Description

1. Product Description

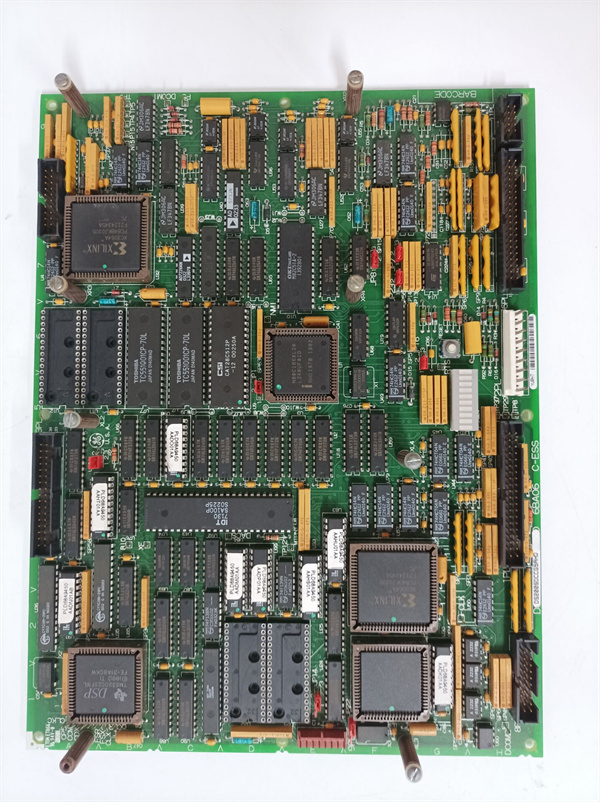

The GE DS200SDCCG5AHD is a high-performance drive control board designed for GE’s Mark V Speedtronic turbine control system, a legacy series renowned for its patented control technology in power generation and industrial applications. As a critical component, the DS200SDCCG5AHD manages drive and exciter operations, processing signals and coordinating with other system modules to ensure precise turbine control. It features a modular architecture with three microprocessors (drive control, motor control, and co-motor processors) and advanced Xilinx chips, enabling real-time data processing and configuration management. The board supports daughterboard expansion via vertical pin connectors and standoffs, enhancing its flexibility for complex industrial setups.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Power Supply | 24 VDC (±10%) |

| Processor | Xilinx chips, drive/motor/co-motor processors |

| Memory | RAM for multi-processor access; EEPROM for configuration storage |

| Interfaces | Vertical pin connectors for daughterboards, signal processing interfaces |

| Operating Temperature | -20°C to 60°C |

| Dimensions | Standard Mark V rack form factor (16 cm × 16 cm × 12 cm) |

| Weight | 0.8 kg (lightweight for rack installation) |

| Compatibility | GE Mark V Speedtronic system; replaced by DS215SDCC (non-backward compatible) |

| Revisions | G1, G3, G4, G5 (G2 not manufactured) |

DS200SDCCG5AHD

3. Advantages and Features

- High Reliability: Industrial-grade components ensure an MTBF exceeding 100,000 hours, critical for continuous operation in power plants.

- Modular Design: Standoff-mounted daughterboards allow scalability for LAN connectivity or advanced signal processing.

- Diagnostic Capabilities: Built-in error detection and configuration validation reduce downtime.

- Firmware Flexibility: User-configurable EEPROM (one module) and factory-programmed EEPROMs (four modules) enable quick parameter adjustments.

- Legacy Support: Ideal for retrofitting or maintaining Mark V systems, with clear labeling (GE logo, board ID) and drilled mounting holes.

4. Application Areas and Application Cases

- Application Areas: Gas/steam turbine power plants, industrial drive systems, and legacy Mark V Speedtronic installations.

- Application Case: A European power plant used the DS200SDCCG5AHD to modernize a Mark V system, achieving 99.9% uptime over five years. The board’s modular design allowed seamless integration with existing exciters, reducing retrofit costs by 20%.

5. Competitor Comparison

Compared to legacy control boards, the DS200SDCCG5AHD offers superior integration with Mark V systems, leveraging GE’s proprietary Speedtronic technology. Its multi-processor architecture and daughterboard expansion outperform single-processor alternatives, while its MTBF surpasses industry standards for similar legacy components.

DS200SDCCG5AHD

6. Selection Recommendations

- Compatibility: Verify Mark V system version (G1/G3/G4/G5) and avoid backward compatibility issues with DS215SDCC.

- Configuration Needs: Ensure EEPROM capacity matches application complexity (factory vs. user-configurable modules).

- Environment: Confirm temperature/humidity ratings align with installation conditions (e.g., control cabinets).

- Budget: Balance upfront cost with long-term maintenance savings (e.g., diagnostic features reduce repair time).

7. Precautions

- Installation: Follow GE’s manual for proper grounding, cable routing, and static discharge protection.

- Configuration: Use factory-provided EEPROMs for critical parameters; validate user-configured settings.

- Maintenance: Schedule firmware updates and periodic inspections. Replace with GE-certified components to avoid compatibility risks.

- Retrofit Note: DS215SDCC upgrades require system architecture changes—consult GE documentation before migration.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for DS200SDCCG5AHD and other automation spare parts. We provide sales and technical support. Visit our website www.xydcontrol.com or contact us for tailored solutions.