the GE DS200RTBAG3AHC and other components in the system. They ensure a stable and reliable power supply, which is crucial for the proper functioning of the relay terminal board and the overall control system.

Installation and Maintenance

Pre – installation preparation: Before installing the GE DS200RTBAG3AHC, it is essential to turn off all power sources connected to the drive cabinet. This is to prevent any electrical accidents, as the board contains high energy when powered. Check the drive cabinet for any physical damage or debris that could affect the installation. Ensure that the board’s dimensions match the available space in the cabinet. Verify the compatibility of the board with other components in the system, especially in terms of electrical specifications and communication protocols.

Maintenance recommendations: Regularly inspect the GE DS200RTBAG3AHC for any signs of physical damage, such as cracks in the board or loose connections. Check the relays for proper operation; if a relay fails to function as expected, it can be replaced. Monitor the temperature of the drive cabinet, as overheating can damage the board. Since the board has high – energy components, always follow proper safety procedures when performing maintenance. If the board trips frequently, investigate the cause, which could be due to over – loading, short – circuits, or a malfunctioning device in the connected circuit.

Product Guarantee

General Electric stands firmly behind the quality of the GE DS200RTBAG3AHC. The product undergoes rigorous testing before leaving the factory to ensure it meets the highest quality standards. GE offers a comprehensive quality assurance program, which includes a standard warranty period. During this time, if any manufacturing defects are detected, GE will provide replacement or repair services free of charge. Their team of technical experts is available around the clock to offer support for installation, operation, and troubleshooting. This commitment reflects GE’s long – standing reputation for reliability and customer satisfaction, giving customers the confidence to rely on the GE DS200RTBAG3AHC for their industrial automation and control needs.