Description

Product Overview

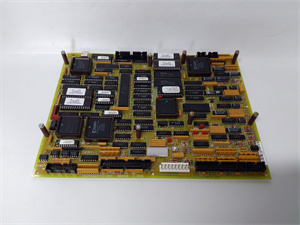

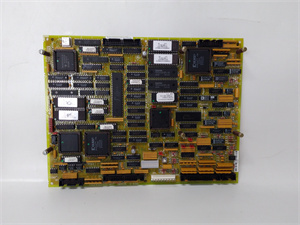

The GE DS200SDCCG1AEC is a drive control card developed by General Electric, specifically designed for the Mark V series turbine control systems. As a key component in industrial automation, it plays a crucial role in ensuring the stable operation of turbines. This card is based on GE’s patented Speedtronic technology, which has a long – standing reputation in the industry. With the GE DS200SDCCG1AEC, users can expect precise control over turbine – related operations. It serves as the primary controller for the automated drive in the Mark V series, allowing for seamless management of speed, torque, and other critical parameters. This not only enhances the efficiency of the turbine but also contributes to overall system reliability, making it an invaluable asset in industrial settings.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200SDCCG1AEC |

| Manufacturer | General Electric |

| Product Type | Drive Control Card |

| Series | Mark V |

| Microprocessors | 3 |

| Memory | Shared RAM accessible by multiple microprocessors |

| LED Indicators | 10 leds arranged in a row |

| Error Code Display | Some in BCD form, some in binary form |

| Reset Methods | Press reset button; apply +5 to +24 VDC to customer interface points on specific boards; reset through programmed software control; automatic reset via internal hardware watchdog protection |

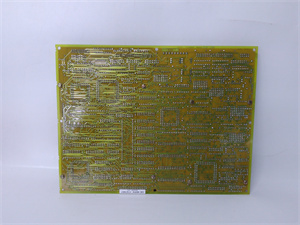

| PCB Coating | Normal coating |

| Artwork Revision | C |

| Functional Revision | 1A, 2E |

DS200SDCCG1AEC

Main Features and Advantages

Reliable and stable: The GE DS200SDCCG1AEC is engineered with a robust structure, enabling it to operate stably in harsh industrial environments. It comes equipped with short – circuit and overload protection features. These protective mechanisms can effectively safeguard the card and the connected equipment from potential damage caused by unexpected power surges, ensuring continuous operation.

Precise control: This card is equipped with a high – performance microprocessor and multiple programmable read – only memory (PROM) modules. It can accurately receive feedback signals from the turbine and control system. By leveraging advanced control algorithms, it adjusts the turbine’s speed and torque with high precision, optimizing the operation of the gas turbine for maximum efficiency.

Easy to troubleshoot: There are numerous troubleshooting tools integrated into the GE DS200SDCCG1AEC. For instance, the 10 LEDs arranged in a row on the board are extremely useful. Different flashing patterns of these LEDs can clearly indicate various error codes. This feature significantly helps maintenance personnel quickly identify and resolve problems. Additionally, diagnostic tools available on the drive can offer detailed performance information of all components within the drive, facilitating more efficient troubleshooting.

Precise control: This card is equipped with a high – performance microprocessor and multiple programmable read – only memory (PROM) modules. It can accurately receive feedback signals from the turbine and control system. By leveraging advanced control algorithms, it adjusts the turbine’s speed and torque with high precision, optimizing the operation of the gas turbine for maximum efficiency.

Easy to troubleshoot: There are numerous troubleshooting tools integrated into the GE DS200SDCCG1AEC. For instance, the 10 LEDs arranged in a row on the board are extremely useful. Different flashing patterns of these LEDs can clearly indicate various error codes. This feature significantly helps maintenance personnel quickly identify and resolve problems. Additionally, diagnostic tools available on the drive can offer detailed performance information of all components within the drive, facilitating more efficient troubleshooting.

DS200SDCCG1AEC

Application Field

The GE DS200SDCCG1AEC is mainly applied in the power generation industry, specifically in the control systems of steam, gas, and wind turbines. In power plants, it is responsible for regulating the speed and torque of turbines. By doing so, it ensures the stable operation of generators, which in turn guarantees a consistent and reliable power output. It also finds applications in industrial production processes that demand high – precision speed and torque control. In the chemical industry, for example, it can be used to control the rotation speed of high – speed rotating equipment. In the oil and gas sector, the GE DS200SDCCG1AEC is utilized in the control system of oil and gas extraction equipment. It helps maintain the efficient operation of such equipment, contributing to enhanced productivity and reduced downtime.

Related Products

- DS200SDCCG1: The original drive control board for the Mark V series automated drive assembly. It lacks the three significant product revisions present in the GE DS200SDCCG1AEC, making the GE DS200SDCCG1AEC potentially more advanced in terms of features and performance.

- SLCC: An auxiliary board related to the GE DS200SDCCG1AEC. It likely assists in certain control functions or data processing tasks, complementing the main card to improve overall system performance.

- LCC: Another auxiliary board that works in tandem with the GE DS200SDCCG1AEC. Together, they enhance the functionality of the overall control system, perhaps by providing additional processing power or communication capabilities.

- SPC: An auxiliary board within the Mark V series. It may be involved in signal processing and control tasks that are related to the operations of the GE DS200SDCCG1AEC, further optimizing the system’s performance.

- PSCB: This auxiliary board might be responsible for power supply and signal conditioning for the GE DS200SDCCG1AEC. It helps ensure that the main card receives stable power and clean signals for proper operation.

Installation and Maintenance

Pre – installation preparation: Before installing the GE DS200SDCCG1AEC, it is crucial to ensure that the installation environment meets the specified requirements. Check that the temperature and humidity are within the appropriate range. Thoroughly read the installation manual to understand the correct installation steps and wiring methods. Verify that the hardware jumpers on the board are set correctly according to the specific application needs. This careful pre – installation check will help prevent potential issues during the installation process.

Maintenance recommendations: Regularly monitor the operating status of the GE DS200SDCCG1AEC. Pay close attention to the flashing status of the LEDs, as they can indicate error codes. Clean the board periodically to prevent dust and dirt from accumulating, which could affect its performance. In case of any problems, it is advisable to have a trained professional conduct the repair. The testing equipment used should be approved and calibrated to ensure accurate test results, enabling effective troubleshooting and maintenance.

Maintenance recommendations: Regularly monitor the operating status of the GE DS200SDCCG1AEC. Pay close attention to the flashing status of the LEDs, as they can indicate error codes. Clean the board periodically to prevent dust and dirt from accumulating, which could affect its performance. In case of any problems, it is advisable to have a trained professional conduct the repair. The testing equipment used should be approved and calibrated to ensure accurate test results, enabling effective troubleshooting and maintenance.

Product Guarantee

General Electric stands firmly behind the quality of the GE DS200SDCCG1AEC. The product undergoes rigorous quality inspection before leaving the factory to ensure its high – performance and reliability. In terms of after – sales service, GE offers comprehensive technical support. This includes assistance with installation, configuration, and troubleshooting. If any quality issues arise within the warranty period, GE is committed to providing free repair or replacement services. This demonstrates GE’s confidence in the product and its dedication to ensuring customer satisfaction, giving users peace of mind when using the GE DS200SDCCG1AEC.